Polishing device for automobile parts

A technology for spare parts and automobiles, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., which can solve the problems of residue residue, impact on grinding effect, and poor friction, etc., to reduce waste residue and improve grinding effect, the effect of avoiding deformation or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

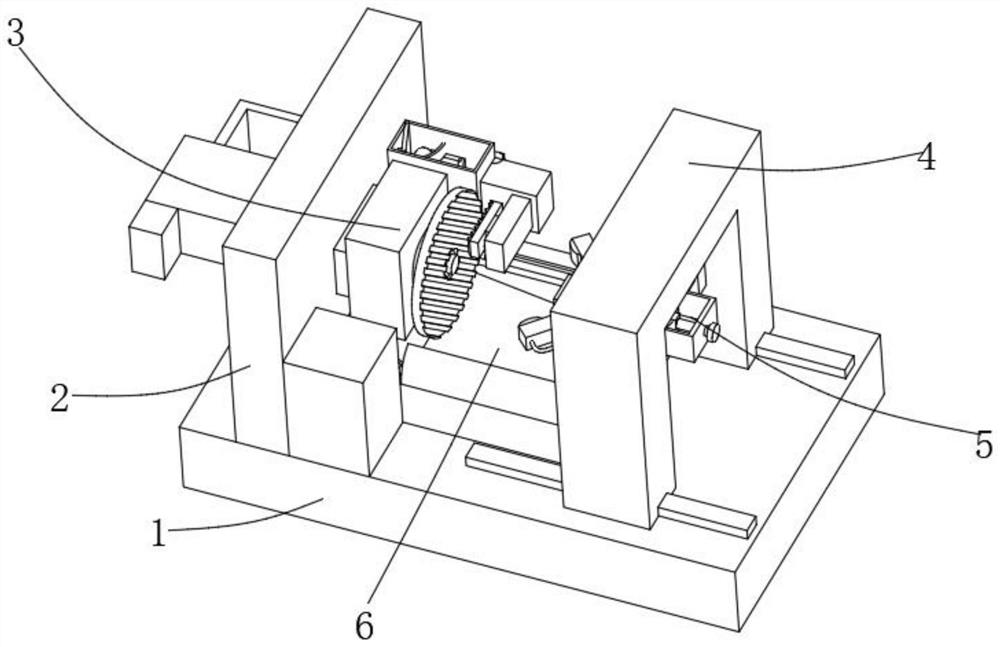

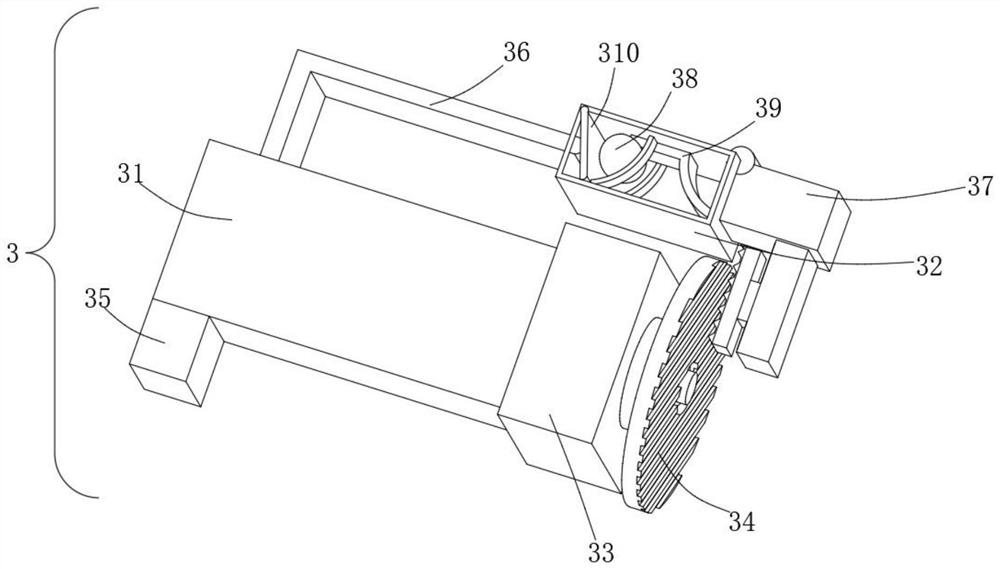

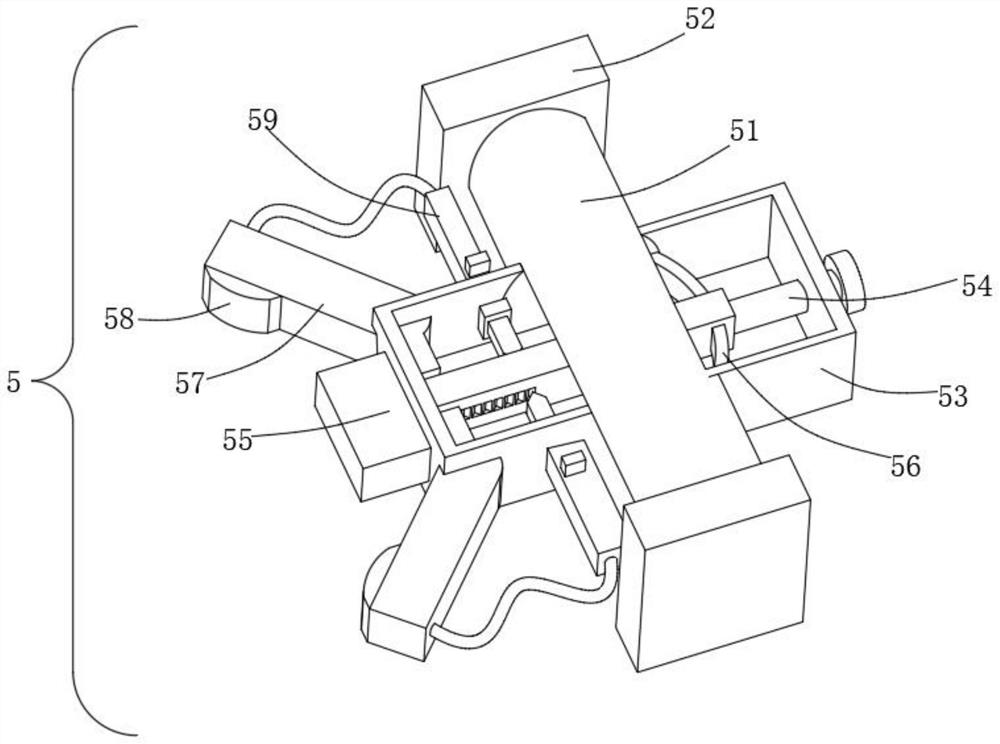

[0027] see Figure 1-6 , The present invention provides a technical solution: a grinding device for auto parts, comprising a base 1, an iron support plate 2 is fixed on the upper surface of the base 1, a grinding device 3 is arranged on the iron support plate 2, and the grinding device 3 It includes a sliding rod 31 and a housing one 32. A rotary motor 33 is fixed on the right side of the sliding rod 31. The output shaft of the rotary motor 33 is connected with a grinding wheel 34 through a nut. The front end of the sliding rod 31 is fixed with a strong magnet 35. The sliding rod The back of 31 is fixed with an L-shaped mandrel 36, the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com