Large metallurgical slag pot and manufacturing method thereof

A metallurgical slag, large-scale technology, applied in the field of large-scale metallurgical slag tank and its manufacturing, can solve the problems of large slag block, difficult to assemble and disassemble the grid, difficult slag separation, etc., to prevent sintering, reduce the difficulty of separation, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

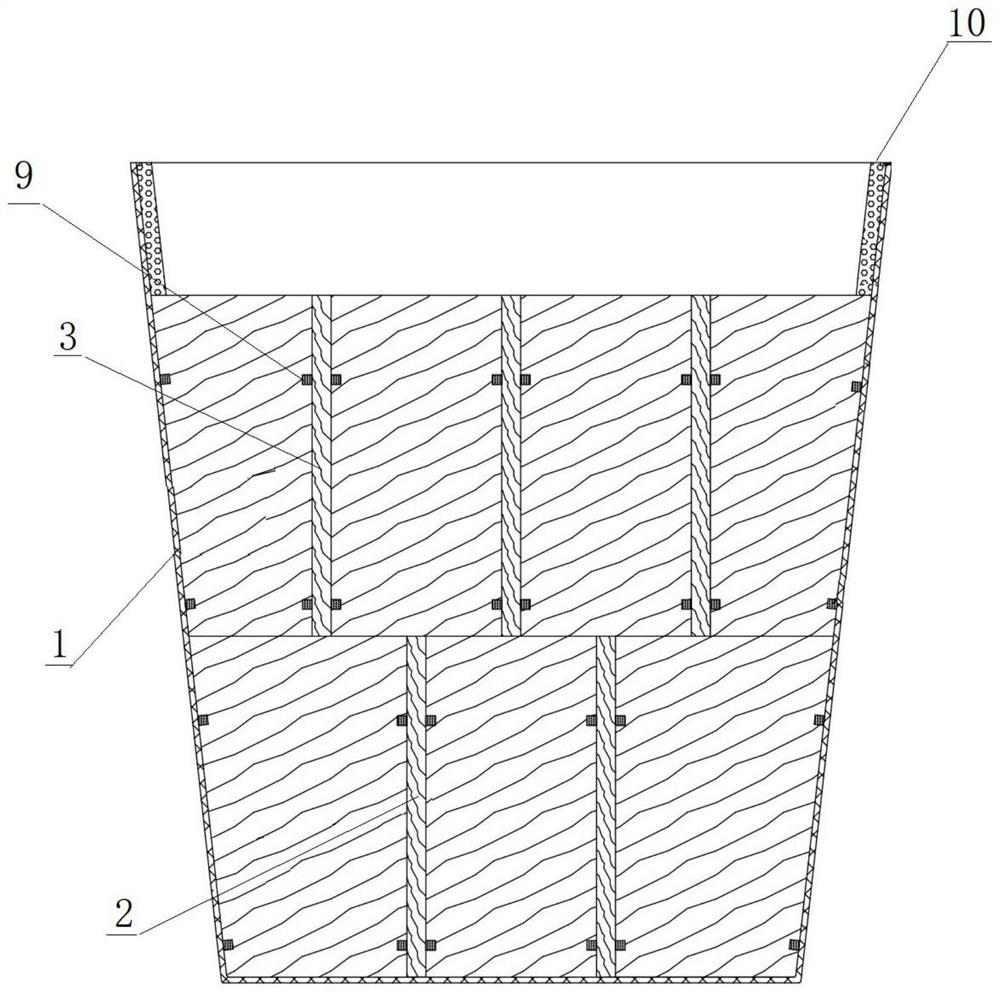

[0039] like figure 1 As shown, a large metallurgical slag tank includes a tank body 1. The tank body 1 is provided with a lower grid structure 2 and an upper grid structure 3 from bottom to top, and the lower grid structure 2 is a well-shaped structure with two horizontal and two vertical. , the upper grid structure 3 is a three-horizontal and three-longitudinal structure, the lower grid structure 2 and the upper grid structure 3 are processed by grid refractory material, the tank body 1 is processed by the tank body refractory material, and the interior of the tank body 1 There are grid positioning clamps 9 for positioning the lower grid structure 2 and the upper grid structure 3, and the tank body 1 is provided with beading bars 10 around the inner side.

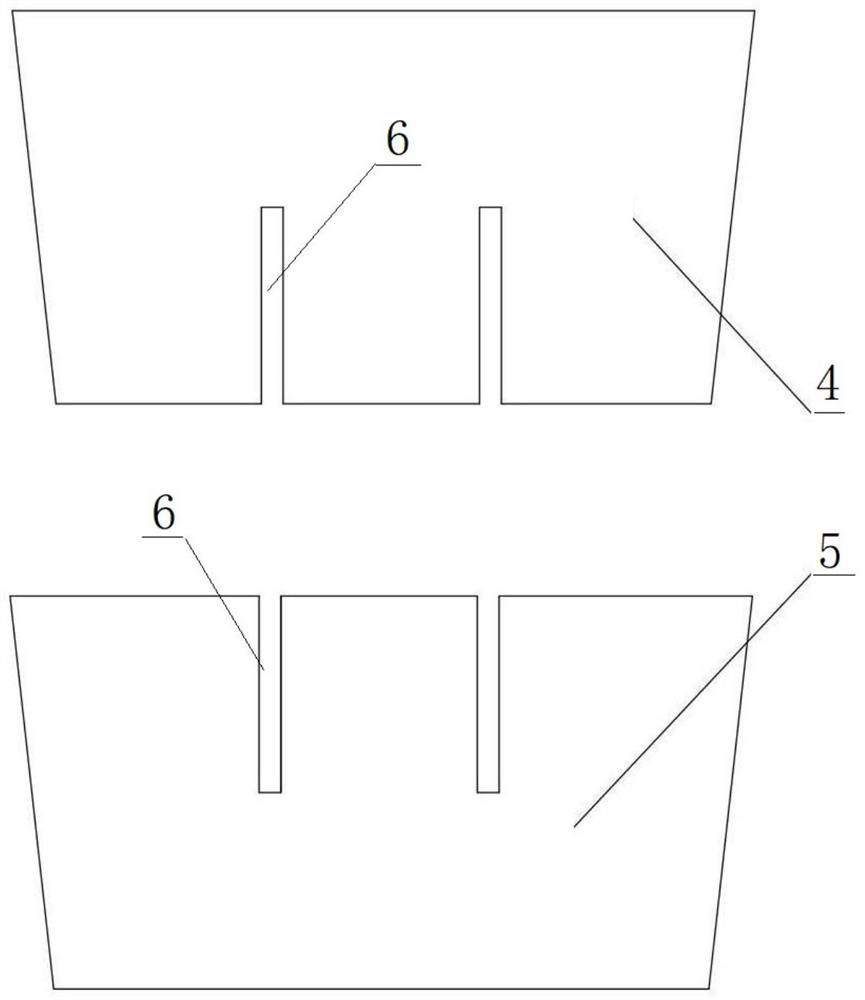

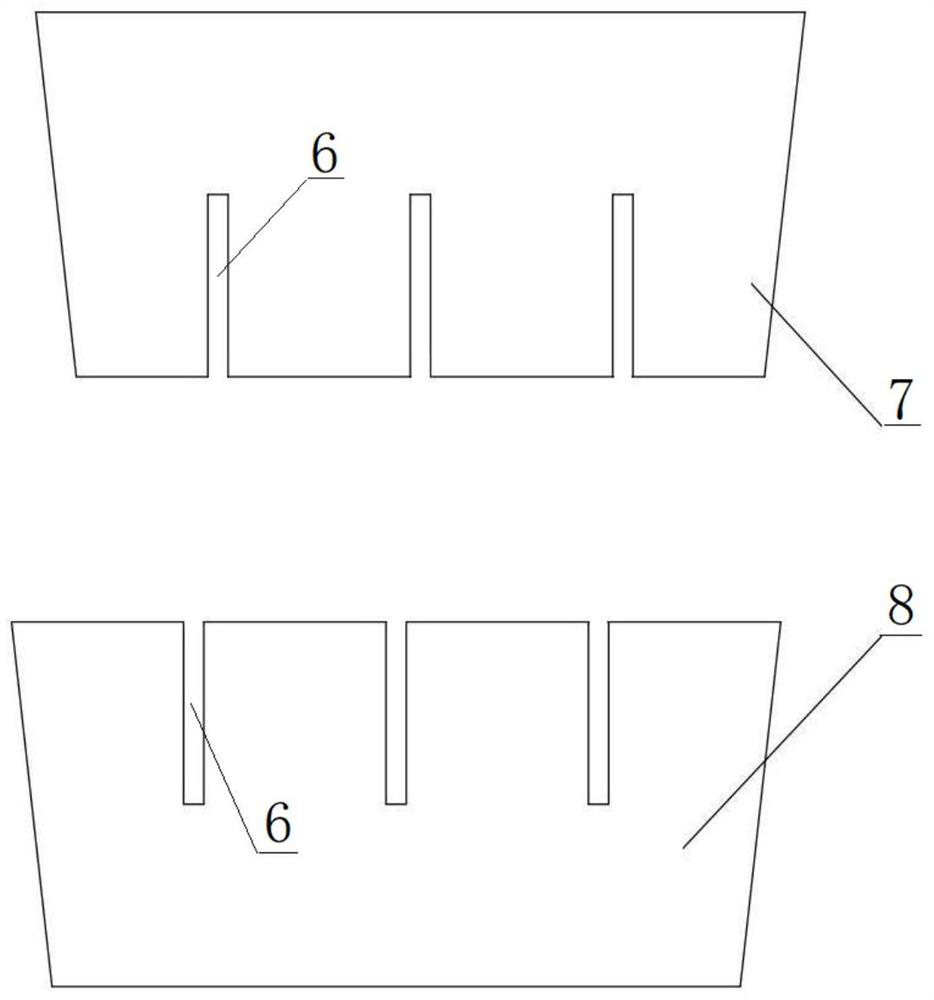

[0040] Among them, combined figure 1 and figure 2 As shown, the lower grid structure 2 includes two horizontal lower refractory prefabricated panels 4 and two longitudinal lower refractory prefabricated panels 5. The ho...

Embodiment 2

[0057] like figure 1 As shown, a large metallurgical slag tank includes a tank body 1. The tank body 1 is provided with a lower grid structure 2 and an upper grid structure 3 from bottom to top, and the lower grid structure 2 is a well-shaped structure with two horizontal and two vertical. , the upper grid structure 3 is a three-horizontal and three-longitudinal structure, the lower grid structure 2 and the upper grid structure 3 are processed by grid refractory material, the tank body 1 is processed by the tank body refractory material, and the interior of the tank body 1 There are grid positioning clamps 9 for positioning the lower grid structure 2 and the upper grid structure 3 , and the tank body 1 is provided with beading bars 10 along the inner periphery.

[0058] Among them, combined figure 1 and figure 2 As shown, the lower grid structure 2 includes two horizontal lower refractory prefabricated panels 4 and two longitudinal lower refractory prefabricated panels 5. T...

Embodiment 3

[0075] like figure 1 As shown, a large metallurgical slag tank includes a tank body 1. The tank body 1 is provided with a lower grid structure 2 and an upper grid structure 3 from bottom to top, and the lower grid structure 2 is a well-shaped structure with two horizontal and two vertical. , the upper grid structure 3 is a three-horizontal and three-longitudinal structure, the lower grid structure 2 and the upper grid structure 3 are processed by grid refractory material, the tank body 1 is processed by the tank body refractory material, and the interior of the tank body 1 There are grid positioning clamps 9 for positioning the lower grid structure 2 and the upper grid structure 3 , and the tank body 1 is provided with beading bars 10 along the inner periphery.

[0076] Among them, combined figure 1 and figure 2 As shown, the lower grid structure 2 includes two horizontal lower refractory prefabricated panels 4 and two longitudinal lower refractory prefabricated panels 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com