Method for preparing high-purity rebaudioside b by alkaline hydrolysis of rebaudioside a

A high-purity and alkaline technology, applied in the field of stevioside, can solve the problems of high cost, low rebaudioside b content, and unsatisfactory yield, etc., and achieve the effects of high selectivity, high product purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

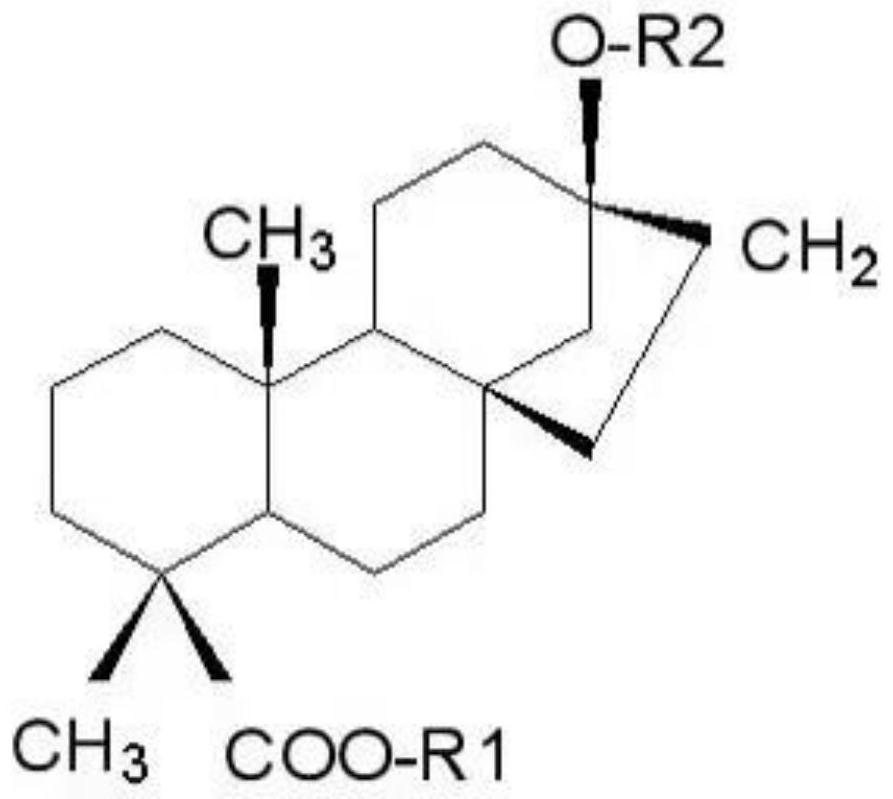

Image

Examples

Embodiment 1

[0031] Weigh 50 g of rebaudioside a with a purity of 95% (mass percentage), add 1 L of water to dissolve, add saturated sodium hydroxide solution to adjust pH to 12, stir at a temperature of 95 ° C for constant temperature reaction for 4 h, add hydrochloric acid to adjust pH To 7.0, after standing at 20°C for 16 hours, a large amount of white precipitate was precipitated, which was washed with water after filtration (vacuum filtration), dried and detected by liquid phase.

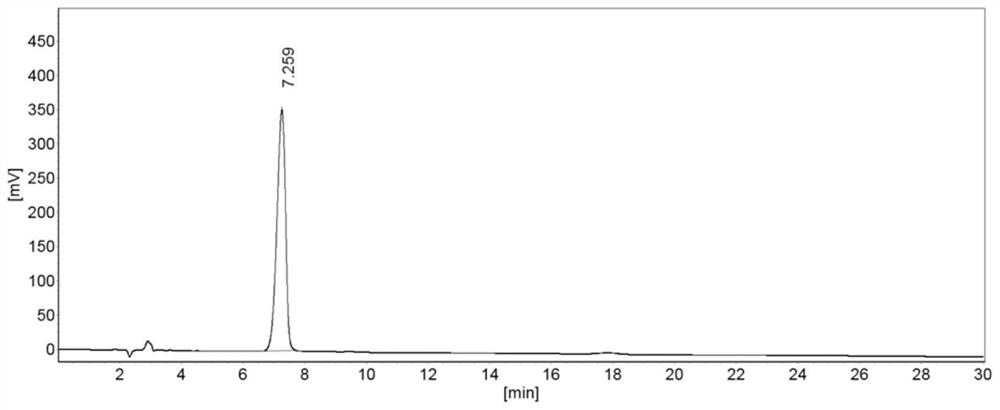

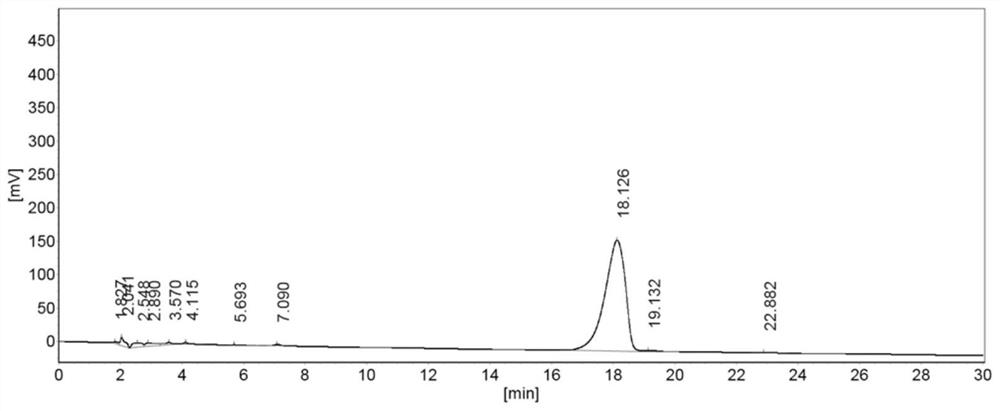

[0032] The liquid chromatogram of rebaudioside a reference substance is as follows figure 2 As shown, the liquid chromatogram of the rebaudioside b reference substance is shown in image 3 As shown, the liquid chromatogram of the sample is shown in Figure 4 shown.

[0033] Qualitative and quantitative analysis of the reference substance and rebaudioside b sample of rebaudioside a and rebaudioside b by HPLC (the detection method refers to the national standard of steviol glycosides), the retention of the...

Embodiment 2

[0038] Weigh 50 g of rebaudioside a with a purity of 95%, add 1 L of water to dissolve, add saturated sodium hydroxide solution to adjust the pH to 12, stir at a temperature of 60 °C for constant temperature reaction for 4 h, add hydrochloric acid to adjust the pH to 7.0, and at 20 °C After standing for 16 hours, a large amount of white precipitates were precipitated. After filtration and washing, and liquid phase detection after drying, the yield of rebaudioside b was 76.3%, and the purity was 90.1%.

Embodiment 3

[0040] Weigh 50 g of rebaudioside a with a purity of 50%, add 1 L of water to dissolve, add saturated sodium hydroxide solution to adjust the pH to 12, stir and react at a constant temperature of 95 °C for 4 h, add hydrochloric acid to adjust the pH to 7.0, and adjust the pH to 7.0 at 4 °C. After standing for 16 hours, a large amount of white precipitates were precipitated. After filtration and washing, and liquid phase detection after drying, the yield of rebaudioside b was 83.3%, and the purity was 85.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com