Lathe body with damping function and using method thereof

A machine body and lathe technology, applied in the field of lathes, can solve the problems of safety and hidden dangers of lathes, and achieve the effects of reducing work intensity, improving safety, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

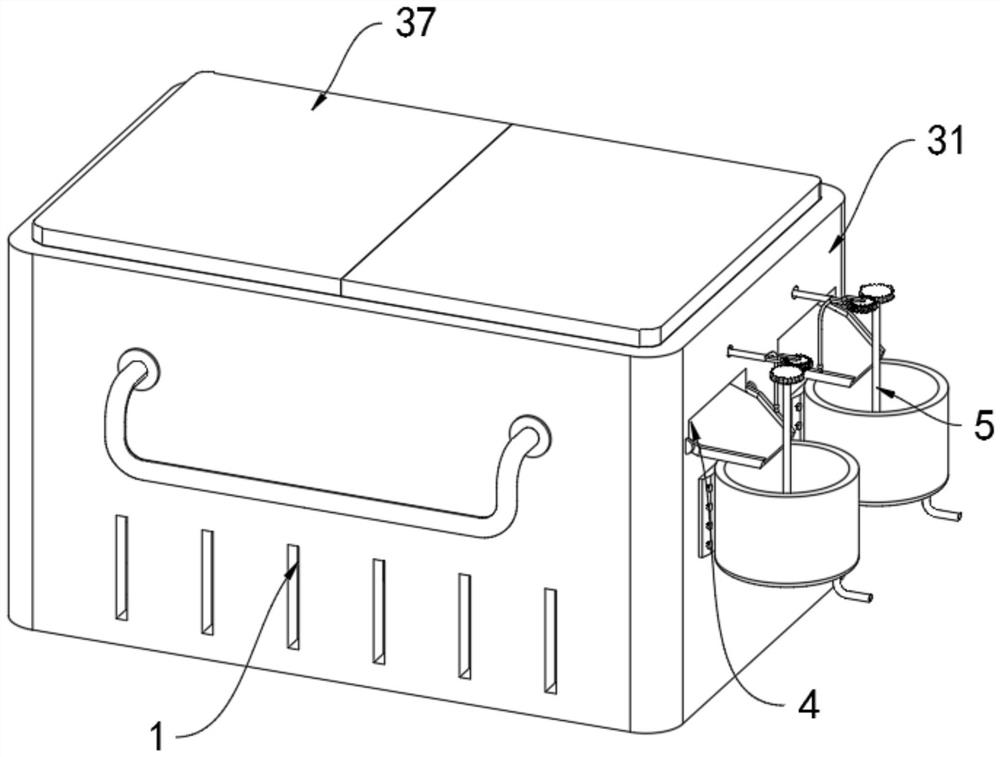

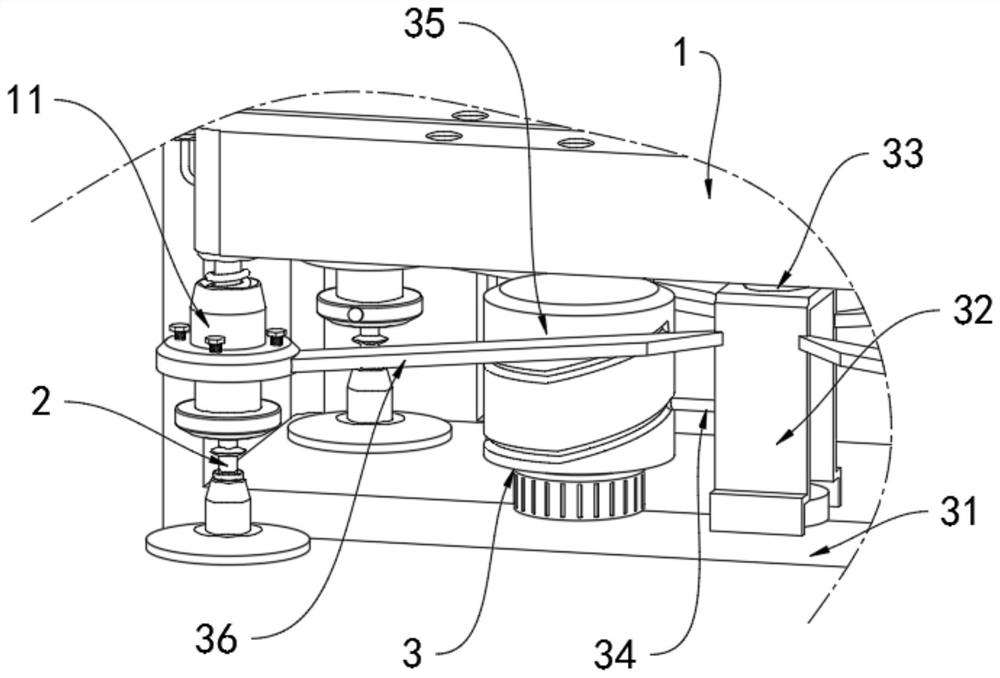

[0060] Please refer to figure 1 and Figure 8 to Figure 10 As shown, a lathe body with shock absorption function includes a lathe body main body 1, the bottom surface of the lathe body main body 1 is evenly distributed with shock absorption components 11, and an auxiliary impurity removal mechanism 4 is arranged above the lathe body main body 1 , the auxiliary impurity removal mechanism 4 includes a blanking hopper 41, a horizontal plate 42, a gas storage piston cylinder 43, a curved rod 44, an impurity removal brush 45, an air pressure valve conduit 46, a transition gap 47, a raised part 48, a bending ball rod 49, The air pressure valve air nozzle 410, the right side surface of the main protective hood 31 is symmetrically formed with a transition gap 47 in the front and rear, and the outer surface of the transition gap 47 and the outer surface of the main protective hood 31 is hinged with a blanking hopper 41, and the blanking hopper 41 The upper surface of the spring rod 48...

Embodiment 2

[0063] Please refer to Image 6 , Figure 8 , Figure 10 As shown, a lathe body with shock absorption function includes a lathe body main body 1, the bottom surface of the lathe body main body 1 is evenly distributed with shock absorption components 11, and an auxiliary impurity removal mechanism 4 is arranged above the lathe body main body 1 , and is located on the side of the auxiliary impurity removal mechanism 4 with a matching separation mechanism 5, which includes a spring rod 51, a push rod 52, a ratchet 53, a gear rod 54, a recovery cylinder 55, a filter plate 56, and a bending ball rod. The upper end of 49 is fixedly connected with a spring rod 51, and the spring rod 51 is inserted into the right side surface of the main protective hood 31 through the spring, the left side of the spring rod 51 is provided with a push rod 52, and the push rod 52 is fixedly connected to the impurity removal. On the upper surface of the brush 45, the push rod 52 and the spring rod 51 a...

Embodiment 3

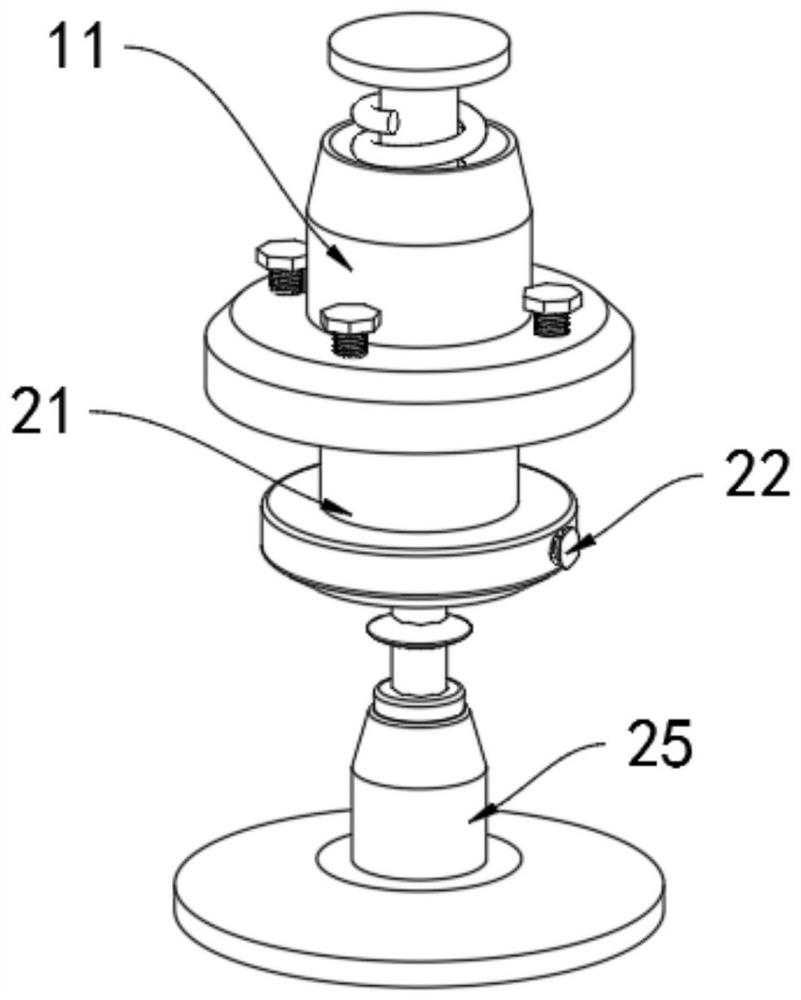

[0066] Please refer to Figure 1 to Figure 11 As shown, a lathe body with shock absorption function includes a lathe body main body 1, the bottom surface of the lathe body main body 1 is evenly distributed with damping components 11, and the bottom of the damping component 11 is evenly provided with a matching buffer mechanism 2 , the matching buffer mechanism 2 includes a matching cavity 21, a spring telescopic rod 22, a wedge-shaped block 23, a hemispherical portion 24, and a sloped collar shaft 25. The bottom of the shock absorber assembly 11 is fixedly connected with the matching cavity 21, and the interior of the matching cavity 21 One side is plugged with a spring telescopic rod 22, and the inner end of the spring telescopic rod 22 is fixedly connected with a wedge-shaped block 23, the inner end of the wedge-shaped block 23 is horizontally abutted with a hemispherical part 24, and the bottom of the hemispherical part 24 is fixedly connected There is an inclined plane col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com