Preparation method and application of coated ferrate composite material

A ferrate and composite material technology, applied in iron compounds, chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to effectively remove PPCPs, complicated process, high removal cost, and achieve good slow release effect and removal efficiency. Enhanced and beneficial effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

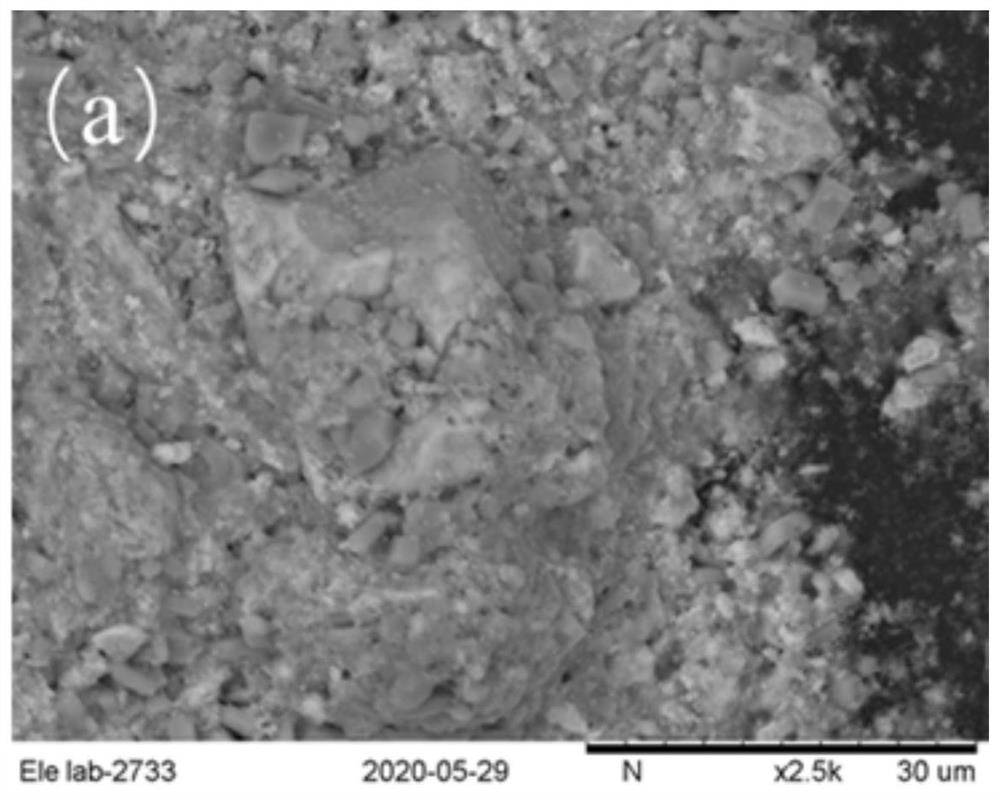

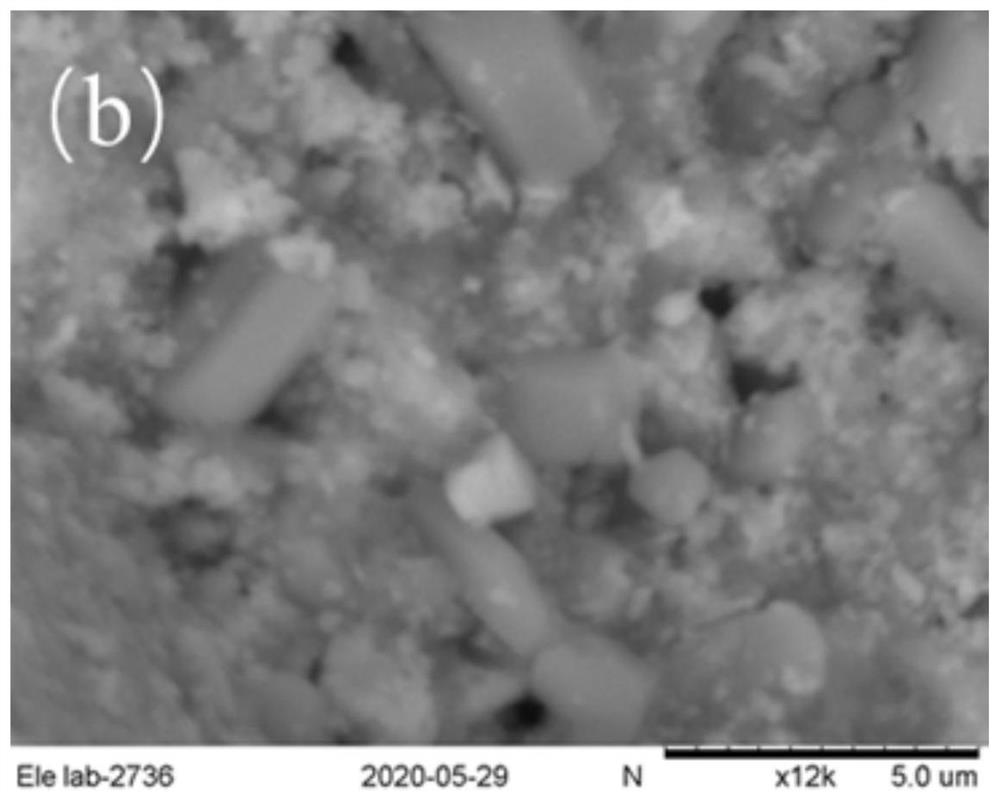

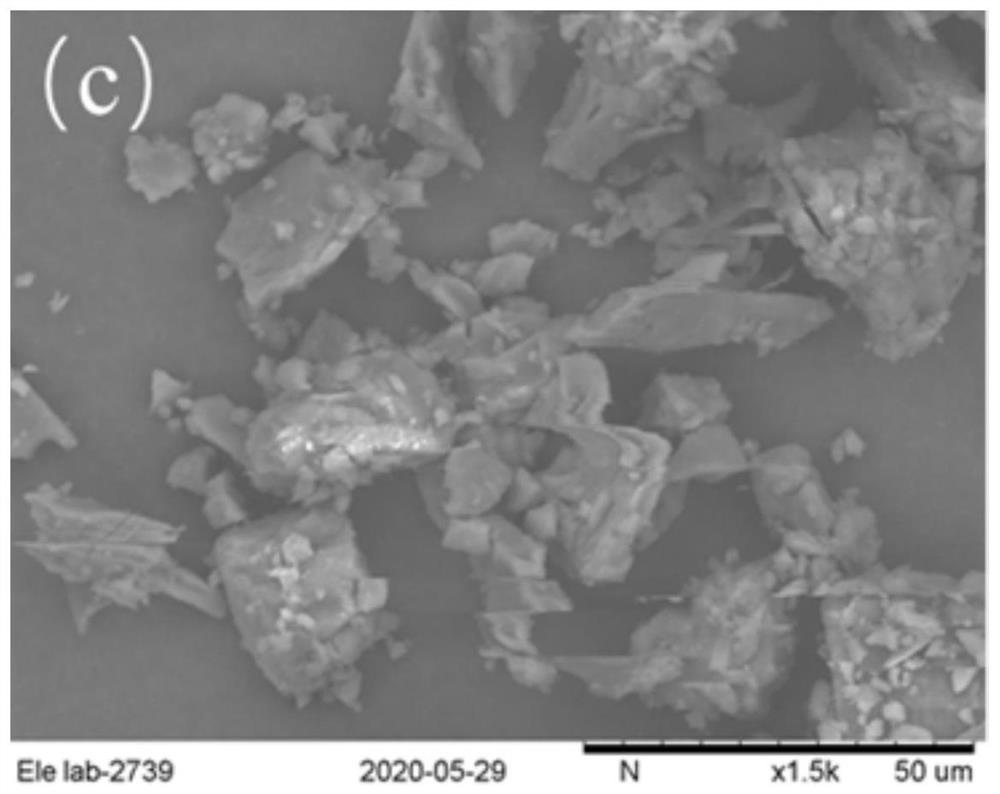

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: The preparation method of a coated ferrate composite material in this embodiment is carried out according to the following steps:

[0031] β-CD is added into ultrapure water, fully dissolved, then ferrate crystals are added, after uniform dispersion, cooled and dried, and finally fully ground to obtain a coated ferrate composite material, the β-CD and The mass ratio of ferrate crystals is 10:1.

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that β-CD is added to ultrapure water and dissolved by heating in a water bath.

[0033] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or 2 in that the ratio of the mass of β-CD to the volume of ultrapure water is (50-100) g:1L.

[0035] Other steps are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com