Carbon quantum dot fluorescent anti-forgery ink as well as preparation method and application thereof

The technology of carbon quantum dots and anti-counterfeiting ink is applied in the field of carbon quantum dot fluorescent anti-counterfeiting ink and its preparation, which can solve the problems that the fluorescent pattern cannot be arbitrarily set, the phenomenon of phase separation is easy to occur, and the anti-counterfeiting effect is lost, and the anti-counterfeiting effect is strong and the anti-counterfeiting effect is lost. Strong fluorescence and stability, good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

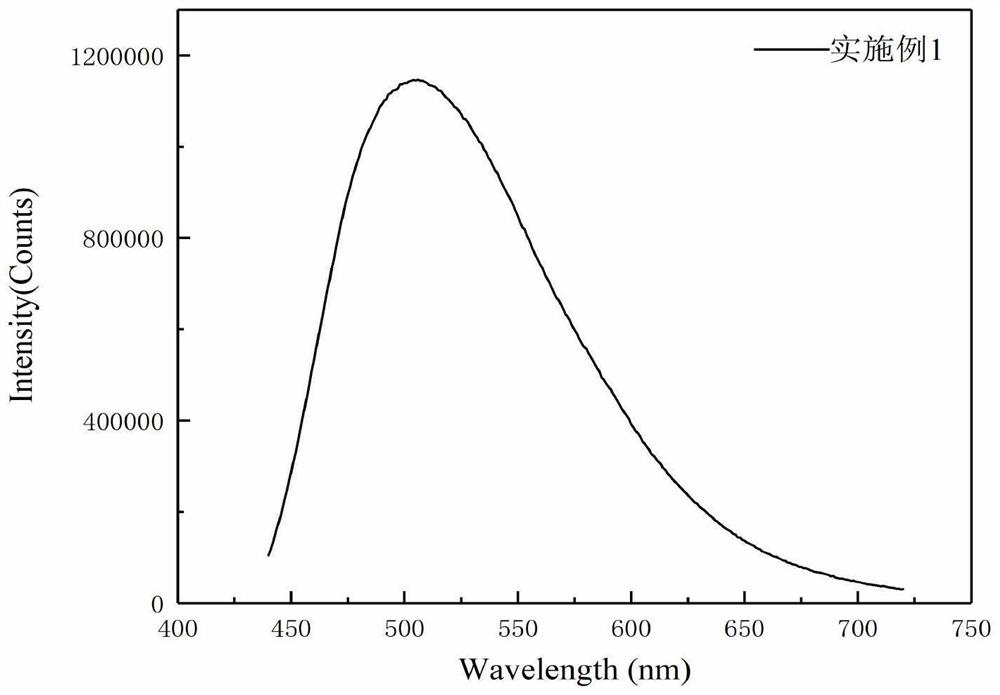

Embodiment 1

[0038] A preparation method of carbon quantum dot fluorescent anti-counterfeiting ink, specifically comprising the following steps:

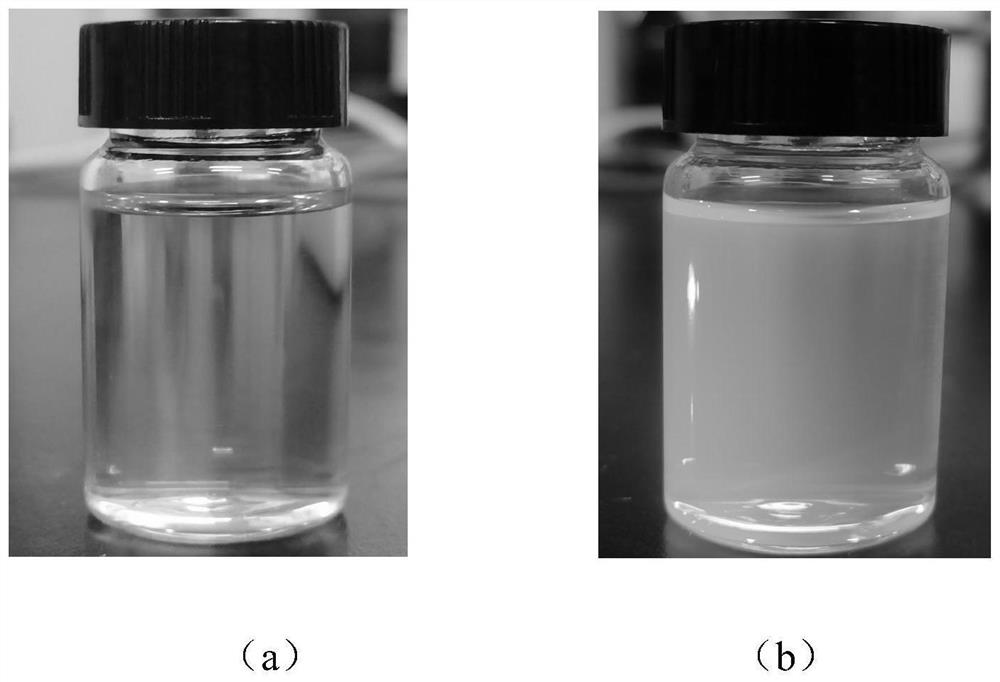

[0039] 1) Weigh 1g of anhydrous citric acid, 1ml of diethylenetriamine, and 2g of acrylamide to dissolve in 30ml of deionized water, and ultrasonically disperse for 20min under 80W power to obtain a mixed solution, and then put the mixed solution into the stainless steel of the PTFE liner The reaction kettle was placed in an oven at 180° C. for hydrothermal reaction for 6 hours. After the reaction was completed, it was naturally cooled to room temperature, and then the reaction kettle was taken out to obtain a carbon quantum dot solution.

[0040] 2) Transfer the carbon quantum dot solution in the reaction kettle to a centrifuge tube, centrifuge at 8000 r / min for 15 minutes, and then take out the supernatant. The dialysis bag with a molecular weight cut-off of 1000 Da was soaked in deionized water for 10 minutes, and the supernatant obtained by ...

Embodiment 2

[0045] A preparation method of carbon quantum dot fluorescent anti-counterfeiting ink, specifically comprising the following steps:

[0046]1) Weigh 1g of anhydrous citric acid, 1ml of diethylenetriamine, and 2g of acrylamide to dissolve in 30ml of deionized water, ultrasonically disperse for 20min under 80W power to obtain a mixed solution, and then put the mixed solution into the stainless steel of the PTFE liner The reaction kettle was placed in an oven at 180° C. for hydrothermal reaction for 4 hours. After the reaction was completed, it was naturally cooled to room temperature, and then the reaction kettle was taken out to obtain a carbon quantum dot solution.

[0047] 2) Transfer the carbon quantum dot solution in the reaction kettle to a centrifuge tube, centrifuge for 15 minutes at a rotational speed of 8000 r / min, and then take out the supernatant. The dialysis bag with a molecular weight cut-off of 1000 Da was soaked in deionized water for 10 minutes, and the superna...

Embodiment 3

[0052] The present embodiment prepares the carbon quantum dot fluorescent anti-counterfeiting ink according to the following steps:

[0053] 1) Weigh 1g of anhydrous citric acid, 1ml of diethylenetriamine, and 2g of acrylamide to dissolve in 30ml of deionized water, ultrasonically disperse for 20min under 80W power to obtain a mixed solution, and then put the mixed solution into the stainless steel of the PTFE liner The reaction kettle was placed in an oven at 180° C. for hydrothermal reaction for 8 hours. After the reaction was completed, it was naturally cooled to room temperature, and then the reaction kettle was taken out to obtain a carbon quantum dot solution.

[0054] 2) Transfer the carbon quantum dot solution in the reaction kettle to a centrifuge tube, centrifuge for 15 minutes at a rotational speed of 8000 r / min, and then take out the supernatant. The dialysis bag with a molecular weight cut-off of 1000 Da was soaked in deionized water for 10 minutes, and the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com