Volatile organic waste gas separation device

A volatile organic and separation device technology, applied in water aeration, water/sewage multi-stage treatment, contaminated groundwater/leachate treatment, etc., can solve the problem of high cost of replacement materials for separation materials and single types of volatile pollutants and other issues, to achieve the effect of promoting sustainable development, beneficial to ecological environment protection, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

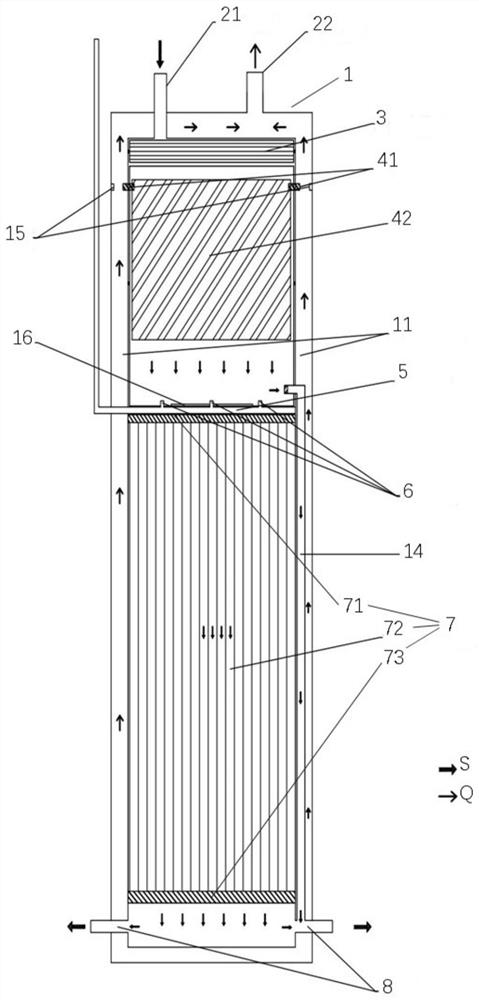

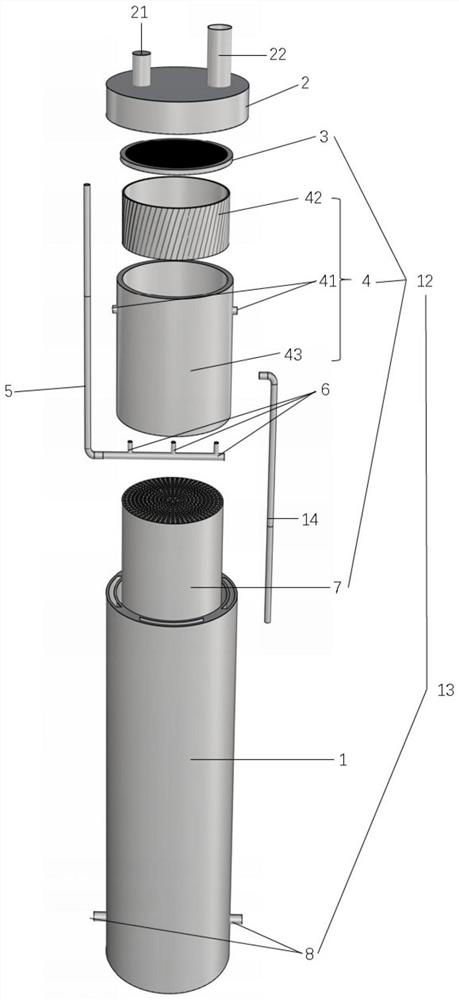

[0052] The present invention provides a volatile organic waste gas separation device, comprising a ventilation casing 1 with a double-layer outer wall structure, and a gap chamber capable of accommodating the circulation of organic waste gas is defined between the double-layer outer walls of the ventilation casing 1 . According to the invention, the directional exhaust of the organic waste gas is limited by the provision of a gas flow chamber 11 in the gap chamber, wherein the ventilation casing 1 is provided in its axial direction with a space capable of accommodating the separation unit 12 and is surrounded by the gas flow chamber 11 . The hollow inner cavity 13 is axially configured as a multi-level structure to accommodate the multiple components 3, 4, 7 of the separation unit 12, wherein the separation unit 12 is capable of extracting the multiphase entering the vent casing 1. It is arranged in the ventilating casing 1 in such a way that the organic waste gas in the volati...

Embodiment 2

[0081] The present invention also provides a method for separating volatile organic waste gas, the separation method comprising: selectively operating one or more components in the separation unit 12 to soften and pre-soften the multiphase extracting liquid entering the separation unit 12 through the ventilation shell 1 At least one of treatment, heating aeration and secondary separation, and directional separation of organic waste gas in the multi-phase extraction liquid in various paths, the separation unit 12 is used to detect the temperature of the multi-phase extraction liquid and the concentration of organic waste gas. way to control the selective operation of multiple components and the aeration amount of aeration to adjust the temperature of the multiphase extraction liquid.

[0082] according to figure 1 , figure 2 , the liquid flow direction S of the separated multiphase extracting solution of the present invention and the gas flow direction Q of the organic waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com