Hydrogen production method

A hydrogen and metal technology, applied in the fields of hydrogen production and chemistry, can solve the problems of extremely high safety requirements for long-distance transportation and storage, the long distance between hydrogen production efficiency and hydrogen consumption, and high working conditions, achieving continuous production. Effects of hydrogen operation, increasing energy burden, and solving safety problems in long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

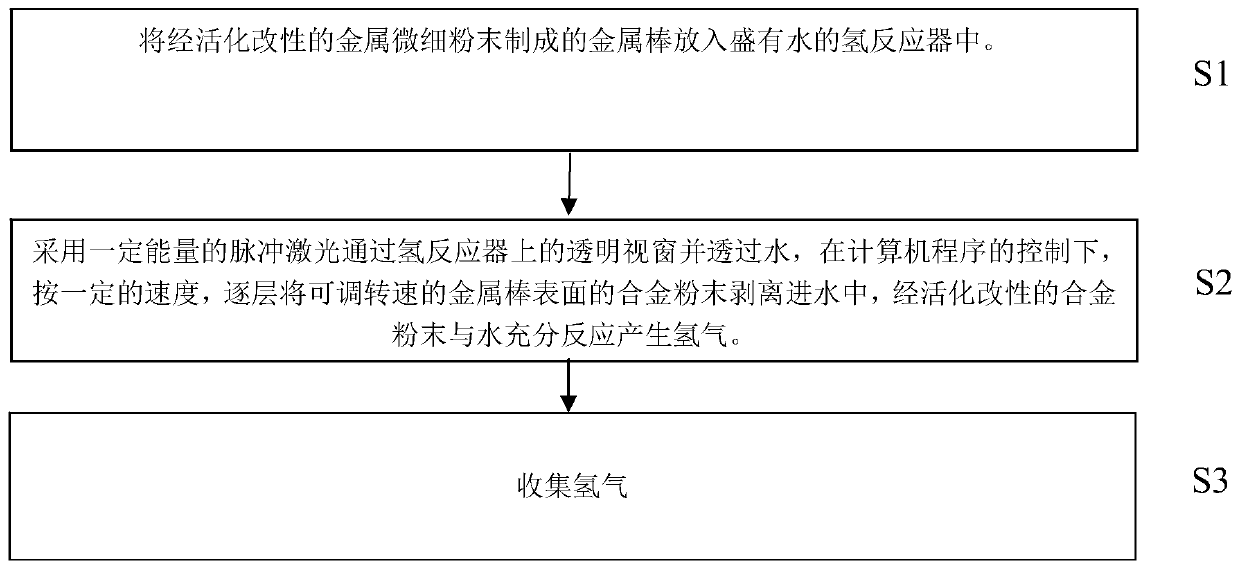

Method used

Image

Examples

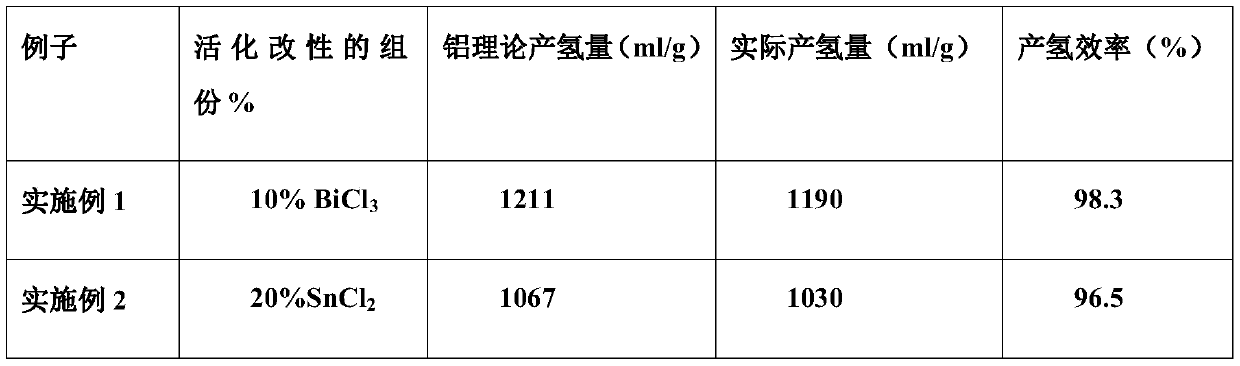

Embodiment 1

[0054] In the aluminum metal powder, the particle size is 0.1um ~ 100um, add 10% of the total amount of BiCl 3 , carry out ball milling, and the transformation reaction adopted by metal activation modification is as follows:

[0055] Al+BiCl 3 =>AlCl 3 +Bi

[0056] The activated modified metal aluminum alloy fine powder is pressed and sintered at low temperature to prepare the aluminum alloy powder rod.

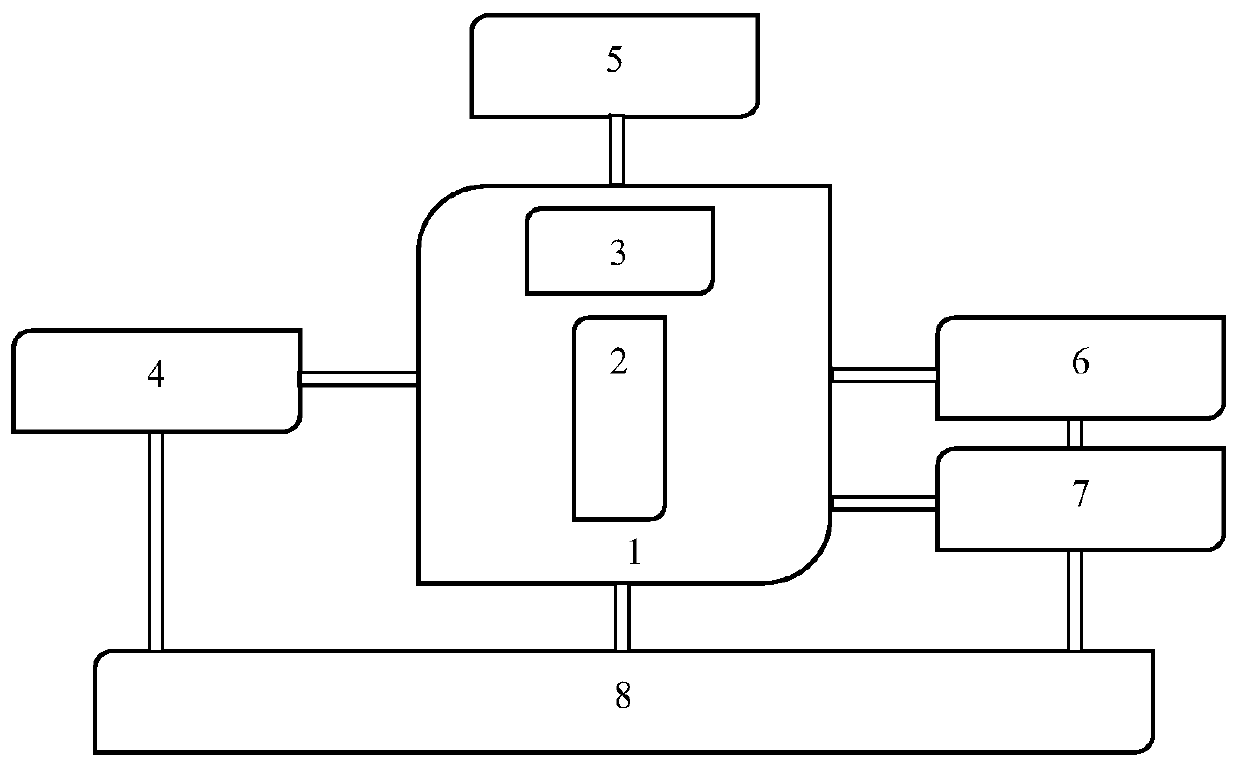

[0057] Put the above-mentioned aluminum alloy powder rod into a hydrogen reactor filled with seawater, and use such as figure 2 The apparatus shown was used for the reaction. A picosecond laser with a wavelength of 1064nm, a pulse energy of 100 microjoules, and a working frequency of 50Khz is used to pass through the transparent ceramic window of the hydrogen reactor and pass through water. Under the control of a pre-programmed computer program, set the corresponding scanning speed. The layer peels off the alloy powder on the surface of the rotating aluminum alloy powde...

Embodiment 2

[0060] In the aluminum metal powder, the particle size is 0.1um ~ 100um, add 20% of the total amount of SnCl 2 , carry out ball milling, and the transformation reaction adopted by metal activation modification is as follows:

[0061] 2Al+3SnCl 2 =>2AlCl 3 +3Sn

[0062] Aluminum alloy powder rods were prepared by additive manufacturing the activated modified metal aluminum alloy fine powder.

[0063] Put the alloy energy bar obtained above into a hydrogen reactor filled with seawater;

[0064] A picosecond laser with a wavelength of 1064nm, a pulse energy of 100 microjoules, and a working frequency of 50Khz is used to pass through the transparent ceramic window of the hydrogen reactor and penetrate water. Under the control of a pre-programmed computer program, the corresponding scanning is set according to the process conditions. Speed, the alloy powder on the surface of the rotating metal aluminum alloy energy bar is peeled off layer by layer into the water, and the activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com