Composite material air filter screen device with antibacterial and deodorizing functions

A composite material and air filter technology, used in deodorization, transportation and packaging, dispersed particle filtration, etc., can solve the problems of inability to remove bacteria and odors, lack of antibacterial and deodorization functions, and adverse health, and achieve improved use. Efficiency, increase the contact area, improve the effect of deodorization and deodorization efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

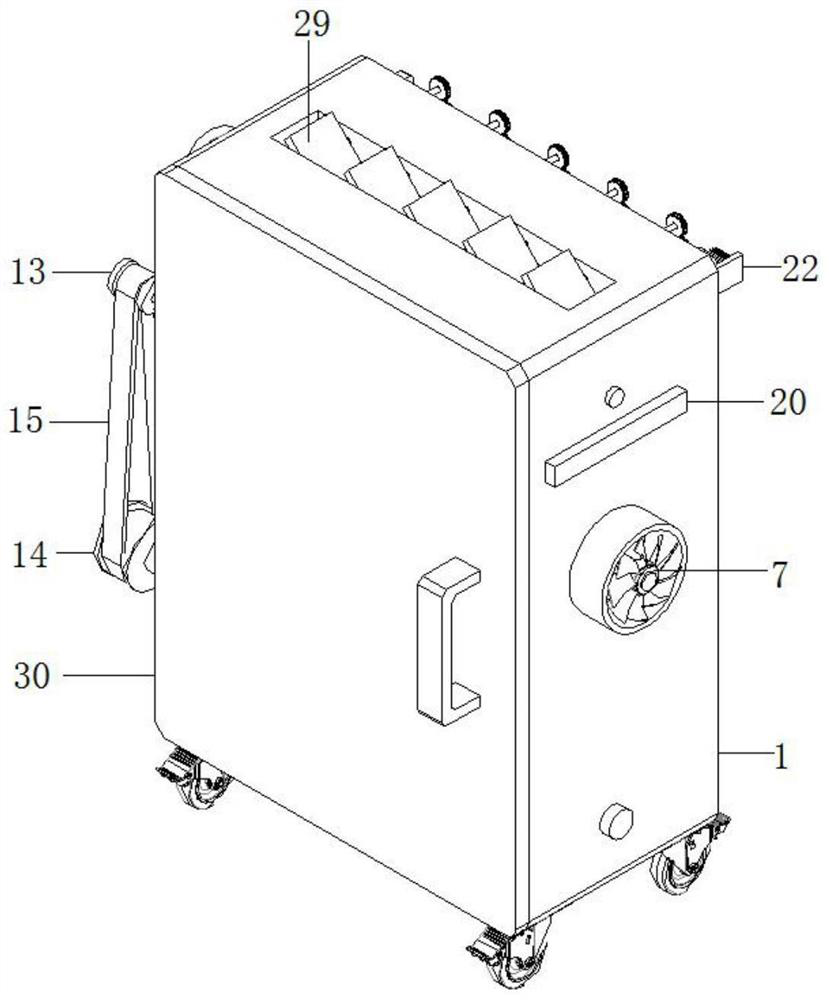

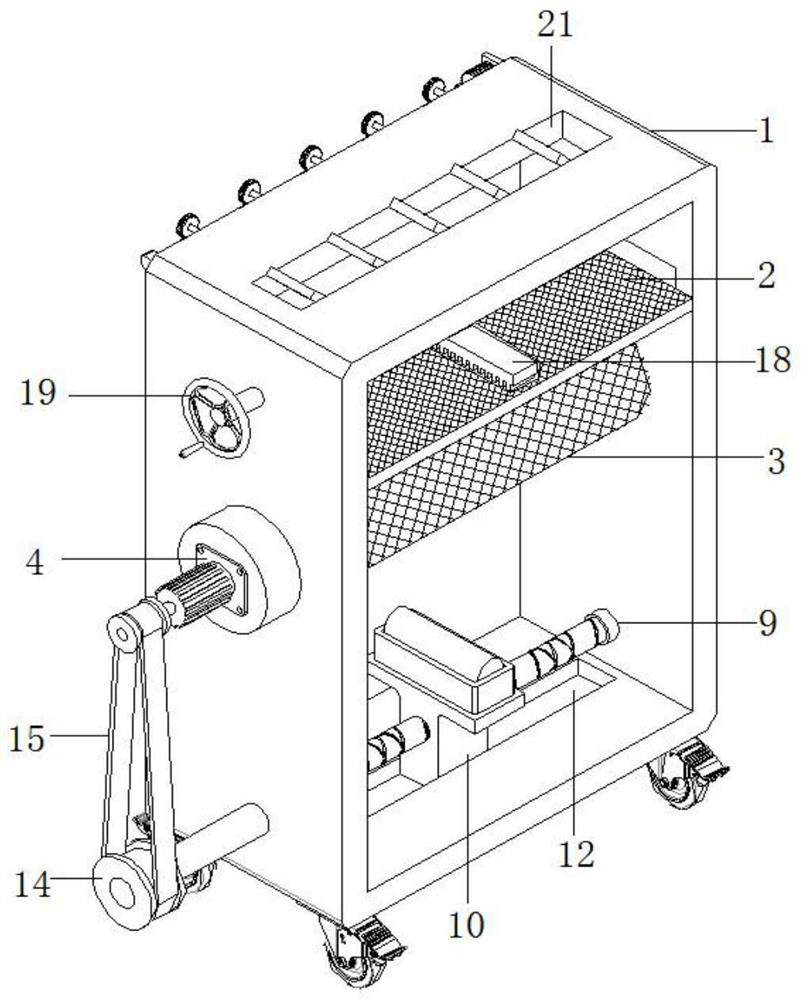

[0031] Example 1, refer to Figure 1-3 , a composite material air filter device with antibacterial and deodorizing function, comprising a casing 1, a composite material filter screen 2 and a deodorizing mechanism;

[0032] The composite material filter screen 2 is connected to the inner walls of the upper two sides of the casing 1 by bolts, the front of the casing 1 is hinged with a sealing door 30, and the front outer wall of the sealing door 30 is welded with a door handle. , double shaft motor 4, transmission rod 5, activated carbon filter 6, exhaust fan blade 7 and spiral stirring blade 8;

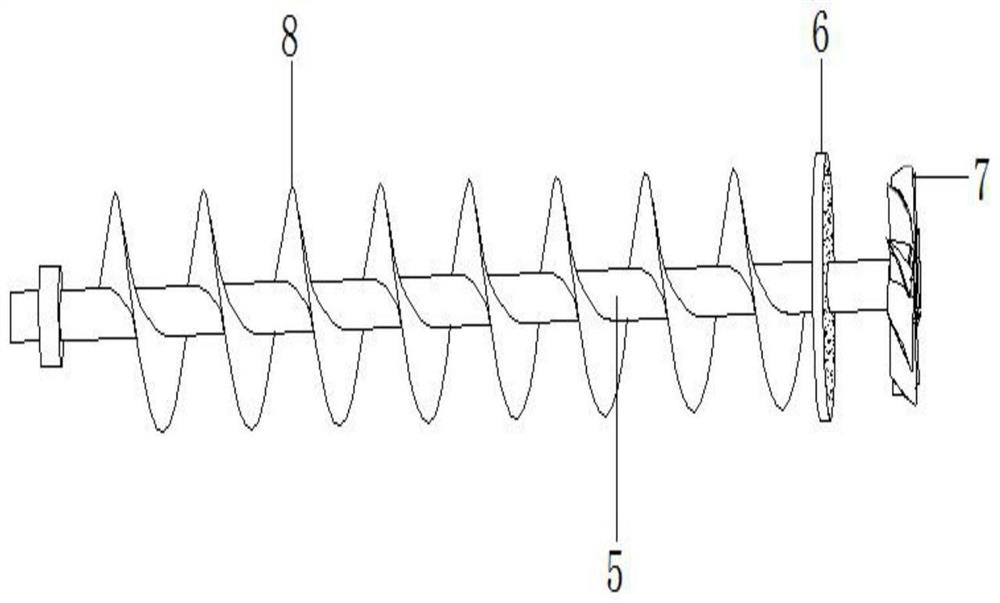

[0033] The air-permeable mesh cylinder 3 is fixed through the middle of the housing 1, the part of the air-permeable mesh cylinder 3 in the housing 1 is a permeable porous structure, the biaxial motor 4 is connected to the side wall of the air-permeable mesh cylinder 3 by bolts, and the first part of the biaxial motor 4 is An output shaft is connected through the inner wall of one sid...

Embodiment 2

[0036] Example 2, refer to figure 2 and Figure 4 , This embodiment is optimized on the basis of Embodiment 1, specifically: a composite material air filter device with antibacterial and deodorizing function, which also includes a sterilization mechanism and a transmission mechanism;

[0037] The sterilization mechanism is specifically composed of a reciprocating screw 9, a T-shaped slider 10, an ultraviolet sterilization lamp 11 and a limit groove 12, and the transmission mechanism is specifically composed of a driving pulley 13, a driven pulley 14 and an O-belt 15;

[0038] The reciprocating screw 9 is respectively connected to the inner walls of the lower part of the casing 1 through two sealed bearings, the T-shaped slider 10 is arranged in the middle of the reciprocating screw 9, and the ultraviolet germicidal lamp 11 is connected to the T-shaped slider 10 through bolts. On the top outer wall, the limiting groove 12 is opened on the bottom inner wall of the housing 1, a...

Embodiment 3

[0041] Example 3, refer to figure 2 and Figure 5 , This embodiment is optimized on the basis of Embodiment 1, specifically: a composite material air filter device with antibacterial and deodorizing function, which also includes a cleaning mechanism;

[0042] The cleaning mechanism is specifically composed of a threaded rod 16, a limit rod 17, a T-shaped brush 18, a hand wheel 19, a discharge port and a sealing plug 20;

[0043] The threaded rod 16 is respectively connected to the upper inner walls on both sides of the casing 1 through two sealed bearings, the limit rod 17 is welded to the upper inner wall of the casing 1, and the T-shaped brush 18 is screwed to the middle of the threaded rod 16. The upper part of the brush 18 is provided with a socket, the inner wall of the socket is slidably connected with the outer wall of the limit rod 17, the hand wheel 19 is fixedly sleeved on the threaded rod 16 and is located outside the casing 1, and it is more convenient to drive thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com