Environment-friendly cement production line and production process thereof

A cement production device and production line technology, applied in cocoa, application, grain processing, etc., can solve problems such as easy jamming of the device, inability to sieve, and more dust, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

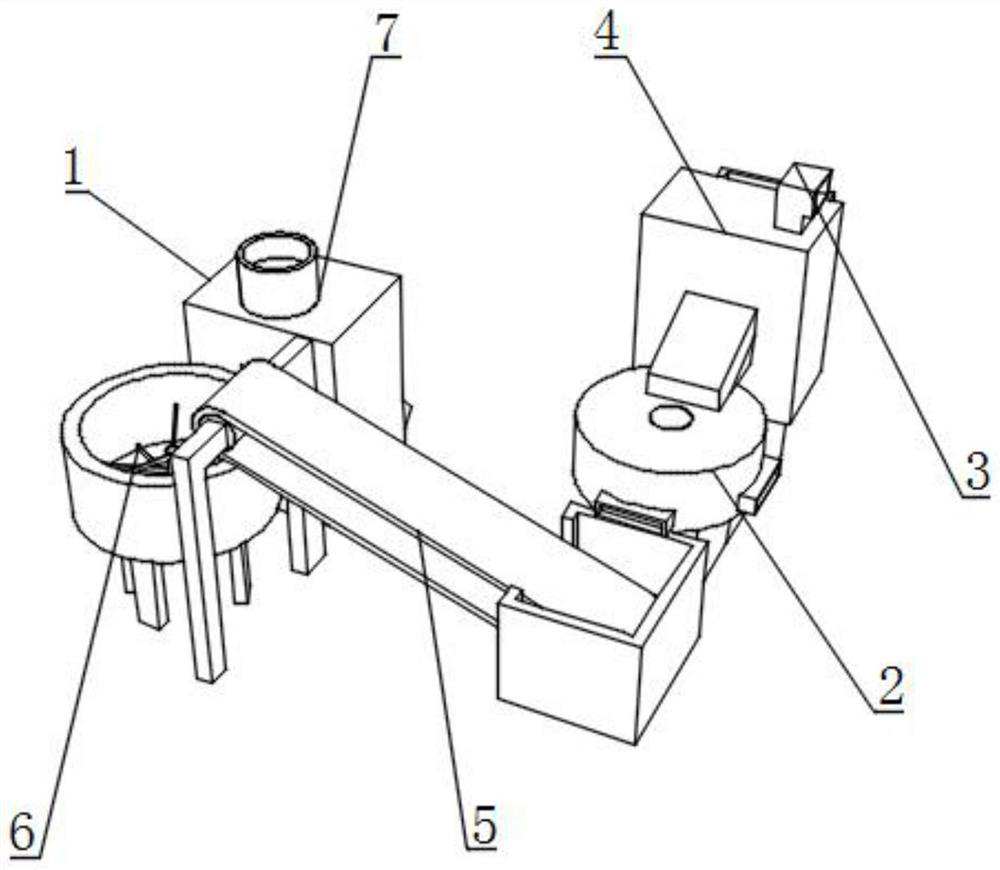

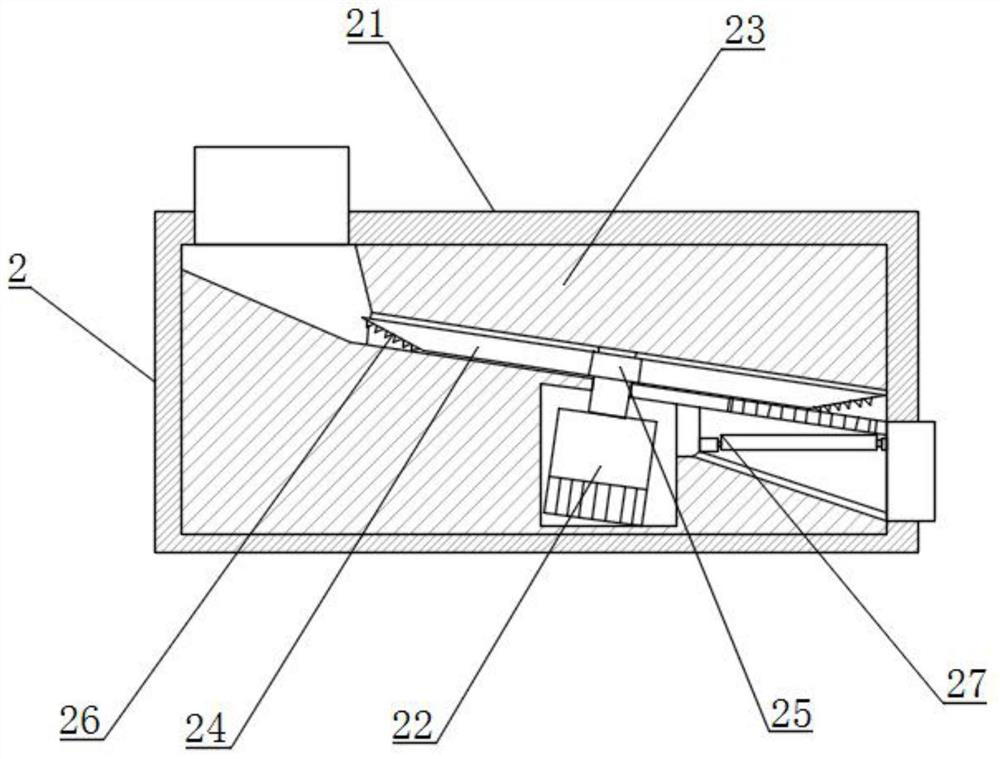

[0037] like Figure 1-7As shown, the present invention provides an environmentally friendly cement production line, a cement production device main body 1, the cement production device main body 1 includes a pulverizing device 4, one side of the pulverizing device 4 is provided with a conveyor belt 5, and one end of the conveyor belt 5 is provided with a stirring device 6. One side of the stirring device 6 is provided with a heating device 7, one side of the pulverizing device 4 is provided with a grinding device 2, and the interior of the grinding device 4 is provided with a dust removal device 3; The inner wall is fixedly connected with a baffle 23, the inner wall of the baffle 23 is fixedly connected with a motor one 22, one side of the motor one 22 is provided with an elastic device 25, a screening device 27, and the dust removal device 3 includes a ventilation pipe 31, and the inner wall of the ventilation pipe 31 is provided. A filter screen 39 is movably connected, a cu...

Embodiment 2

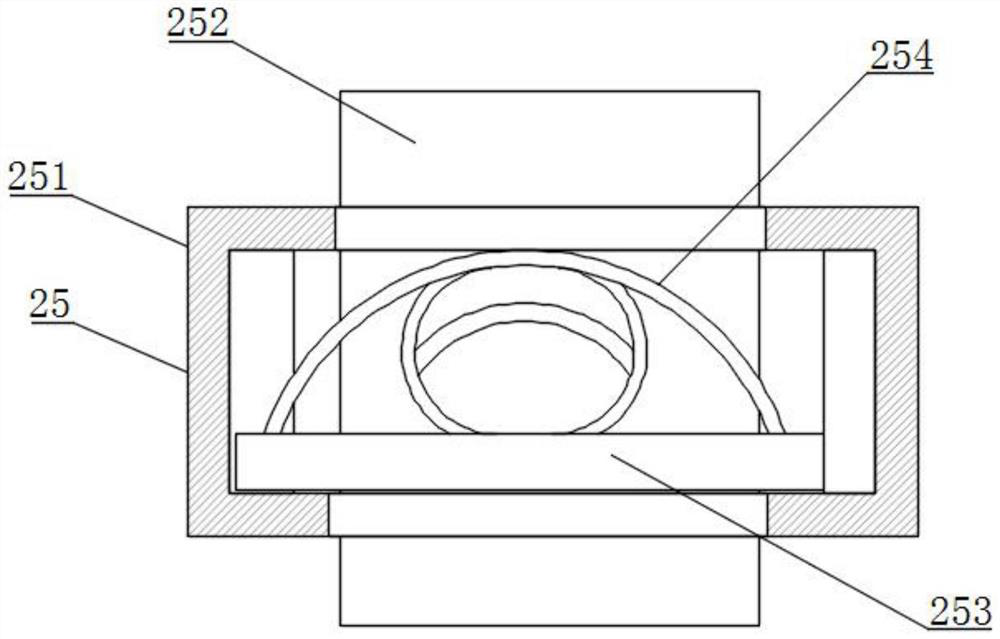

[0039] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the screening device 27 includes a fixed casing 1 271, the inner wall of the fixed casing 1 271 is fixedly connected with a second motor 272, and the output of the second motor 272 is fixed The shaft is fixedly connected with a protruding rod 273, the outer wall of the protruding rod 273 is movably connected with a filter disc 274, and the outer wall of the other end of the filter disc 274 is movably connected with a fixed housing two 275, and the outer wall of the fixed housing two 275 is fixedly connected with one side of the inner wall of the housing 21. , the inner wall of the second fixed shell 275 is fixedly connected with a fixed sliding rod 279, the outer wall of the fixed sliding rod 279 is movably connected with the inner wall of one end of the filter disc 274, the bottom inner wall of the second fixed shell 275 is fixedly connected with a f...

Embodiment 3

[0041] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a water storage tank 35 is fixedly connected to the outer wall of the ventilation pipe 31, and a water pump 34 is fixedly connected to the top inner wall of the water storage tank 35. The input of the water pump 34 The end is fixedly connected with a water suction pipe 36, the bottom inner wall of the water storage tank 35 is fixedly connected with a water filter screen 32, the inner wall of the water filter screen 32 is movably connected with the outer wall of the water suction pipe 36, and one side of the water absorption sponge 38 is connected with one side of the filter screen 39. Actively connected, the current limiting device 37 is arranged on the top of the water absorbing sponge 38, the air blowing device 33 is fixedly connected to one side of the inner wall of the ventilation pipe 31, the current limiting device 37 includes a water passing sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com