Urban sewage full-membrane treatment method

A technology for urban sewage and membrane treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of inability to remove heavy metals, poor treatment effect, and inability to remove impurities in sewage. , to improve the effect of sewage treatment, increase the service life, and ensure the effect of normal working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

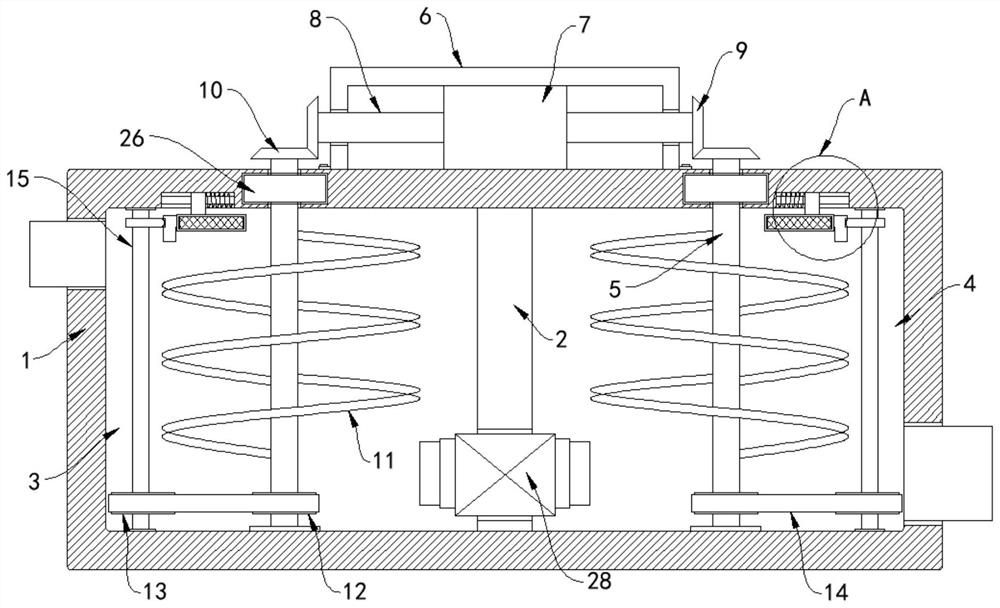

[0036] see Figure 1-5 , an embodiment provided by the present invention: a full-film treatment method for urban sewage, comprising the following steps:

[0037] Step 1, the urban sewage is discharged into the sedimentation tank of the treatment tank through the sewage discharge pipe for sedimentation;

[0038] Step 2, the sewage in the sedimentation tank is deposited for a period of time and then discharged into the biological treatment tank for treatment, and the mud in the sedimentation tank is dehydrated;

[0039] Step 3, adding chemicals to the sewage treated by the biological treatment tank for coagulation and sedimentation, and after filtration, the water is sterilized;

[0040] Step 4, using the connecting pipe to flow the sterilized sewage into the membrane bioreactor to achieve deep purification of the sewage;

[0041] Step 5, landfill the dehydrated mud;

[0042] In step 6, the purified water in step 4 is sent to the reverse osmosis water treatment equipment, and...

Embodiment 2

[0048] see Figure 4 , is another preferred embodiment of the present invention, which has the implementation contents of the above-mentioned embodiments, wherein, for the specific implementation of the above-mentioned embodiments, please refer to the above-mentioned descriptions, and the embodiments here will not be repeated in detail; In the example, the difference between it and the above-mentioned embodiment is:

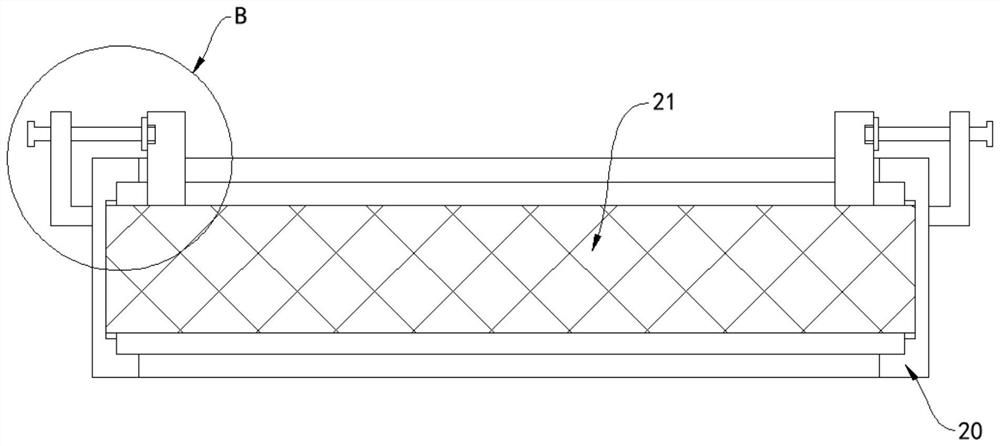

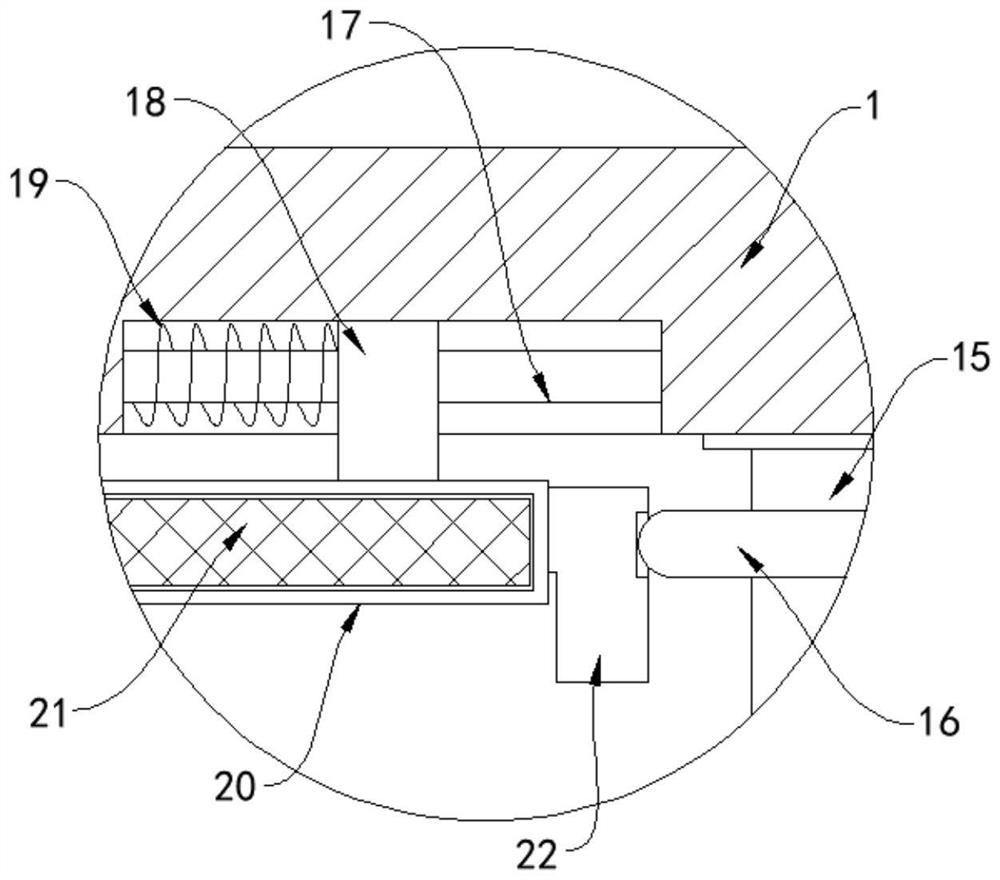

[0049] In this embodiment, the tops of both ends of the filter screen 21 are fixedly connected with locking blocks 23 , and the outer walls of both sides of the hollow cylinder 20 are fixedly connected with vertical plates 24 . One side of the tightening block 23 is provided with a positioning groove corresponding to the positioning rod 25; in particular, by sliding the positioning rod 25 into the positioning groove on the locking block 23, it is convenient to disassemble and assemble the filter screen 21, instead of the traditional screw fixing The method is mo...

Embodiment 3

[0051] see Figure 5 , is another preferred embodiment of the present invention, which has the implementation contents of the above-mentioned embodiments, wherein, for the specific implementation of the above-mentioned embodiments, please refer to the above-mentioned descriptions, and the embodiments here will not be repeated in detail; In the example, the difference between it and the above-mentioned embodiment is:

[0052] In this embodiment, the medicinal water in step 3 is a flocculant, including 2-10 parts of polyvinyl alcohol solution, 67 parts of large-density granular powder, and 50 parts of inorganic flocculant fine powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com