Sodium persulfate micro-etching additive and application thereof

A technology of sodium persulfate and additives, applied in the field of sodium persulfate micro-etching additives, can solve the problems of inability to obtain the amount of bite corrosion, high cost of use, reduction of the amount of bite corrosion and bite corrosion rate, etc. Dosage, effect of promoting sustained response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of sodium persulfate micro-etching additive, by every 1kg, each component and its corresponding weight are as shown in table 1, and make by following preparation method:

[0037] Weigh azole compound, narrow distribution alkyl alcohol ether, triazine compound, silane coupling agent and water according to the proportion and mix at 2000r / min for 30min until uniform to obtain sodium persulfate micro-etching additive;

[0038] The azole compound is 2-aminobenzimidazole, the narrow distribution alkyl alcohol ether is Berol 260, the triazine compound is 2,4,6 tris(aminocaproic acid group)-1,3,5 triazine, silane coupling The joint agent is KH-570.

Embodiment 2-6

[0040] A kind of sodium persulfate micro-etching additive, the difference from Example 1 is that each component and its corresponding weight are as shown in Table 1.

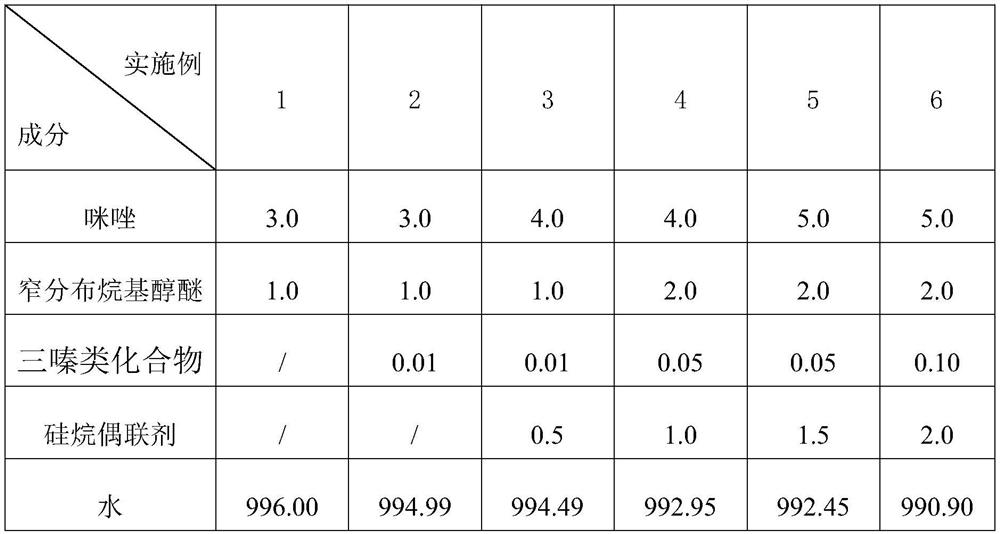

[0041] Each component of sodium persulfate micro-etching additive and its weight (g) in the embodiment 1-6 of table 1

[0042]

Embodiment 7

[0044] A sodium persulfate micro-etching additive, the difference from Example 1 is that the azole compound is 2-aminothiazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com