Net zero discharge treatment device for electroplating wastewater and treatment method thereof

A technology for electroplating wastewater and treatment device, which is applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of solving the poor treatment effect, the overall structure design is compact, and the aggregation treatment is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

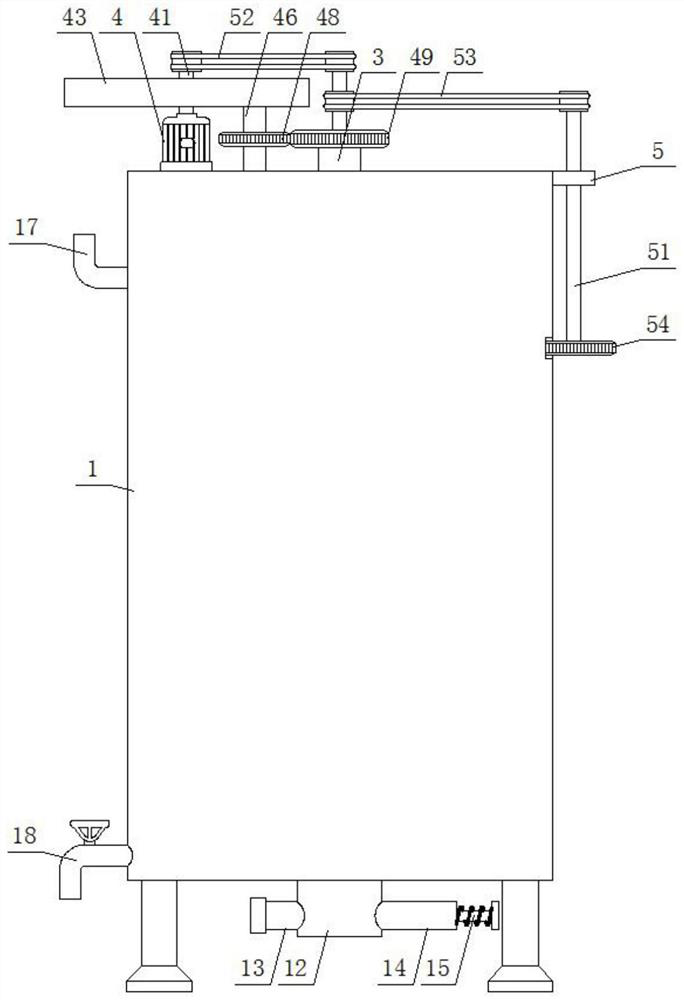

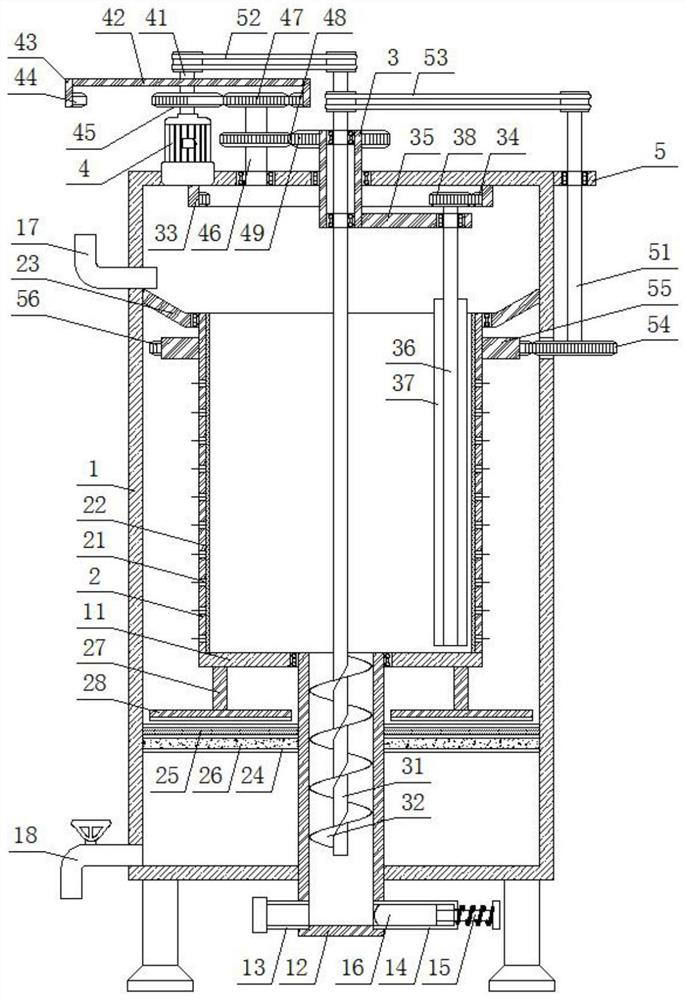

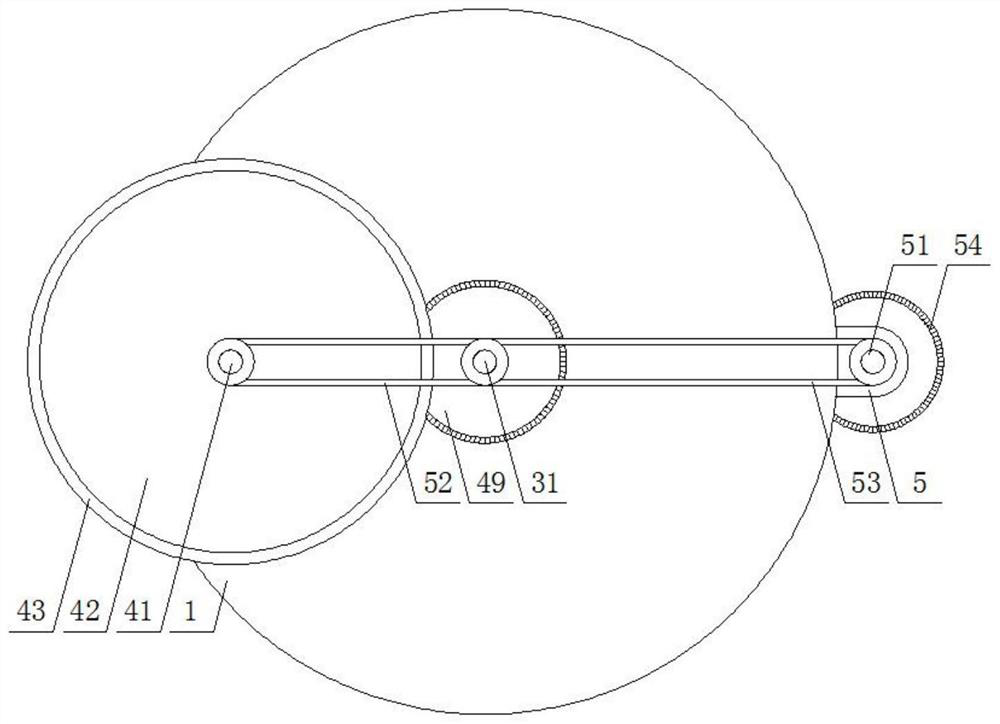

[0041] Embodiment 1: This embodiment provides a net-zero discharge treatment device for electroplating wastewater, see Figure 1-6Specifically, it includes a processing box 1, the processing box 1 is a vertically placed circular box, the middle and lower parts of the processing box 1 are provided with a centrifugal disc 11 placed in the air, and the middle part of the bottom surface of the centrifugal disc 11 is provided with a through-fixed first A bearing ring, the middle part of the bottom surface of the treatment box 1 is provided with a sedimentation cylinder 12 which is fixed through and fixed, and the top part of the sedimentation cylinder 12 is inserted in the first bearing ring and fixed concentrically with the first bearing ring, and is located in the processing box 1 for sedimentation A filter assembly is installed on the cylinder 12;

[0042] A conical ring 23 fixed concentrically is arranged in the upper part of the processing box 1, a second bearing ring fixed co...

Embodiment 2

[0054] Embodiment 2: In Embodiment 1, the waste water after centrifugal filtration by the biological filtration membrane still has the problem of odor and incomplete purification. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0055] Specifically, see figure 2 and Figure 4 , the filter assembly includes deodorant 25, activated carbon 26, the middle and upper part of the sedimentation cylinder 12 is sleeved with three concentrically fixed grid disks 24, and the outer edge of each grid disk 24 is fixed with the inner wall of the treatment box 1, The deodorant 25 is filled between the two mesh discs 24 located above, and the activated carbon 26 is filled between the two mesh discs 24 located below; a pair of limit rods 27 are provided on both sides of the bottom surface of the centrifugal disc 11, each The bottom end of the limit rod 27 is provided with vertically fixed limit plates 28, and each limit plate 28 slides along the top surface of the grid...

Embodiment 3

[0056] Embodiment 3: In Embodiment 1, there is also the problem that the sediment in the precipitation cylinder cannot be discharged in time. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0057] Specifically, see figure 2 , the bottom of one side of the sedimentation cylinder 12 is provided with a sewage pipe 13 that is connected through and fixed, the outer end of the sewage pipe 13 is provided with a sealing cover, and the bottom of the other side of the sedimentation cylinder 12 is provided with a through-fixed piston cylinder 14. The inside of 14 is provided with an elongated piston 16 that is slidably connected, the outer port of the piston cylinder 14 is inserted with a T-shaped piston rod 15 that is slidably connected, and the inner end of the T-shaped piston rod 15 is fixedly connected to the elongated piston 16. A tension spring is sleeved on the outer section of the piston rod 15 ; open the threaded cover and push the T-shaped piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com