Rust steel simulation method based on surface random roughness

A simulation method and roughness technology, applied in 3D modeling, complex mathematical operations, instruments, etc., can solve the problems of limited application range, ignoring the overall rust characteristics of the rusted surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

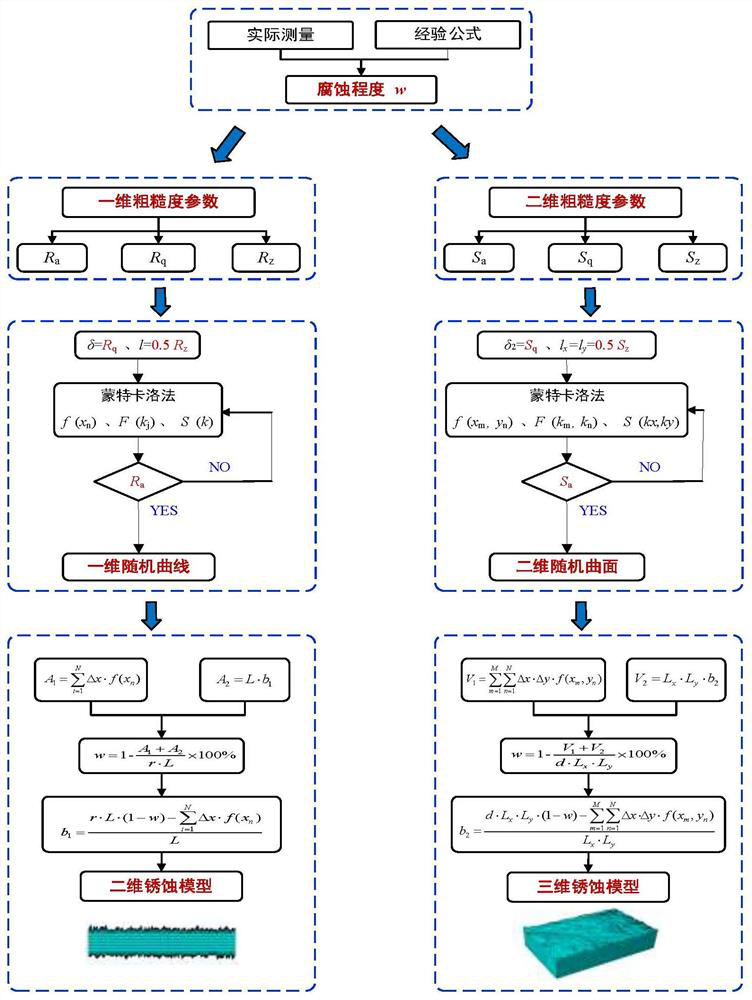

[0058] The present invention will be further described below with reference to the accompanying drawings. according to image 3 The steps shown use the proposed method to generate a finite element model of Q355B steel subjected to atmospheric corrosion.

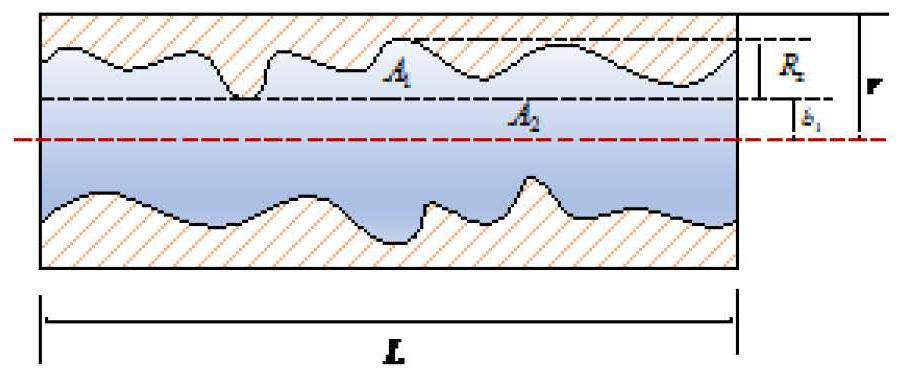

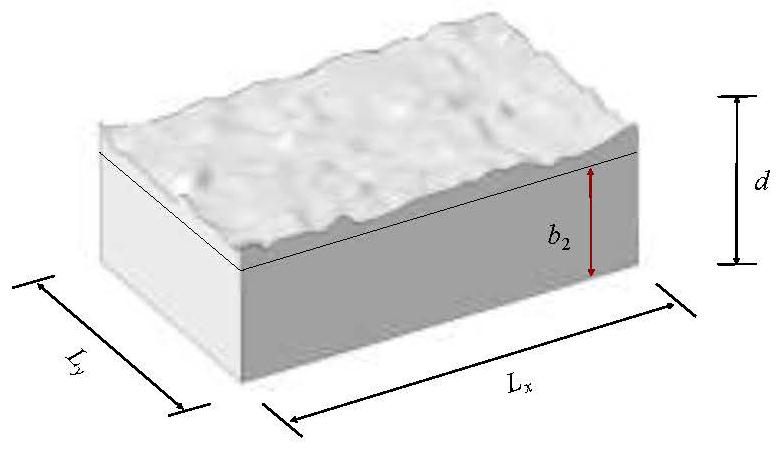

[0059] For the two-dimensional model, it is assumed that the original size length (L) is 100mm, the height (2r) is 7mm, and the corrosion rate w=13.83%. Calculate the roughness parameter R of the two-dimensional model surface of the rusted steel corresponding to the rust rate w according to formulas (1)-(3). a , R q with R z . will δ 1 =R q , l=0.5R z Substitute into formula (7) and formula (8) to generate a one-dimensional random surface, such as Figure 4 shown. Calculate parameter b according to formula (13) 1 , determine the distance from the rusted surface to the midline to form a two-dimensional model, such as Figure 5 shown. The obtained model is imported into the finite element mesh to obtain a two-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com