Treatment system for poisoning of wet desulphurization slurry

A treatment system, wet desulfurization technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of increased concentration of sulfur dioxide in net flue gas, uncontrollable pH value of slurry, insufficient oxidation, etc., to achieve saving Waste of limestone discharge, increase comprehensive utilization value, and reduce the effect of starting the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

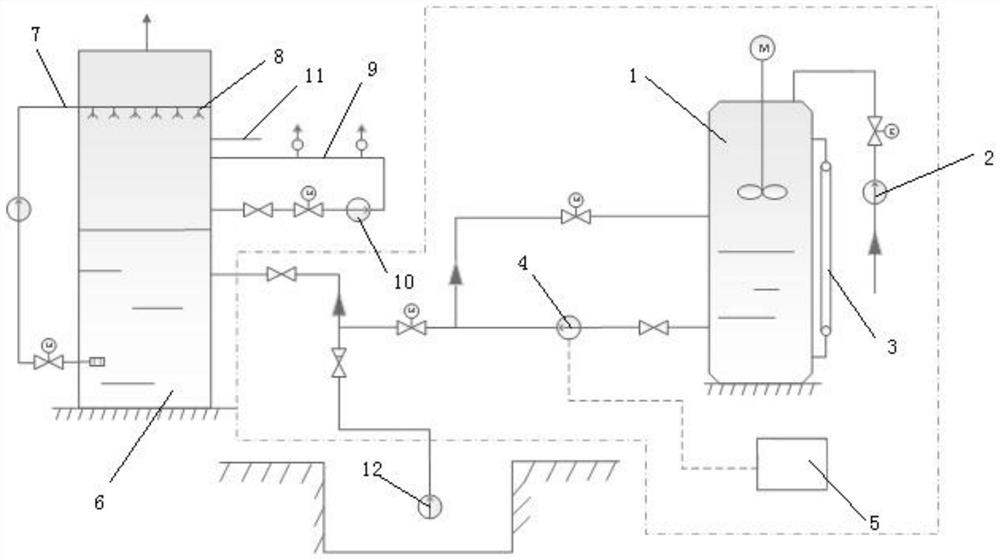

[0020] Such as figure 1 As shown, the present invention provides a wet desulfurization slurry poisoning treatment system, including a desulfurization absorption tower 6, an air inlet pipe 11 is arranged on the side wall of the desulfurization absorption tower 6, and a spray head 8 is arranged inside the desulfurization absorption tower 6, The side wall of the desulfurization absorption tower 6 is provided with a first circulation line 7, one end of the first circulation line 7 is connected to the bottom of the desulfurization absorption tower 6, and the other end of the first circulation line 7 is connected to the The spray head 7 is connected, so that the absorption liquid can circulate and spray and absorb the internal flue gas through the first circulation pipeline 7. The side wall of the desulfurization absorption tower 6 is provided with an absorption liquid addition pipeline, and the absorption liquid is added to A liquid addition pump 12 is arranged on the pipeline, and...

Embodiment 2

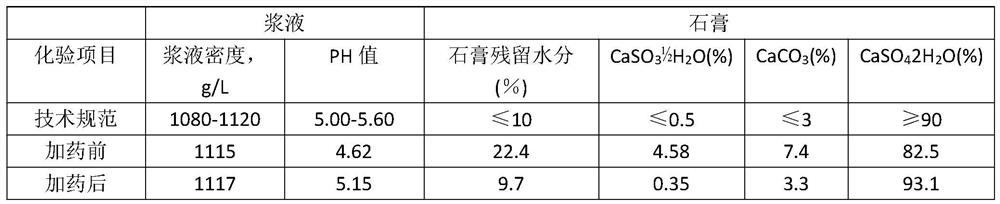

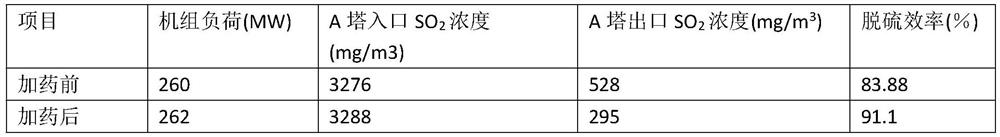

[0022] Most of the generating units in large coal-fired power plants use wet desulfurization. The flue gas after boiler combustion is denitrified and dust-removed and then enters the desulfurization absorption tower. In the tower, the flue gas and sprayed limestone slurry are used for mass transfer and heat transfer, and chemical reactions occur. , that is, calcium carbonate and sulfur dioxide react chemically to form calcium sulfite or calcium sulfate to remove sulfur dioxide in the flue gas. The indicators monitored during operation include: desulfurization efficiency, net flue gas sulfur dioxide concentration, slurry pH value and slurry density etc., the slurry is extracted from the absorption tower by the measuring pump 10, and returned to the absorption tower after the data are measured by the pH meter and the density meter. The data of desulfurization efficiency and net flue gas sulfur dioxide concentration are output by other measurement modules (not shown in the figure)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com