Al-Zn-Fe series motor rotor alloy and preparation method and application thereof

A motor rotor and alloy technology, which is applied in the field of new energy vehicle motor rotor materials, can solve the problem that rotor alloys cannot take into account excellent high temperature creep resistance and mechanical properties at the same time, and achieve increased diffusion activation energy, good anti-crack properties, The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

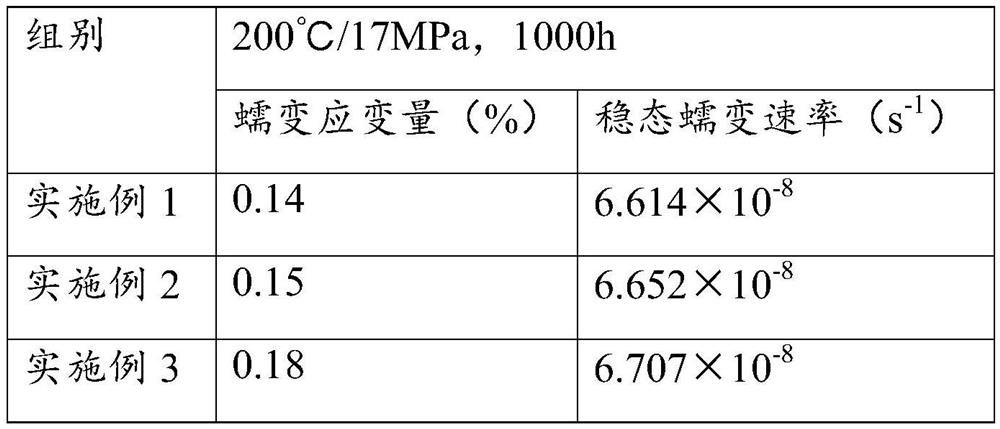

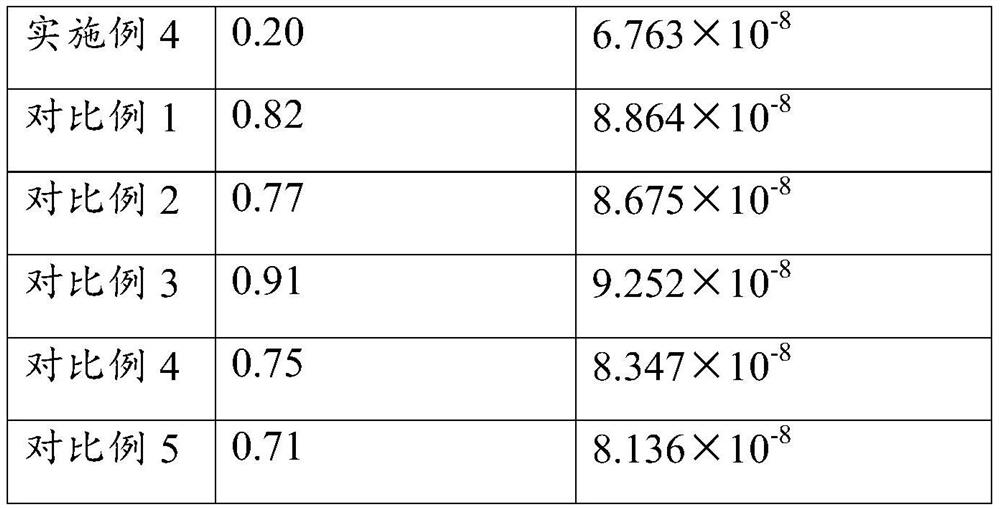

Examples

Embodiment 1

[0026] An Al-Zn-Fe series motor rotor alloy comprises the following components in mass percentage: Zn: 0.5%, Fe: 0.4%, Si: 0.1%, and the balance is Al.

[0027] The preparation method of the Al-Zn-Fe series motor rotor alloy comprises the following steps:

[0028] (1) According to the composition ratio of the Al-Zn-Fe series motor rotor alloy, add zinc-containing material, iron-containing material and aluminum-containing material into the smelting furnace, and smelt at 710 ° C to obtain a molten liquid;

[0029] (2) adding Si to step (1) molten liquid, then adding melt mass 0.5wt% nitrogen gas to carry out melt refining treatment, refining temperature is 740 ℃, treatment time is 10min;

[0030] (3) The melt was allowed to stand for more than 30 min, and cast at 715° C., and centrifugal casting treatment was performed, and the centrifugal casting speed was 300 r / min to obtain an Al-Zn-Fe motor rotor alloy.

Embodiment 2

[0032] An Al-Zn-Fe series motor rotor alloy comprises the following components in mass percentage: Zn: 1.8%, Fe: 0.2%, Si: 0.3%, and the balance is Al.

[0033] The preparation method of the Al-Zn-Fe series motor rotor alloy comprises the following steps:

[0034] (1) According to the composition ratio of the Al-Zn-Fe series motor rotor alloy, add zinc-containing material, iron-containing material and aluminum-containing material into the smelting furnace, and smelt at 750 ° C to obtain a molten liquid;

[0035] (2) adding Si to step (1) molten liquid, then adding melt mass 0.8wt% hexachloroethane to carry out melt refining treatment, refining temperature is 720 ℃, treatment time 30min;

[0036] (3) The melt was allowed to stand for more than 30 minutes, cast at 730° C., and centrifugally cast with a rotational speed of 200 r / min to obtain an Al-Zn-Fe-based motor rotor alloy.

Embodiment 3

[0038] An Al-Zn-Fe series motor rotor alloy comprises the following components in mass percentage: Zn: 2.0%, Fe: 0.1%, Cu: 0.6%, and the balance is Al.

[0039] The preparation method of the Al-Zn-Fe series motor rotor alloy comprises the following steps:

[0040] (1) According to the composition ratio of the Al-Zn-Fe series motor rotor alloy, add zinc-containing material, iron-containing material and aluminum-containing material into the smelting furnace, and smelt at 730 ° C to obtain a molten liquid;

[0041] (2) adding Cu to the molten liquid in step (1), then adding 1wt% argon gas of the melt mass to carry out melt refining treatment, the refining temperature is 740°C, and the treatment time is 20min;

[0042] (3) The melt is allowed to stand for more than 30 minutes, cast at 720° C., centrifugally casted, and the rotational speed of centrifugal casting is 240r / min to obtain an Al-Zn-Fe series motor rotor alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com