Photovoltaic module

A photovoltaic module and adhesive film technology, which is applied in the field of solar cells, can solve problems such as poor performance of photovoltaic modules, affecting the light absorption capacity of cells, and affecting the reflection ability of adhesive films, so as to achieve good absorption capacity, improve performance, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

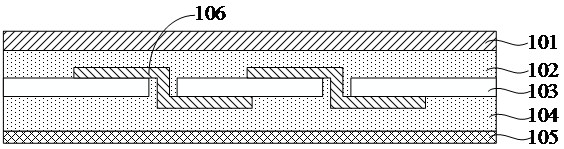

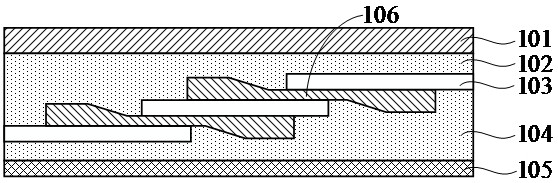

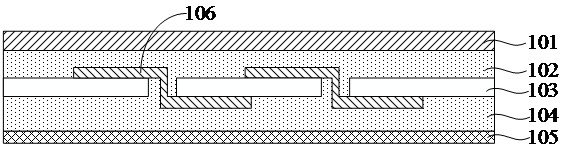

[0023] An embodiment of the present application provides a photovoltaic module, including: a first cover plate, a first adhesive film, a cell sheet, a second adhesive film and a second cover sheet, the thickness of the cell sheet being 100 μm to 170 μm, and the first adhesive film Under the condition that the thickness of the film is 300μm~550μm and the thickness of the second film is 300μm~710μm, the thickness of the first film and the thickness of the second film satisfy the following relationship: 0.0007x 2 -0.4297x+374.2≤y≤0.0034x 2 -1.0297x+314.19, where x is the thickness of the first adhesive film, and y is the thickness of the second adhesive film. In this way, the thickness of the first adhesive film and the thickness of the second adhesive film can be matched with the battery sheet respectively, so that The first film and the second film have a strong ability to absorb incident light, improve the absorption and utilization rate of the cell to the incident light, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap