Low-density composite ceramic ball for fluidized bed as well as preparation method and application of low-density composite ceramic ball

A technology of composite ceramics and curing agent, applied in fluidized bed heat exchangers, lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as weak thermal shock resistance, uneven fluidization, and difficult circulation, and achieve High mechanical strength and corrosion resistance, uniform fluidization and distribution, and superior comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

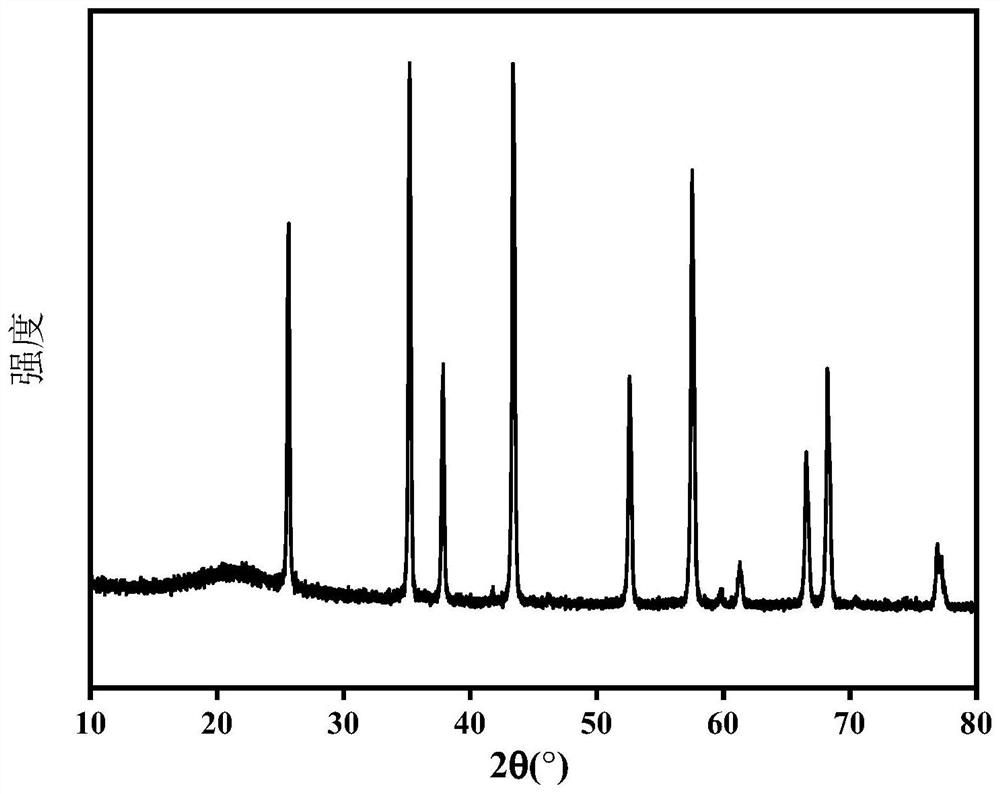

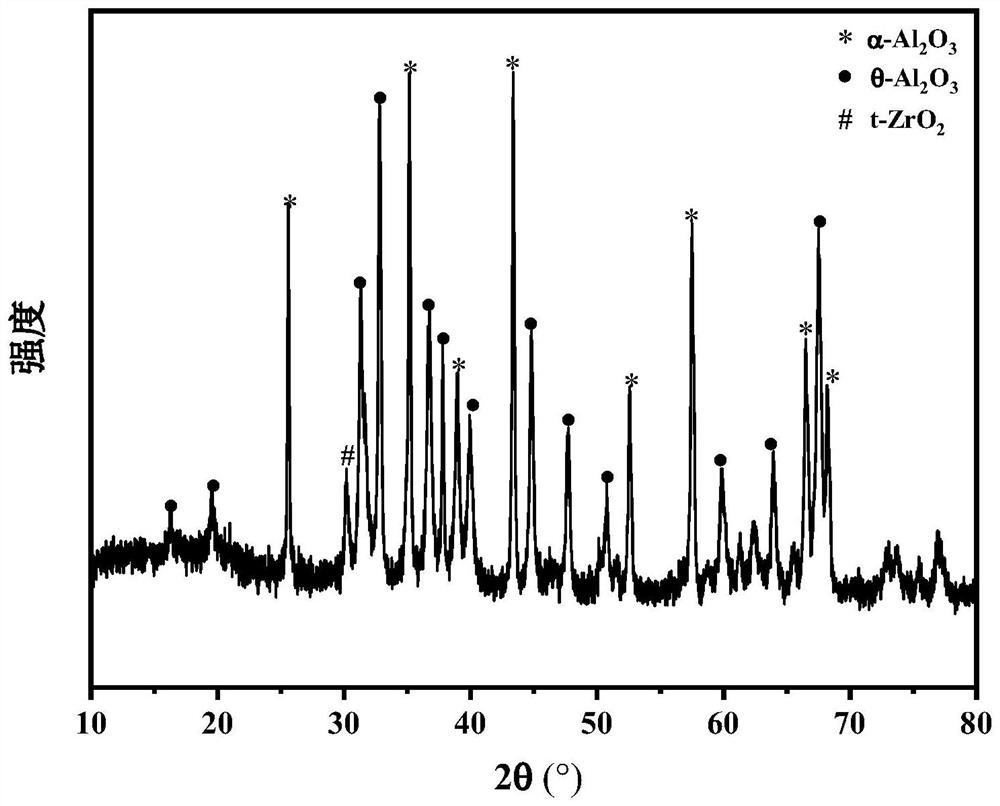

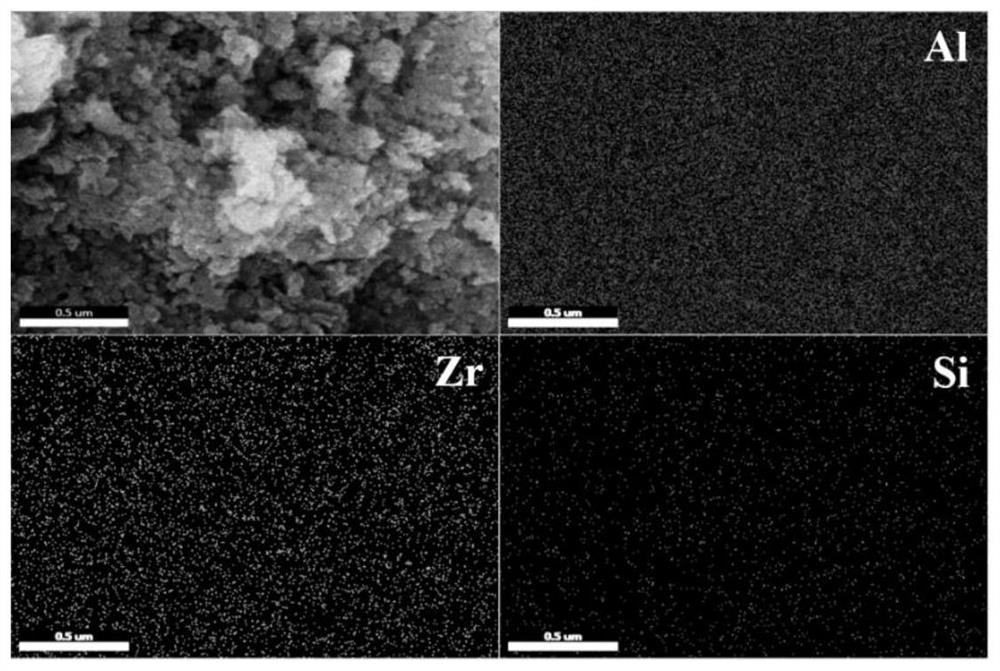

[0111] ZrO 2 / SiO 2 / Al 2 O 3 The preparation method of spherical composite ceramic ball is as follows:

[0112] (1) Weigh 16.5g of aluminum powder and 84mL of deionized water into a three-necked flask, and at the same time, stir vigorously to make it evenly dispersed in water in a constant temperature oil bath at 75°C for three minutes, at a rate of 8 drops per minute Drop into 58ml of 3mol / LAlCl 3 Solution (aluminum powder and AlCl 3 The molar ratio of 3.5) was reacted for 2 to 3 hours, and then the temperature of the oil bath was increased to 98 °C, and 5.25 ml of 2.5 mol / L ZrOCl was added at the same time. 2 The solution was slowly dropped into the flask, aluminum powder and AlCl 3 The sum of the molar amounts of ZrOCl 2 The molar ratio is 60:1, react with the remaining aluminum powder for 2 to 3 hours, then the mixture is stirred and reacted at 98 °C; finally, 4g of 20wt% silica sol (take 30wt% silicon The sol was diluted to 20 wt %, the same below), continuously ...

Embodiment 2

[0116] Spherical composite ceramic balls are prepared with reference to the method of Example 1, the difference is that in step (1), ZrOCl 2 The solution and the silica sol were added at the same time, specifically including: weighing 16.5 g of aluminum powder and 84 mL of deionized water into a three-necked flask, while vigorously stirring to make it evenly dispersed in water in a constant temperature oil bath at 75°C. After three minutes, drip 8ml of 3mol / L AlCl at a rate of 8 drops per minute 3 Solution (aluminum powder and AlCl 3 The molar ratio of 3.5) was reacted for 2 to 3 h; then the temperature of the oil bath was increased to 98 °C, and 5 ml of 2.5 mol / L ZrOCl was mixed at the same time. 2 The solution and 4 g of 20 wt % silica sol were slowly dropped into the flask and reacted at 98° C. for 10-12 h to obtain the silica-zirconium-alumina sol. The spherical composite particles obtained in this example, wherein the molar ratio of Zr, Si and Al is 1:1:60, which is den...

Embodiment 3

[0118] The spherical composite ceramic ball was prepared with reference to the method of Example 1, the difference was that in step (1), firstly adding silica sol to form a gel and then adding ZrOCl 2 The solution specifically includes: Weighing 16.5 g of aluminum powder and 84 mL of deionized water into a three-necked flask, while vigorously stirring to make it evenly dispersed in water in a constant temperature oil bath at 75°C. After three minutes, drop in 58ml of 3mol / L AlCl at a rate of 8 drops per minute 3 Solution (aluminum powder and AlCl 3 The molar ratio of 3.5) was reacted for 2 to 3 hours; then the temperature of the oil bath was increased to 98°C, and 4g of 20wt% silica sol was slowly dropped into the flask, aluminum powder and AlCl 3 The molar ratio of the sum of the molar amounts of ZrOCl to the silica sol was 60:1, and then the mixture was continuously stirred and reacted at 98 °C for 2 to 3 h; finally, 2.5 mol / L ZrOCl was added dropwise to the reactor. 2 Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com