Solid wood floor surface transverse sand processing technology and manufacturing equipment thereof

A solid wood floor, processing and manufacturing technology, applied in metal processing equipment, wood processing appliances, manufacturing tools, etc., can solve problems such as damage to devices and boards, waste of resources, and reduced working life of devices, and achieve easy use, convenient conversion, and reduced The effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

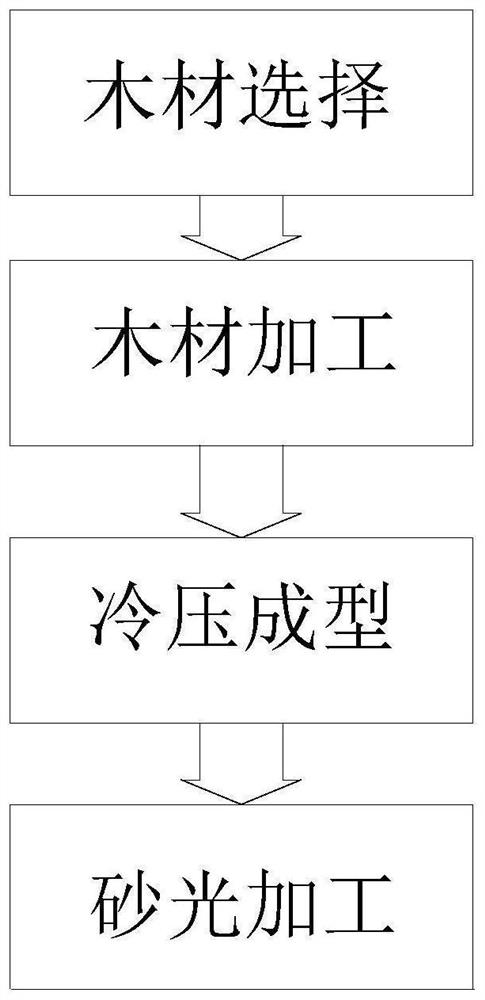

[0033] like Figure 1-6 As shown in the figure, the present invention provides a process for processing the surface of solid wood floor with horizontal sand and its manufacturing equipment. Step 1: wood selection, first select suitable wood, which can be dried in a drying kiln, so as to avoid more moisture in the wood, resulting in The inconvenience of processing will cause corrosion damage to the wood. While drying, the water stains can be absorbed by a water-absorbing sponge on the outside of the wood, and then dried by a drying kiln;

[0034] Step 2: wood processing, secondly, the dried wood is preferably cut off, and the high-quality part is extracted and produced separately, and then the wood board is put into the interior of the planing device, so that the outside of the wood can be planed;

[0035] Step 3: Cold-press forming, then apply glue on the outside of the wood, and use the roller shaft to roll on the outside of the wood. Apply glue to the outside of the wood, a...

Embodiment 2

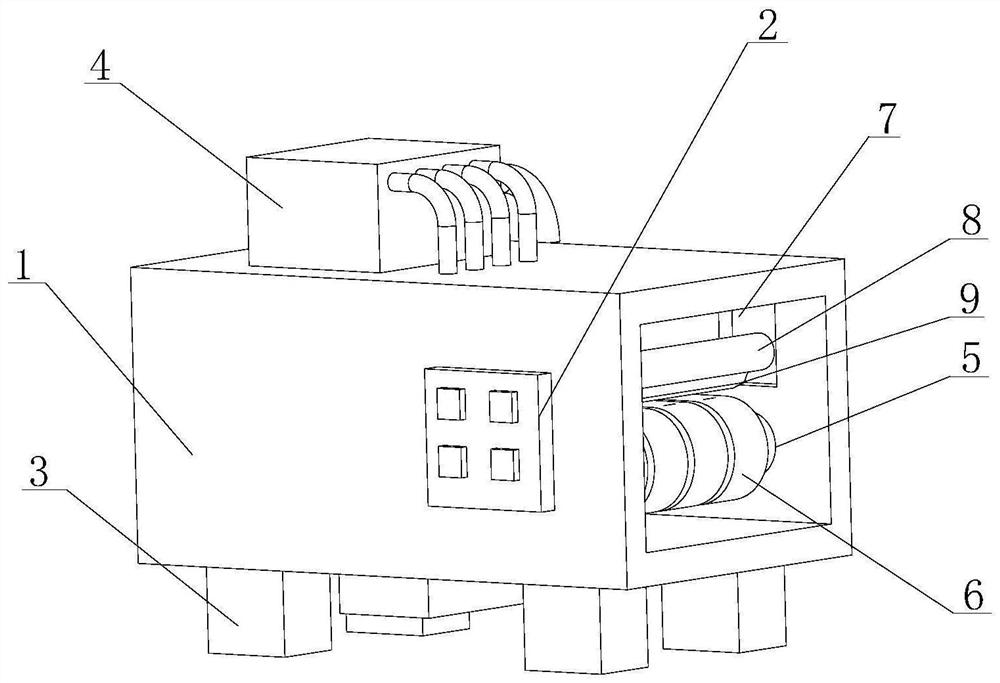

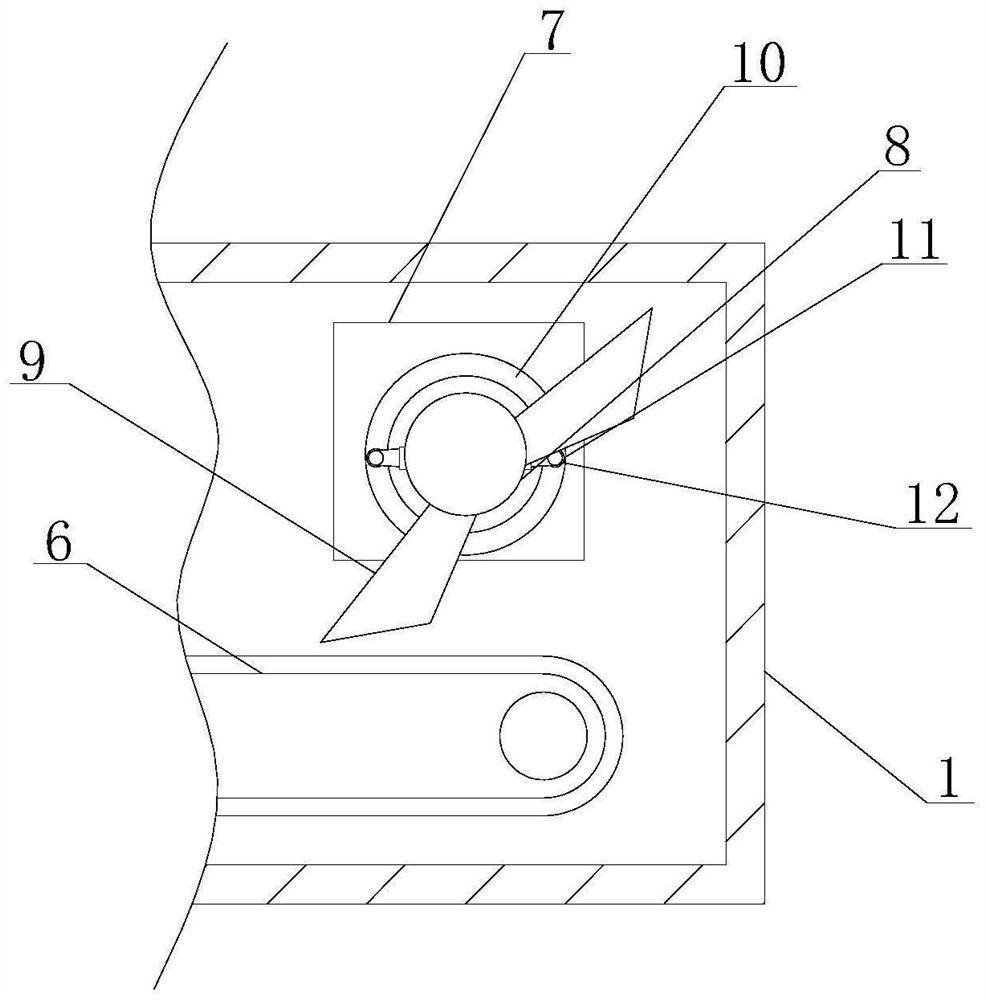

[0038] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a solid wood floor surface horizontal sand processing and manufacturing equipment, including a processing equipment main body 1, the lower end of the processing equipment main body 1 is fixedly connected with a shock-absorbing support Leg 3, a movable shaft 5 is arranged inside the main body 1 of the processing equipment, and a transmission mesh belt 6 is arranged outside the movable shaft 5. The combination of the processing equipment main body 1, the movable shaft 5, the transmission mesh belt 6 and the fixed baffle 20 can The transmission of the wooden board is fixed to avoid the phenomenon of deviation during the transmission process, which causes inconvenience in the processing of the wooden board, and at the same time causes damage to the device and reduces the service life of the device. The inside of the groove 7 is movably connected with the...

Embodiment 3

[0041] like Figure 1-6 As shown, on the basis of Embodiments 1 and 2, the present invention provides a technical solution: preferably, the control element 2 is fixedly connected to the front of the processing equipment main body 1, and the processing liquid tank 4 is fixedly connected to the upper end of the processing equipment main body 1. A connecting shaft 14 is movably connected inside the limiting module 13 , the upper end of the connecting rod 16 is fixedly connected with a limiting fixing spring 15 , and the upper end of the limiting fixing spring 15 is fixedly connected with the inner top of the limiting module 13 .

[0042] The interior of the fixed module 12 is provided with a groove 17, the upper end of the sliding module 19 is fixedly connected with a shock-absorbing spring 18, and the upper end of the shock-absorbing spring 18 is fixedly connected with the inner top end of the groove 17.

[0043] The outside of the sliding module 19 is provided with a limiting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com