Cleaning agent and cleaning process for aluminum alloy decorating part

A technology for decorative parts and aluminum alloys, which is applied in the field of cleaning agents and cleaning processes for aluminum alloy decorative parts, can solve problems such as corrosion, product damage, and yellowing, and achieve the effects of simple and fast operation, good environmental protection, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

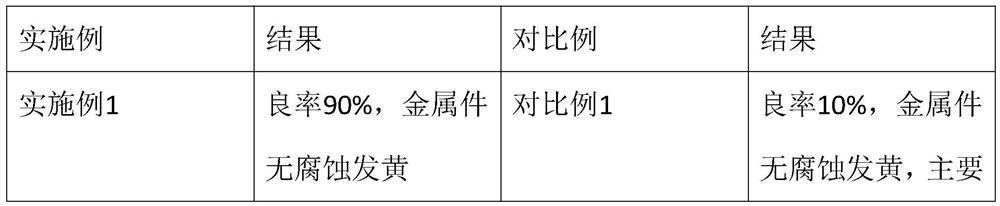

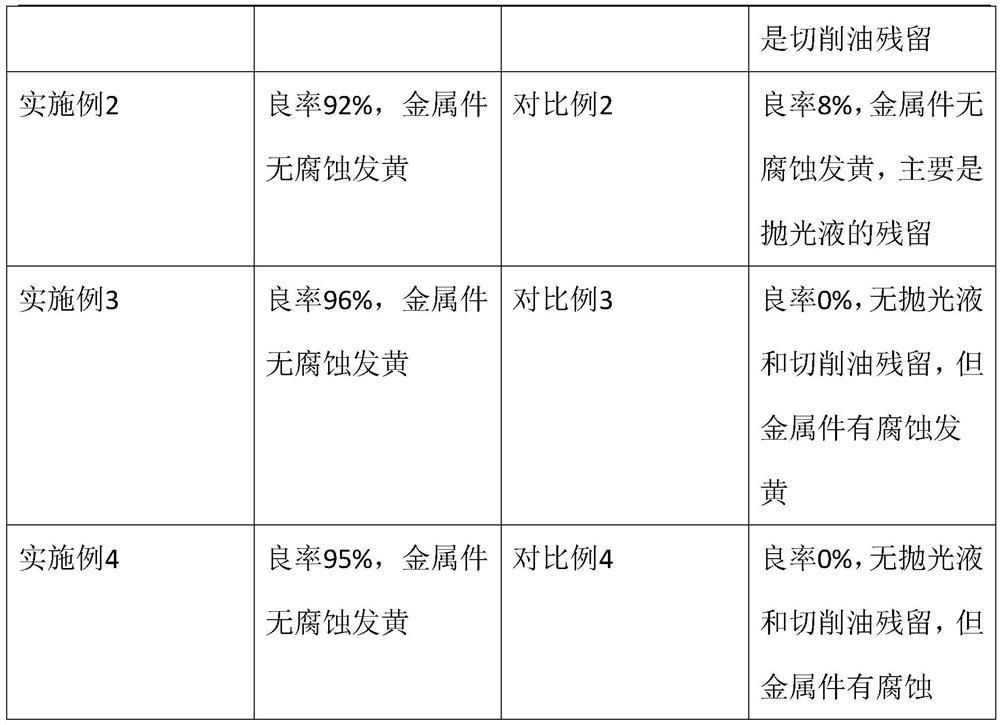

Examples

Embodiment 1

[0017] The cleaning agent, calculated in parts by mass, includes: 5 parts of sodium bicarbonate, 8 parts of sodium pyrophosphate, 8 parts of sodium aminotriacetate, 6 parts of ethylenediaminetetraacetic acid, 6 parts of fatty acid polyoxyethylene ester, 6 parts of polyacrylamide, 3 parts of propylene glycol block polyether, and the balance is water.

Embodiment 2

[0026] The cleaning agent, calculated in parts by mass, includes: 7 parts of sodium bicarbonate, 8 parts of sodium pyrophosphate, 8 parts of sodium aminotriacetate, 6 parts of ethylenediaminetetraacetic acid, 6 parts of fatty acid polyoxyethylene ester, 6 parts of polyacrylamide, 3 parts of propylene glycol block polyether, and the balance is water.

Embodiment 3

[0035] The cleaning agent, calculated in parts by mass, includes: 10 parts of sodium bicarbonate, 8 parts of sodium pyrophosphate, 8 parts of sodium aminotriacetate, 6 parts of ethylenediaminetetraacetic acid, 6 parts of fatty acid polyoxyethylene ester, 6 parts of polyacrylamide, 3 parts of propylene glycol block polyether, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com