Numerical control machine tool

A numerically controlled machine tool, debris technology, applied to metal processing machinery parts, separation methods, filtration and separation, etc., can solve the problems that debris cannot be cleaned by brushes, debris cannot be blown away, etc. Achieve the effect of improving convenience, improving protection effect and preventing splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

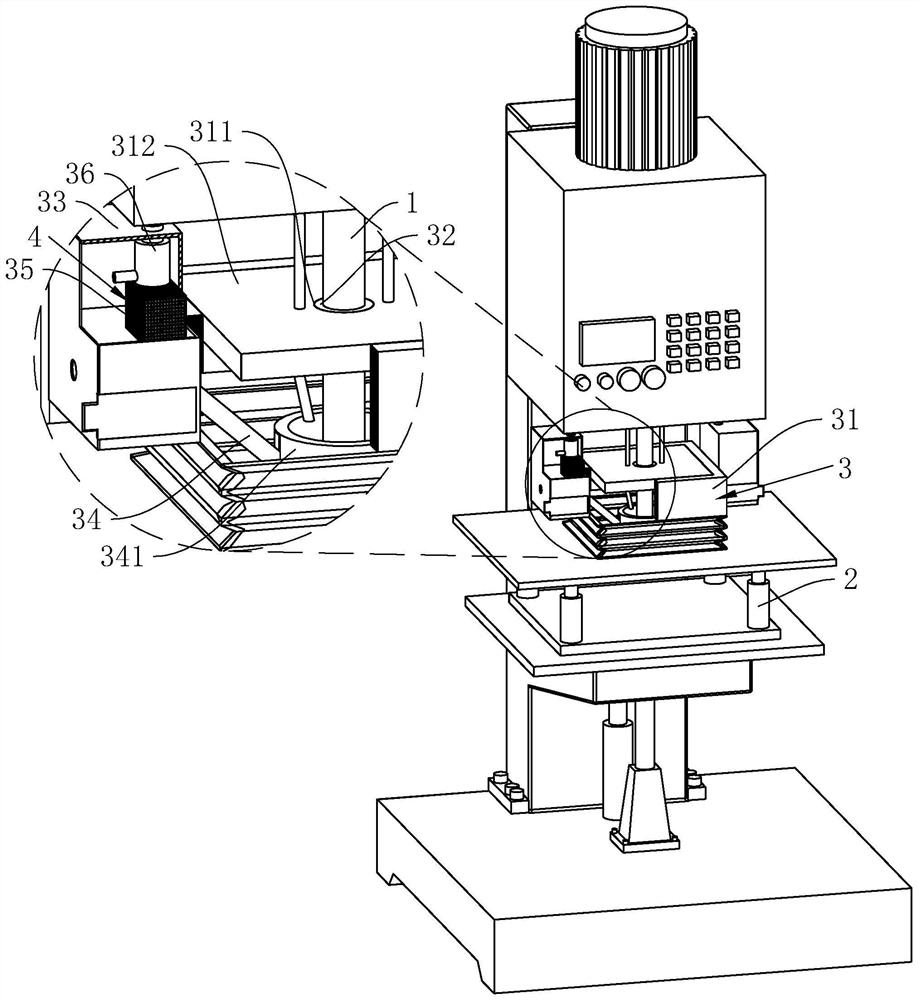

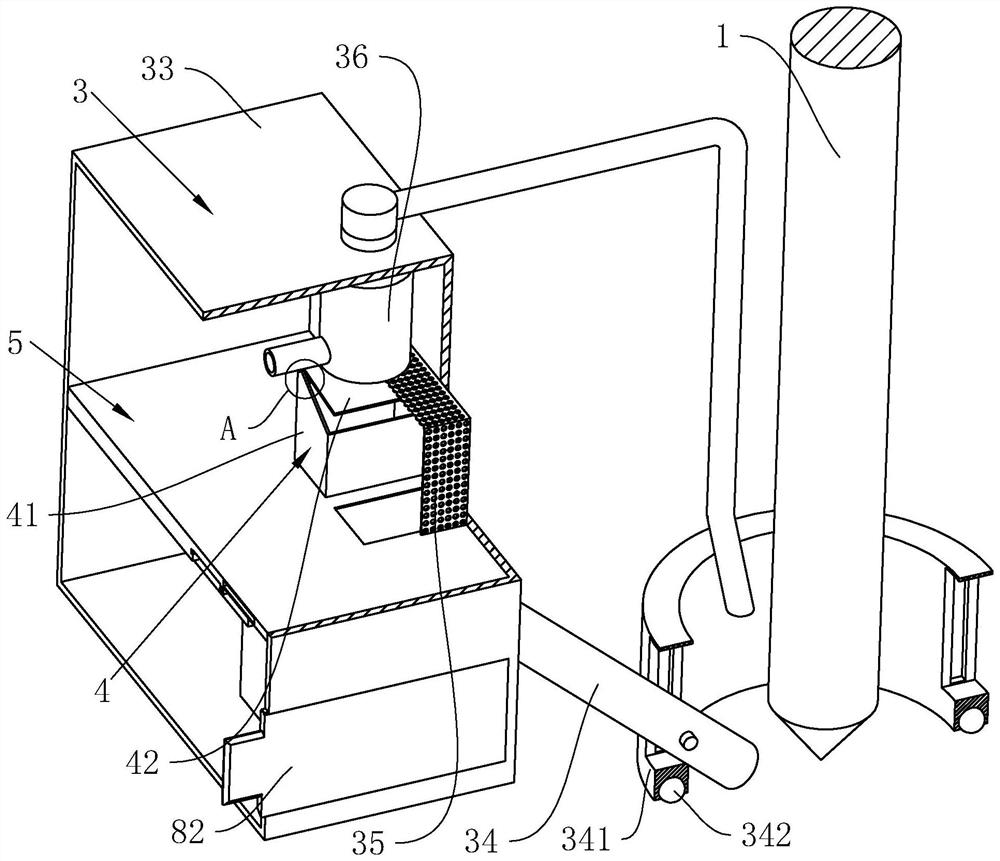

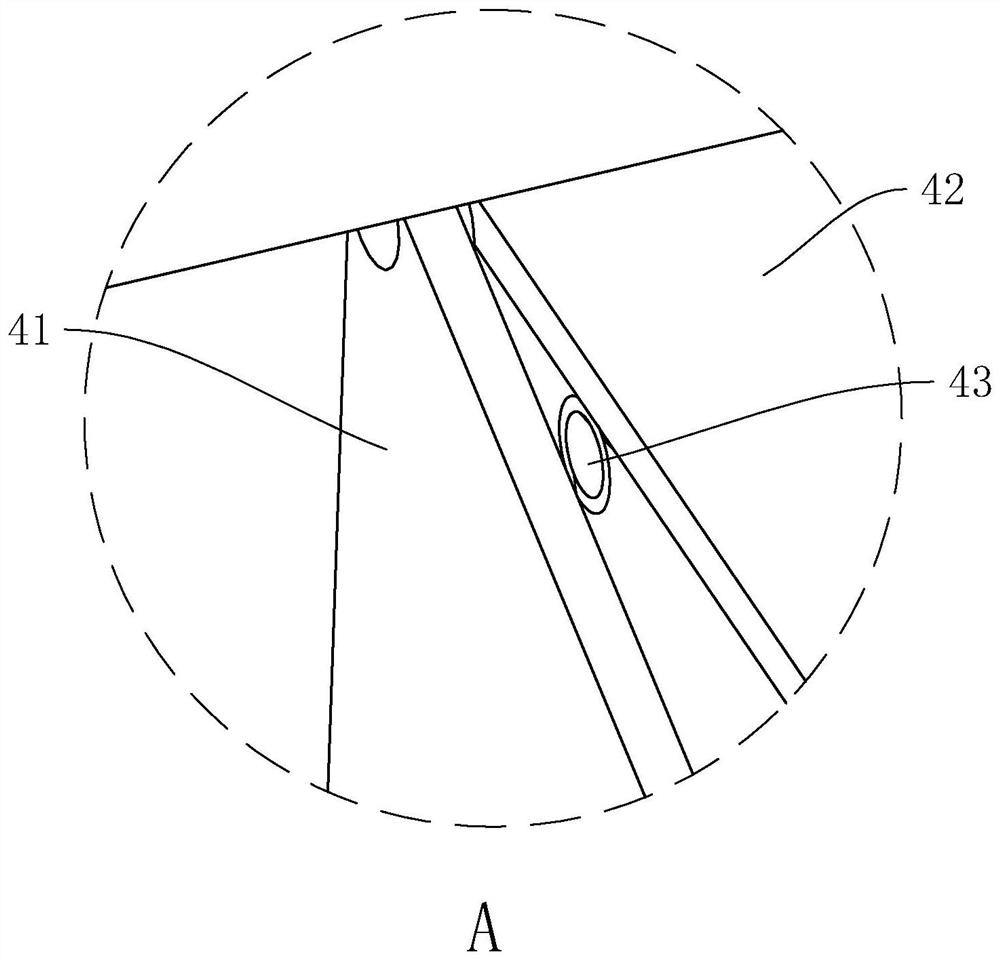

[0043] refer to figure 1 As shown, in order to recover the debris generated by the drill bit 1 and to synchronously cool the drill bit 1, in this embodiment, a debris cleaning device 3 is arranged between the telescopic seat and the support plate in the processing area; The debris cleaning device 3 includes a debris cover 31, a fixed bearing 32, a device box 33, a suction pipe 34, a filter cover 35, a high-pressure water pump 36 and a circulating storage device 4; Cover installation, the chip cover 31 is provided with a mounting groove 311 for the drill bit 1 to be installed through, and the bottom of the chip cover 31 is in conflict with the top of the plate to be cut, and the lower half of the chip cover 31 is set as a retractable material cover The fixed bearing 32 is arranged between the outer side wall of the drill bit 1 and the side wall of the installation groove 311 to install the debris cover 31, and the outer side wall of the fixed bearing 32 is fixedly arranged on t...

Embodiment 2

[0051] refer to Figure 4 As shown, on the basis of the first embodiment, in order to further reduce the labor of the operator and enable the device to realize automatic operation, the corresponding automatic switch mechanism 6 is installed in the control area in the device box 33, and the automatic switch mechanism 6 includes The delivery pipe 61, the drive rod 62, the limit rod 63, the thrust spring 64 and the water pump switch 65; Therefore, when one end of the suction port of the suction pipe 34 slides in the direction of the drill bit 1 against the plate to be cut, the connecting end of the suction pipe 34 and the conveying pipe 61 moves downward at the same time, that is, the conveying pipe 61 is synchronously driven to move downward; the blocking plate 5 There is a sliding groove 51 for sliding installation of the conveying pipe 61 . It should be noted that the conveying pipe 61 will only move in the sliding groove 51 and will not be separated from the blocking plate 5 ...

Embodiment 3

[0056] refer to Figure 4 , Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, in order to ensure that the device can realize automatic debris cleaning and collection, the third embodiment is provided with the relevant technology of debris cleaning and collection, the specific structure is as follows :

[0057] An impurity collection mechanism 7 is installed in the blocking plate 5, and the impurity collection mechanism 7 includes a receiving cylinder 71, a transmission column 72, a transmission bar 73, a first guide block 74, a first diamond block 75, a connecting rod 76 and an isolation plate 77; The material cylinder 71 is fixed on the lower side of the blocking plate 5, and the blocking plate 5 is provided with a through-hole 53 which connects the liquid supply area with the inner cavity of the receiving cylinder 71. The through-hole 53 is located in the covering area of the filter cover 35. When the discharge box 41 discharges debris and cooling liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com