TA2 pure titanium color metallographic corrosion method convenient to identify

A color metallographic and pure titanium technology, applied in the preparation of test samples, instruments, measuring devices, etc., to achieve the effects of convenient operation, clear grain combination characteristics, and good metallographic display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

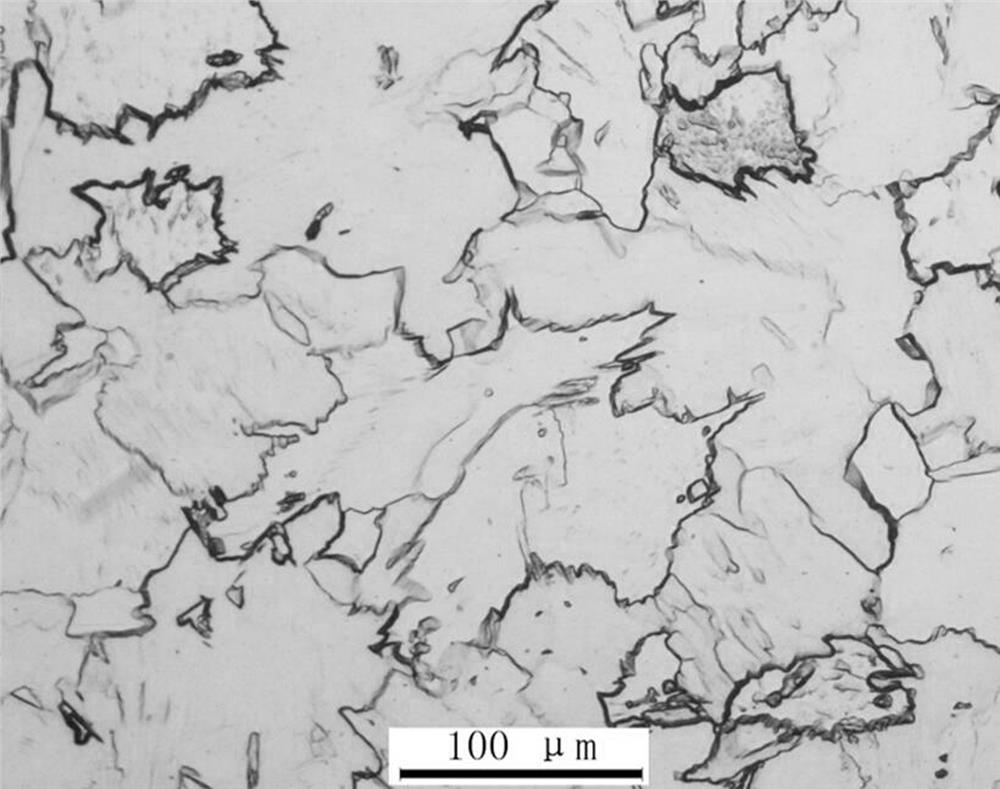

[0045] A convenient identification type color metallographic corrosion method for TA2 pure titanium, the present embodiment uses as-cast TA2 pure titanium as the metallographic sample, and specifically includes the following steps:

[0046] 1) Prepare a corrosive agent, measure 100ml of water and pour it into a plastic container, then measure 18g of ammonium bifluoride and pour it into the solution, stir well and use at room temperature;

[0047] 2) Take the TA2 pure titanium metallographic sample, and perform rough grinding, fine grinding, polishing, cleaning and drying on the surface in turn to obtain a clean, bright and scratch-free sample to be tested;

[0048] 3) Use plastic tweezers to hold the absorbent cotton, dip the corrosive agent prepared above, and wipe the surface of the sample. After 40 seconds, the surface of the sample is observed to be dark brown;

[0049] 4) Rinse the sample with running water, rinse the sample with absolute ethanol, dry it with a hair dryer...

Embodiment 2

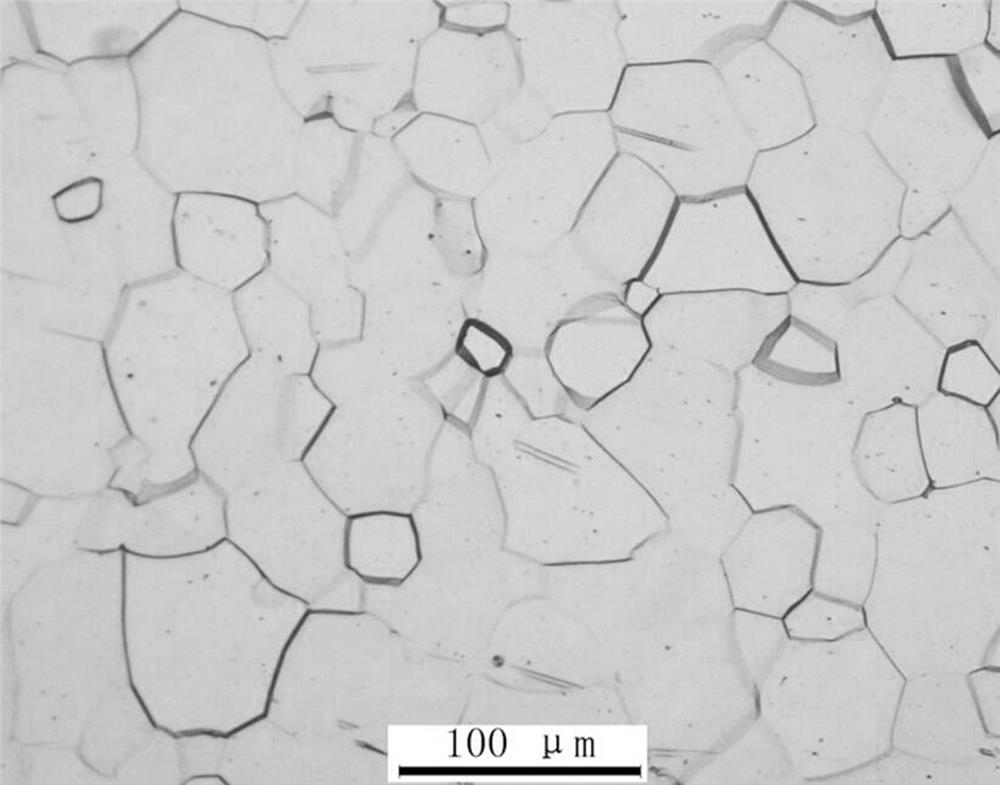

[0052] In this example, TA2 pure titanium in rolling and annealing state is used as the metallographic sample, and the rest of the operation steps are the same as those in Example 1.

[0053] The photo of the metallographic structure of this embodiment is attached Figure 4 shown, attached by Figure 4 It can be seen that the metallographic structure of the rolled and annealed TA2 pure titanium can be observed with color metallographic characteristics under the optical metallographic microscope. The metallographic structure of the rolled and annealed TA2 pure titanium is equiaxed α phase, equiaxed The grains show different color contrast, the grain shape is clear and intuitive, the color contrast is good, the grain boundary is not corroded, and the corrosion effect is excellent.

Embodiment 3

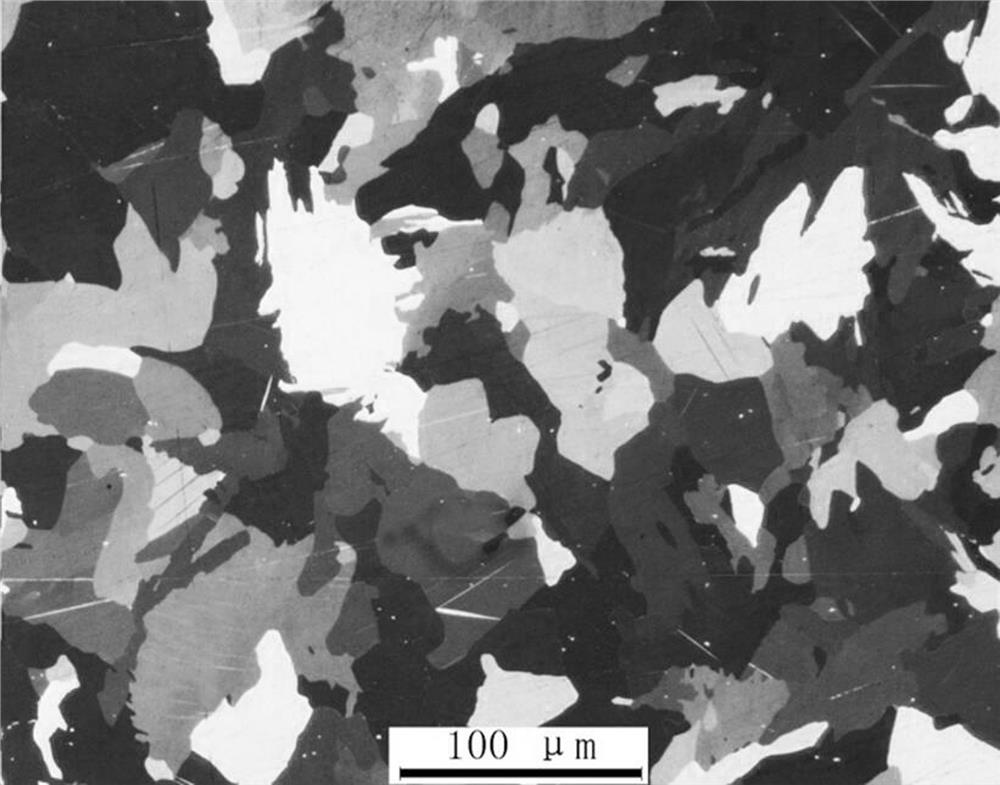

[0055] A convenient identification type color metallographic corrosion method for TA2 pure titanium, the present embodiment uses as-cast TA2 pure titanium as the metallographic sample, and specifically includes the following steps:

[0056] 1) Prepare a corrosive agent, measure 100ml of water and pour it into a plastic container, then measure 22g of ammonium bifluoride and pour it into the solution, stir well and use at room temperature;

[0057] 2) Take the TA2 pure titanium metallographic sample, and perform rough grinding, fine grinding, polishing, cleaning and drying on the surface in turn to obtain a clean, bright and scratch-free sample to be tested;

[0058] 3) Use plastic tweezers to hold the absorbent cotton, dip the corrosive agent prepared above, and wipe the surface of the sample. After 30 seconds, the surface of the sample is observed to be dark brown;

[0059] 4) Rinse the sample with running water, rinse the sample with absolute ethanol, dry it with a hair dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com