Petroleum drilling petroleum additive production reaction kettle device

A technology for oil drilling and reaction kettles, applied in mixers with rotary stirring devices, chemical/physical/physical-chemical stationary reactors, transportation and packaging, etc. , increase the response time and other problems, to achieve the effect of shortening maintenance time, improving mixing efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

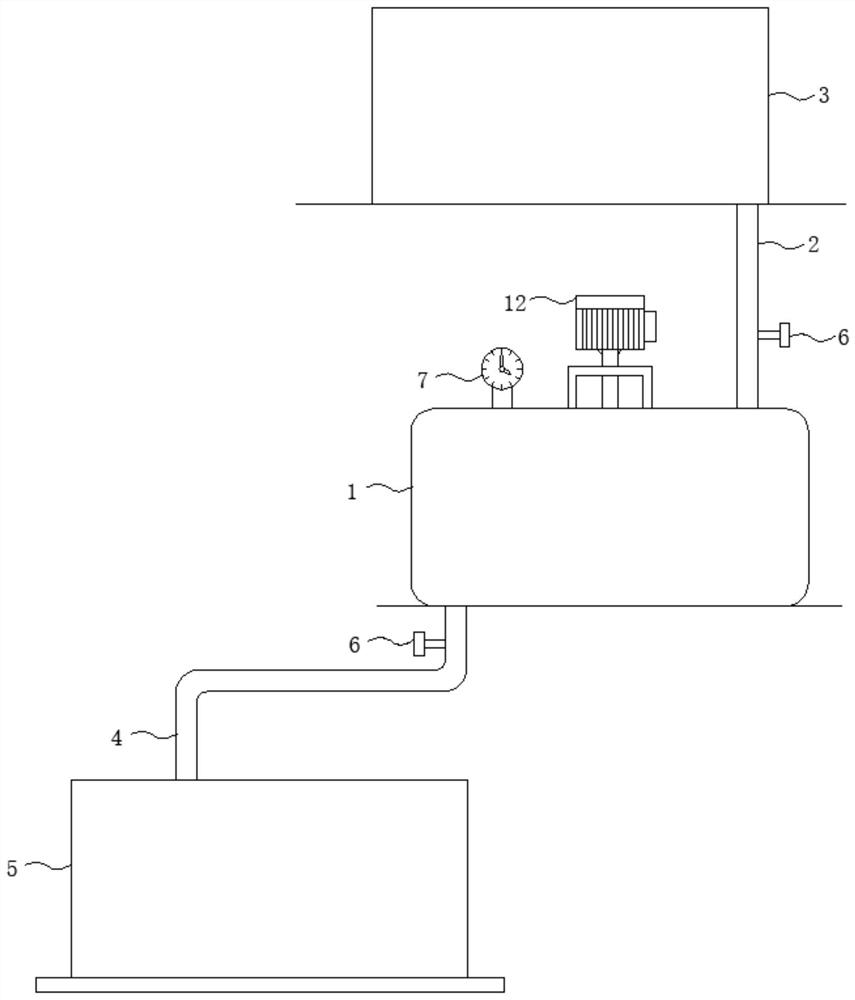

[0041] see attached Figure 1-6 As shown, the present invention is a kind of oil drilling oil auxiliary production reactor device, comprising a reactor body 1, the upper part of the reactor body 1 is communicated with the first storage tank 3 through the feed pipe 2, and the bottom of the reactor body 1 is connected with the first storage tank 3 through the discharge pipe 4 Connected with the second storage tank 5, the feed pipe 2 and the discharge pipe 4 are provided with valves 6; the reactor body 1 is provided with a mixing component 11, and the mixing component 11 is driven by the motor 12 ; Wherein, under the drive of the motor 12, the mixing component 11 can be rotated, and then the materials entering the reactor body 1 can be fully mixed, and the interior of the reactor body 1 can be cleaned at the same time.

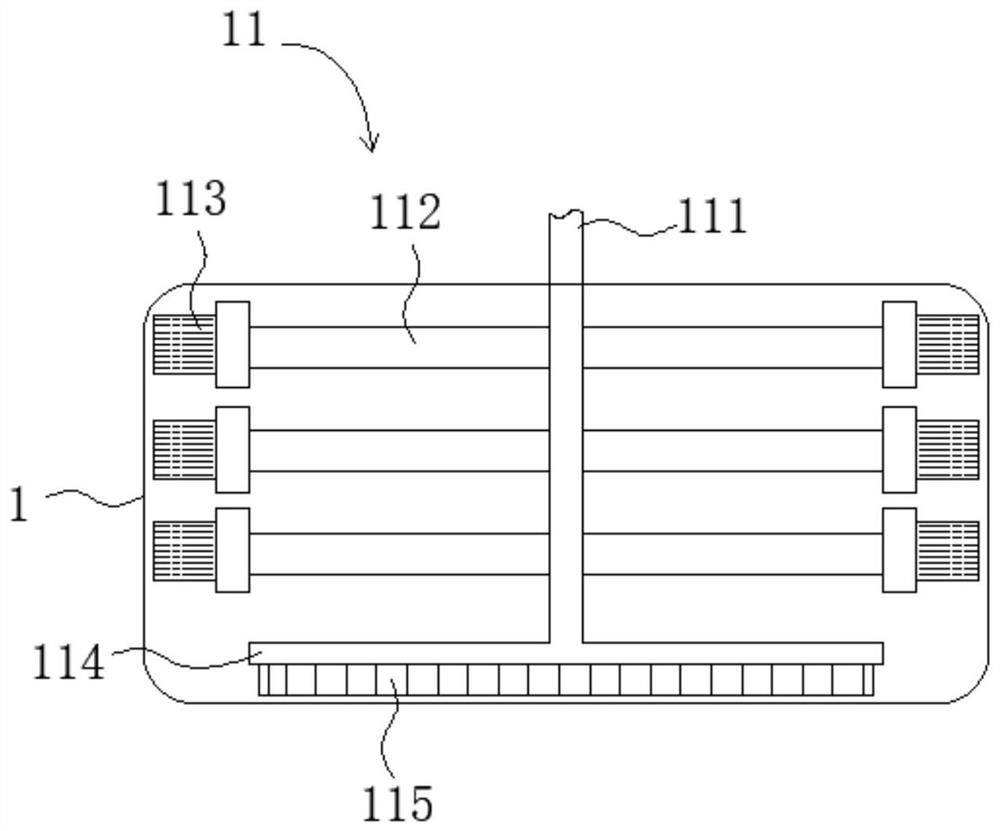

[0042] In this embodiment, the mixing assembly 11 includes a rotating shaft 111 and several layers of connecting rods 112 disposed on the rotating shaft 111 . Th...

Embodiment 2

[0049] see Figure 7 , Figure 7 It is a schematic structural diagram of another embodiment of the reactor device for producing petroleum aids for oil drilling according to the present invention. The difference from Example 1 is that in Example 2, the reactor body 1 includes a first reactor body 15 and a second reactor body 16 , and the first reactor body 15 and the second reactor body 16 They are communicated through a material pipeline, and a valve 6 is arranged on the material pipeline. Further, the top of the second reactor body 16 is communicated with the third storage tank 8 through a material pipeline, and the third storage tank 8 is used to store materials to be added in the middle, so as to improve the utilization efficiency of the reactor device.

[0050] To sum up, the connecting rods are arranged around the rotating shaft, and the connecting rods adopt a layered design, which can effectively stir and mix the materials in the reactor body, and improve the work eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com