Complex iron desulfurization technological process suitable for sulfur-containing shale oil associated gas

A technology of process flow and associated gas, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of high concentration, high water content, unsatisfactory economy and safety, etc., and achieve the effect of simple process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

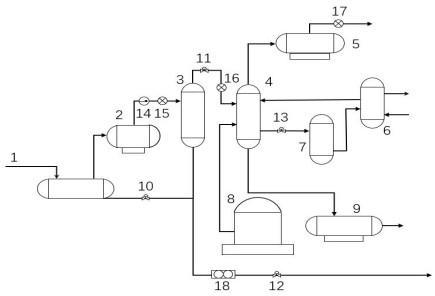

[0020] The first step: close the first valve 10, the second valve 11, the third valve 12, and the fourth valve 13;

[0021] The second step: open the raw material gas separator 1 and the cooling device 2, and carry out gas-liquid separation and dust removal and purification work, so that the temperature can meet the requirements of the subsequent wet desulfurization tower 3. The separated crude oil is measured by the crude oil export flow meter 18 and then exported;

[0022] The third step: monitor the temperature and pressure at the outlet of the cooling device through the first thermometer 14 and the first pressure gauge 15, so that the conditions are met: the temperature is 25-45°C, and the pressure is 1.2MPa-4.6MPa;

[0023] The fourth step: open the first valve 10, the second valve 11, the third valve 12; close the fourth valve 13;

[0024] The fifth step: make the gas that meets the pressure and temperature requirements after passing through the cooling device 2 enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com