NiSe2-CNT/S composite lithium-sulfur battery positive electrode material and preparation method thereof

A technology of cathode materials and composite materials, which is applied in the field of NiSe2-CNT/S composite lithium-sulfur battery cathode materials and its preparation, can solve the problems of high cost, low output, complex modification methods, etc., and achieve easy operation, low cost, The effect of suppressing the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A NiSe 2 -CNT / S composite lithium-sulfur battery cathode material, prepared by the following method:

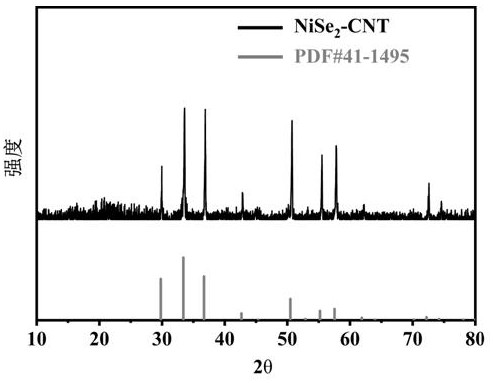

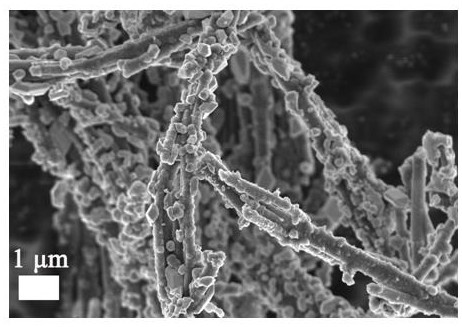

[0034] Disperse 0.58g of nickel nitrate and 3g of urea in 70mL of deionized water, and ultrasonically stir until completely dissolved; then add 0.1g of CNT, stir for 15min, transfer it into the reaction kettle, and react at 100°C for 6h; after the reaction is completed, use ethanol and water for the product , centrifugally washed for 3-5 times, and then put into an oven to dry at 60°C; 0.15g of the dried product is weighed and mixed with 0.3g of selenium powder and ground evenly; then transferred to a tube furnace for calcination at 600°C for 2 hours to obtain NiSe 2 -CNT composite; then NiSe 2 - CNT composite material and sulfur powder are mixed in a mass ratio of 3:7 and ground evenly, and then annealed at 155 °C for 12 h in an argon atmosphere to obtain NiSe 2 -CNT / S lithium-sulfur battery cathode material.

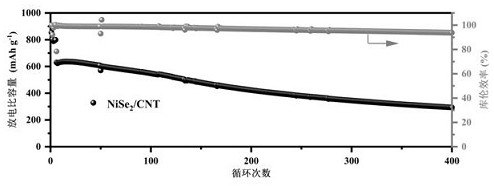

[0035] After testing, the lithium-sulfur battery catho...

Embodiment 2

[0037] A NiSe 2 -CNT / S composite lithium-sulfur battery cathode material, prepared by the following method:

[0038]Disperse 1.16g of nickel nitrate and 3g of urea in 70mL of deionized water, and ultrasonically stir until completely dissolved; then add 0.2g of CNT, stir for 15min, transfer it into a reaction kettle, and react at 120°C for 6h; after the reaction is completed, use ethanol and water for the product , centrifugally washed 3-5 times, and then placed in an oven to dry at 60°C; 0.2g of the dried product was mixed with 0.6g of selenium powder and ground evenly; then transferred to a tube furnace for calcination at 600°C for 2 hours to obtain NiSe 2 -CNT composite; then NiSe 2 - CNT composite material and sulfur powder are mixed in a mass ratio of 3:7 and ground evenly, and then annealed at 155 °C for 12 h in an argon atmosphere to obtain NiSe 2 -CNT / S lithium-sulfur battery cathode material.

[0039] After testing, the lithium-sulfur battery cathode material obtain...

Embodiment 3

[0041] A NiSe 2 -CNT / S composite lithium-sulfur battery cathode material, prepared by the following method:

[0042] Disperse 1.16g of nickel nitrate and 3g of urea in 70mL of deionized water, and ultrasonically stir until completely dissolved; then add 0.1g of CNT, stir for 15min, transfer it into the reaction kettle, and react at 120°C for 6h; after the reaction is completed, use ethanol and water for the product , centrifugally washed 3-5 times, and then placed in an oven to dry at 60 °C; 0.3 g of the dried product was weighed and mixed with 0.6 g of selenium powder and ground evenly; then transferred to a tube furnace for calcination at 600 °C for 2 hours to obtain NiSe 2 -CNT composite; then NiSe 2 - CNT composite material and sulfur powder are mixed in a mass ratio of 3:7 and ground evenly, and then annealed at 155 °C for 12 h in an argon atmosphere to obtain NiSe 2 -CNT / S composite lithium-sulfur battery cathode material.

[0043] After testing, the lithium-sulfur ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com