Semiconductor process chamber

A process chamber and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problems of reducing the stability of the machine, increasing the heat dissipation burden of the machine, and low efficiency of radio frequency power utilization. Heat generation, improved stability and reliability, and reduced ohmic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

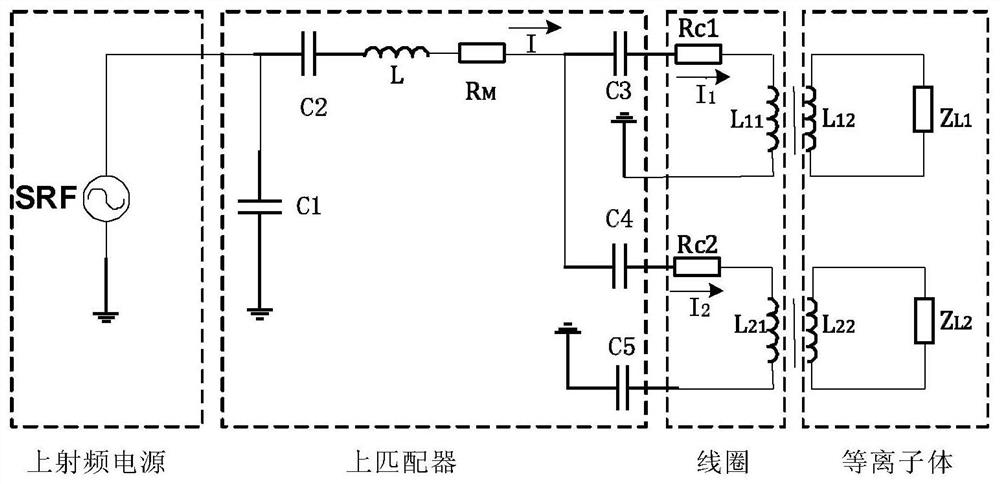

[0030] The equivalent circuit of the RF circuit of the upper electrode in the existing inductively coupled plasma device is as follows: figure 1 As shown, the upper RF power source (Source Generator) loads power to the coil (Coil) of the upper electrode through the upper matcher (Source Match), and the RF energy on the coil is coupled into the chamber through the dielectric window, thereby exciting the chamber. The process gas generates plasma, which acts on the wafer and can be used in processes such as wafer etching and deposition.

[0031] For the upper electrode RF circuit, the power of the upper RF power supply is mainly consumed by the loss power of the matcher, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com