Reconfigurable driving wheel type joint module and driving wheel type snakelike robot thereof

A technology of joint modules and active joints, applied in manipulators, motor vehicles, program-controlled manipulators, etc., can solve the problems of small joint contact friction, low reconfigurability, complex design, etc., and achieve improved mobility, flexibility and convenience Assembly and disassembly, highly reconfigurable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

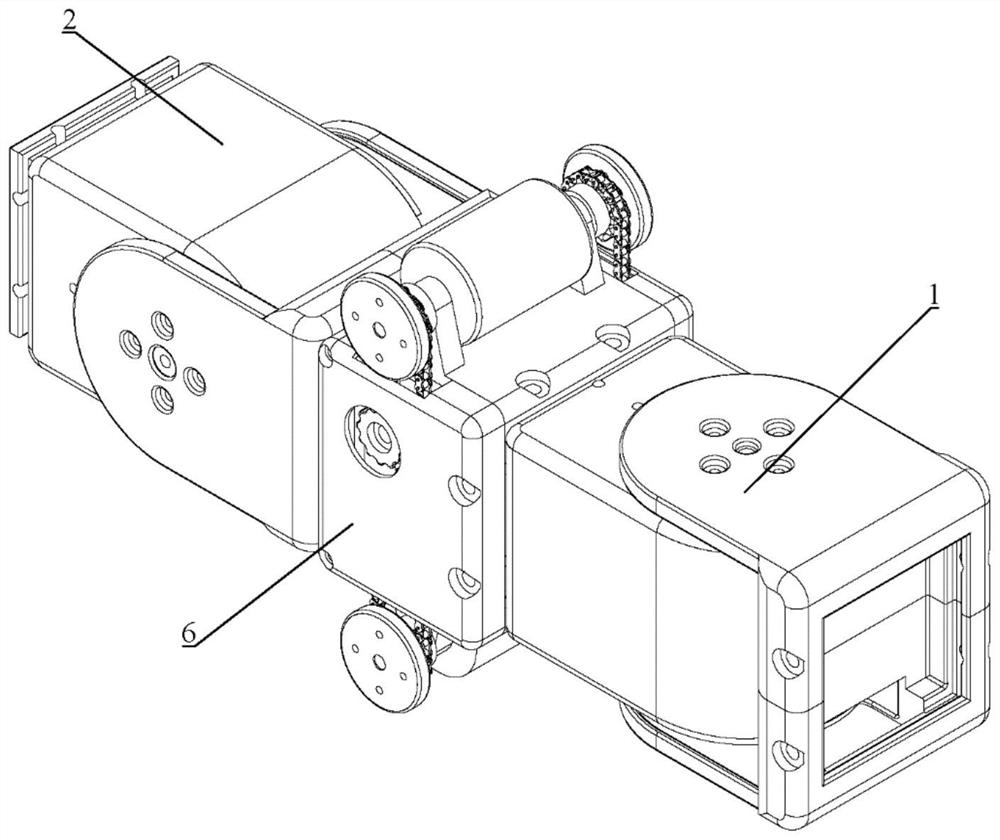

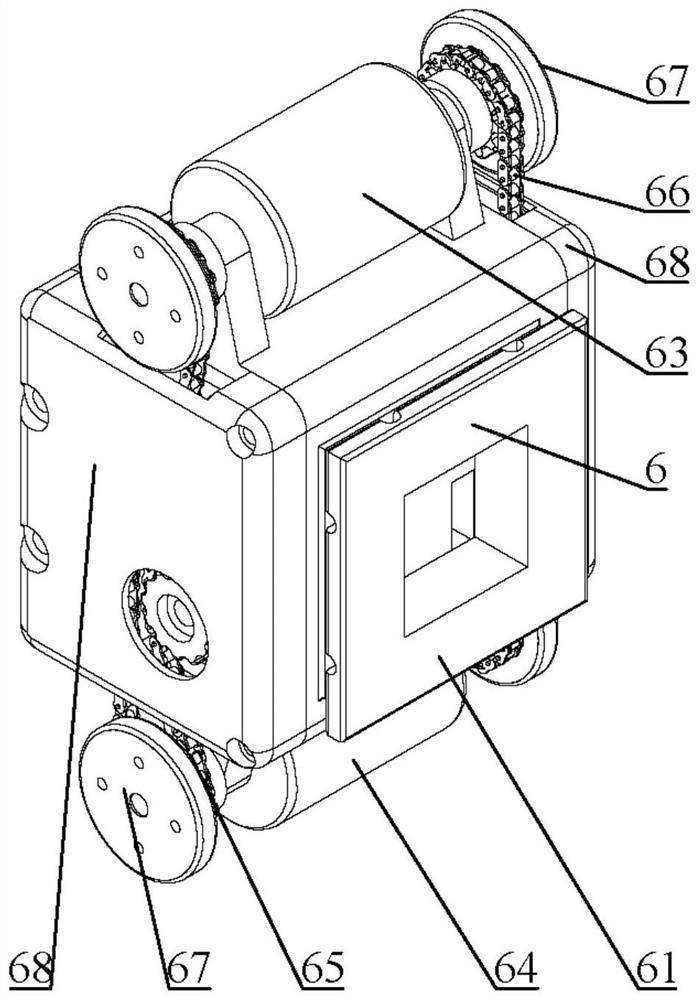

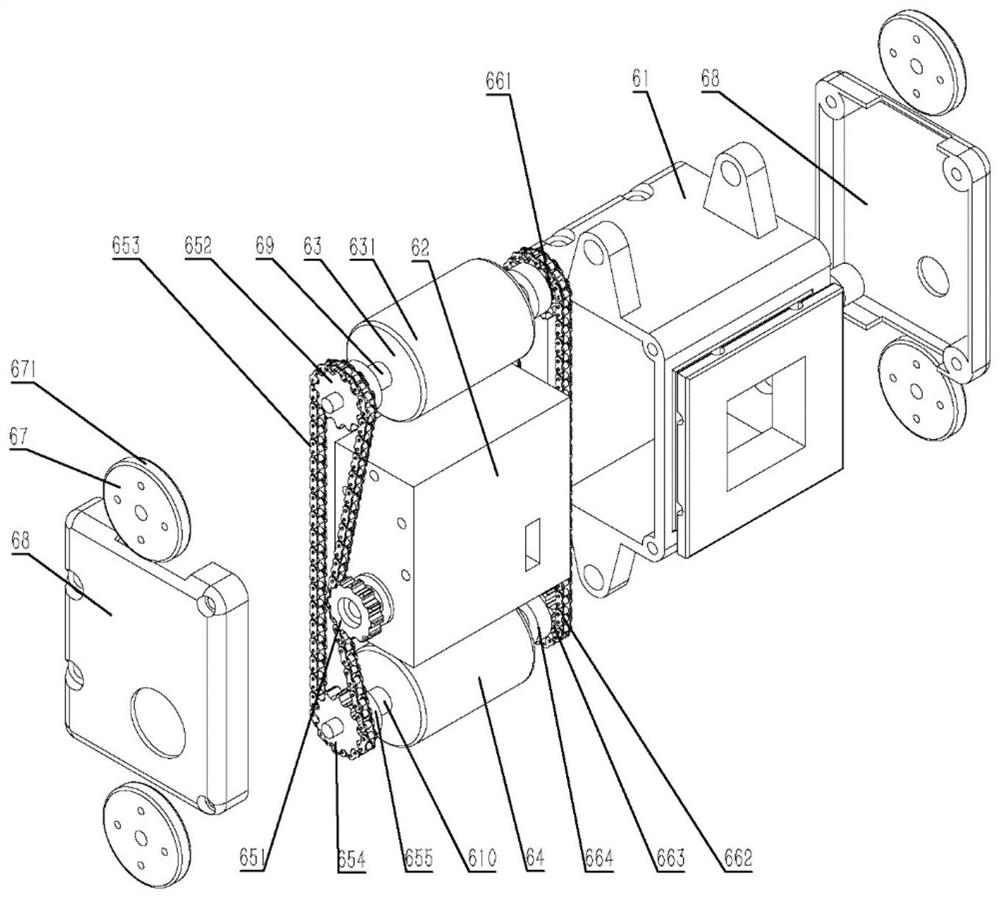

[0055] In this embodiment, a reconfigurable active wheel joint module of the present invention, such as Figure 1 to Figure 8 As shown in the figure, the active steering gear 62 of the active joint unit 6 is first controlled to rotate, and the output gear is engaged with the driving sprocket 651 for transmission. It is connected with the first lower sprocket 654 to form a first chain assembly 65. The first upper sprocket 652 and the first lower sprocket 654 are in interference fit with the upper driving axle 69 and the lower driving axle 610, and the driving steering gear 62 can drive the upper The driving wheel shaft 69 and the lower driving wheel shaft 610 rotate; the upper driving wheel shaft 69 and the lower driving wheel shaft 610 are in an interference fit with the second upper chain wheel 661 and the second lower chain wheel 662 respectively, and the second upper chain wheel 661 and the second lower chain The wheel 662 and the second chain 662 form the second chain asse...

Embodiment 2

[0057] In this embodiment, a reconfigurable active wheel joint module of the present invention, such as Figure 1 to Figure 8 As shown in the figure, the first steering gear 113 in the first joint unit 1 is controlled to rotate, and the output gear 1133 is engaged with the right flange 115 for transmission, and the right flange 115 is fixedly connected with the right connecting joint plate 122, thereby driving the connecting joint 12 Rotate around the rotary joint 11 in the yaw direction, while the first joint unit 1 is fixedly connected to the active joint unit 6, so that the active joint unit 6 can rotate in the yaw direction; control the first steering gear in the second joint unit 2 113 rotates, and the output gear 1133 meshes with the right flange 115 for transmission, and the right flange 115 is fixedly connected with the right connecting joint plate 122, thereby driving the connecting joint 12 to rotate around the rotating joint 11 in the pitch direction, and at the same...

Embodiment 3

[0059] In this embodiment, an active wheeled snake robot of the present invention, such as Figure 10 and Figure 15 As shown, firstly, a plurality of active wheel joint modules are connected end to end, and the orthogonal joint module 3 is driven by the first steering gear 113 in each module to achieve rotational motion in pitch and yaw directions, and the active steering gear 62 drives the active roller 64 and the active steering gear 64. The wheel 67 rotates, and connects the head module 4 and the tail module 5 of the snake-shaped robot, which can form a three-dimensional motion gait with multiple degrees of freedom and drive by the driving wheel. When the first steering gear 113 that controls the yaw direction of the snake robot works, the first steering gear 113 that controls the pitch direction maintains the zero initial position, the active steering gear 62 is in a non-working state, and the steering gears of the adjacent yaw joints work When the angle is output by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com