ABS (Acrylonitrile Butadiene Styrene) composite material with high gloss and high flickering effect and preparation method thereof

A composite material and high-gloss technology, which is applied in the fields of automobiles, general-purpose resins, and home appliances, can solve problems such as matching without consideration, and achieve the effects of avoiding environmental risks, reducing weld lines, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

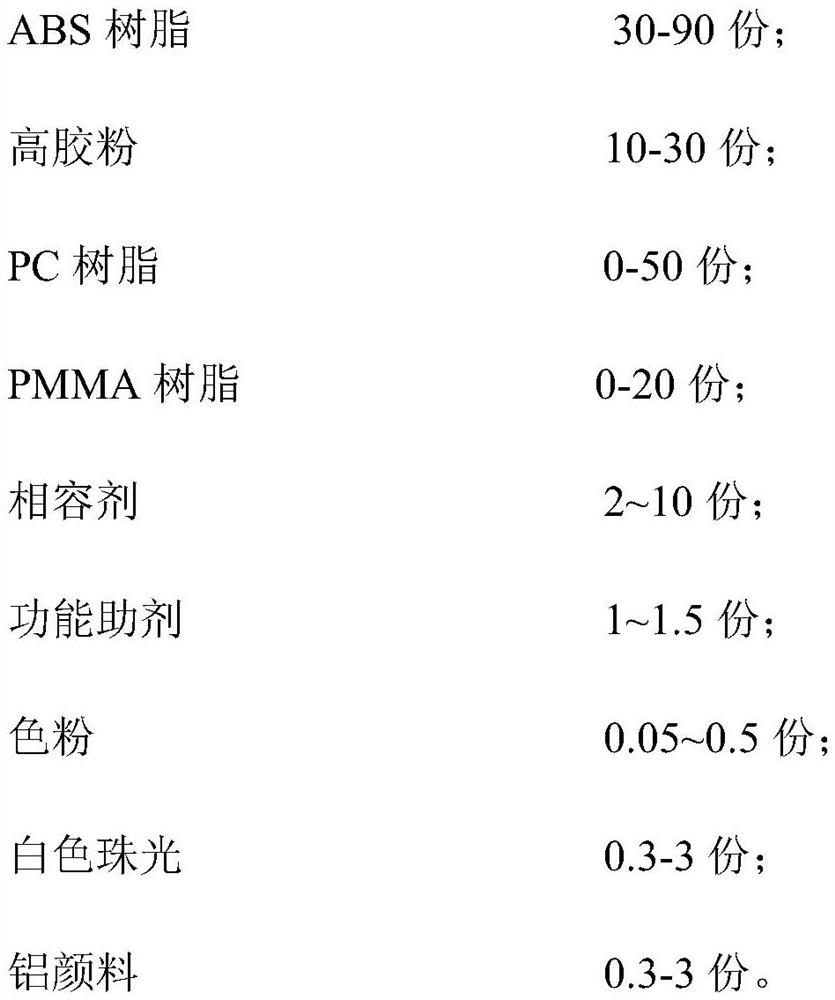

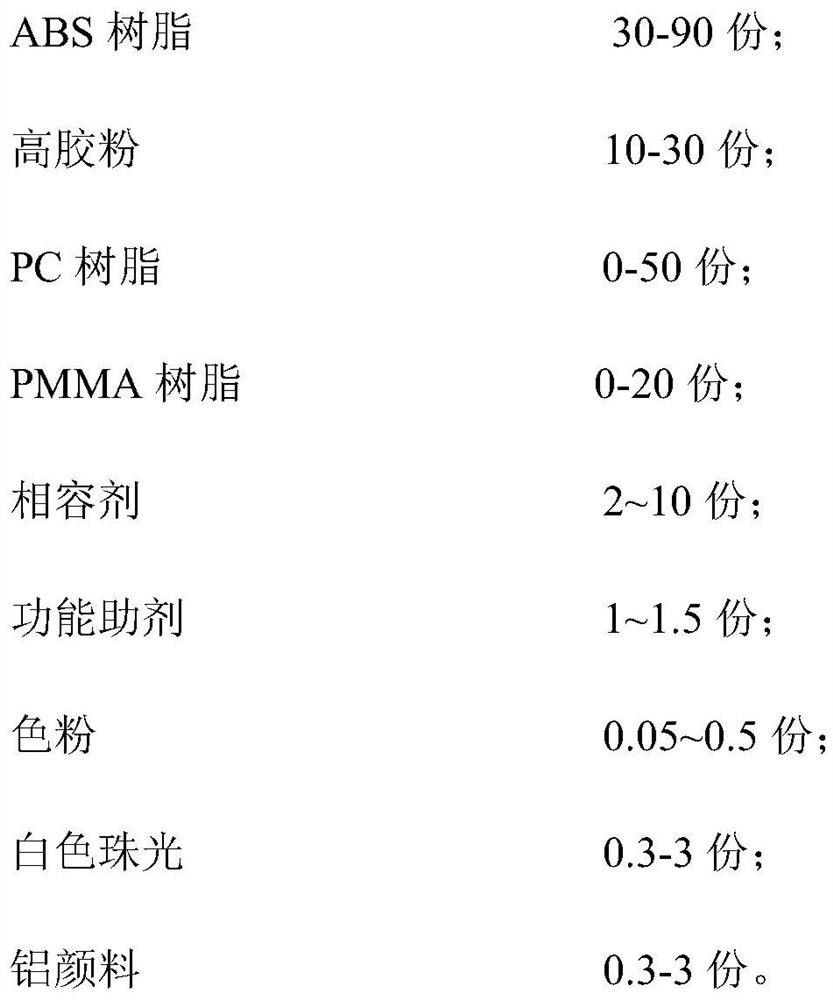

Method used

Image

Examples

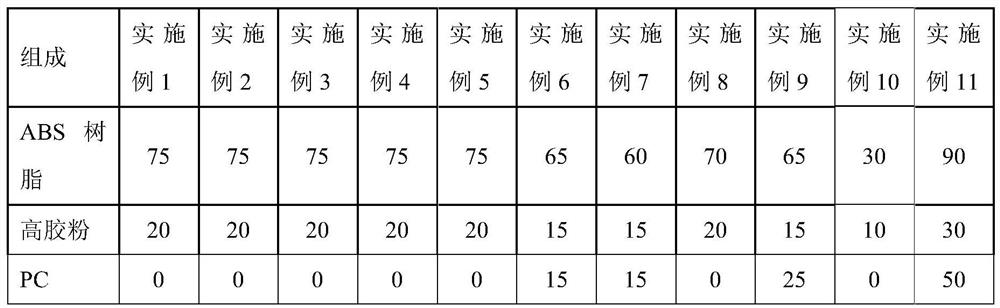

Embodiment 1~8 and comparative example l~8

[0040] According to the composition formula (parts by weight) in Table 1, ABS resin, high rubber powder, PC resin, PMMA resin, compatibilizer, antioxidant, light stabilizer, lubricant and toner were mixed and added from the main feeding port. To the twin-screw extruder, mix the white pearlescent and aluminum pigments and add it to the twin-screw extruder from the side feed port (screw diameter is 35mm, length-diameter ratio L / D=40, and the side feed port is located at the fifth heating port. segment) in the screw barrel. The control temperature of each section of the screw barrel (from the feeding port to the head outlet) is 120°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C, 245°C, and the speed of the twin-screw At 450 rpm, the extruded strips are cooled in a water tank and then cut into pellets to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com