Texturing additive, texturing liquid and preparation method and application of texturing additive and texturing liquid

A technology of additives and texturing liquid, applied in chemical instruments and methods, post-processing details, polycrystalline material growth, etc., can solve the problems of small specific surface area, poor light trapping effect, short optical path, etc. The effect of stable surface structure, low cost of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

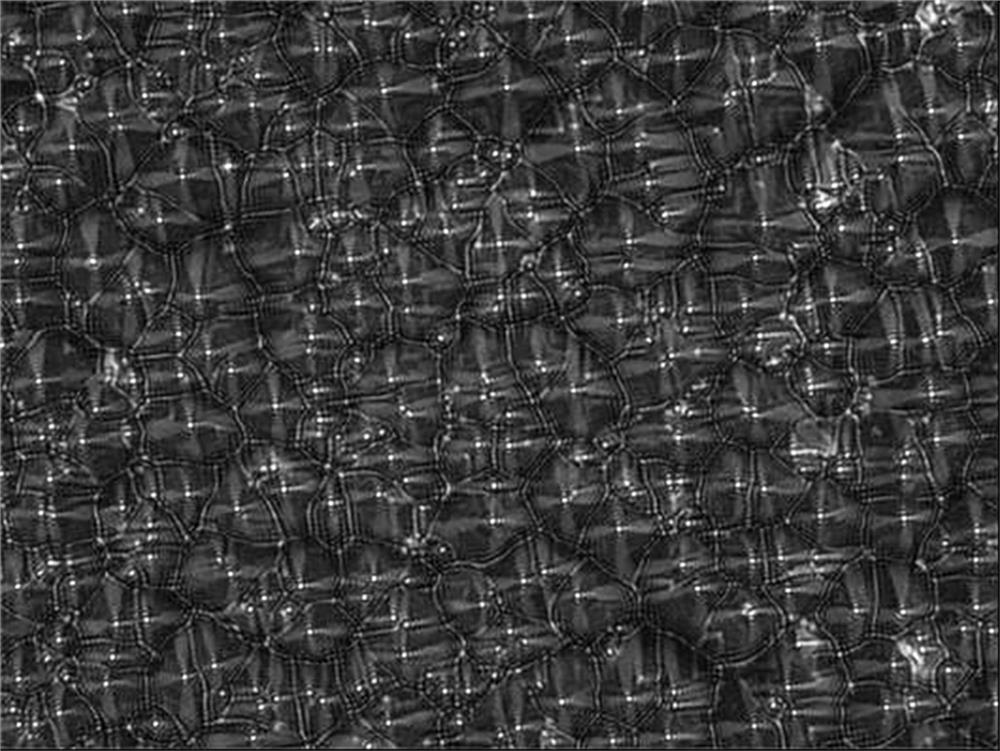

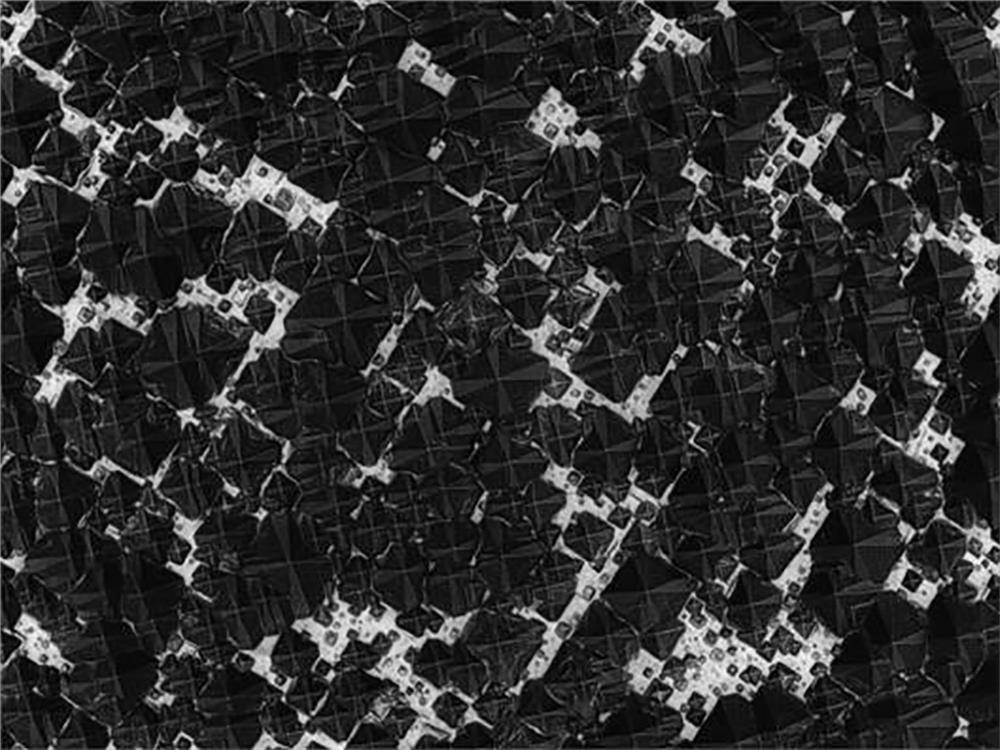

Image

Examples

Embodiment 1

[0048] A texturing additive comprises 1 wt % of sodium dodecyl sulfonate, 0.5 wt % of nonionic polyacrylamide with a molecular weight of 5-10 million, 1.5 wt % of alkylphenol polyoxyethylene ether, and the balance is water.

Embodiment 2

[0050] A texturing additive comprises 2 wt % of sodium dodecyl sulfonate, 0.5 wt % of nonionic polyacrylamide with a molecular weight of 5-10 million, 1.5 wt % of alkylphenol polyoxyethylene ether, and the balance is water.

Embodiment 3

[0052] A texturing additive comprises 3 wt % of sodium dodecyl sulfonate, 0.5 wt % of nonionic polyacrylamide with a molecular weight of 5-10 million, 1.5 wt % of alkylphenol polyoxyethylene ether, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com