Device and method for recovering urea and simultaneously producing struvite

A technology of struvite and urea, applied in fertilization equipment, chemical instruments and methods, preparation of urea derivatives, etc., can solve the problems of high energy consumption, difficult crystallization, and no promotion value, and achieve the effect of promoting ion migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

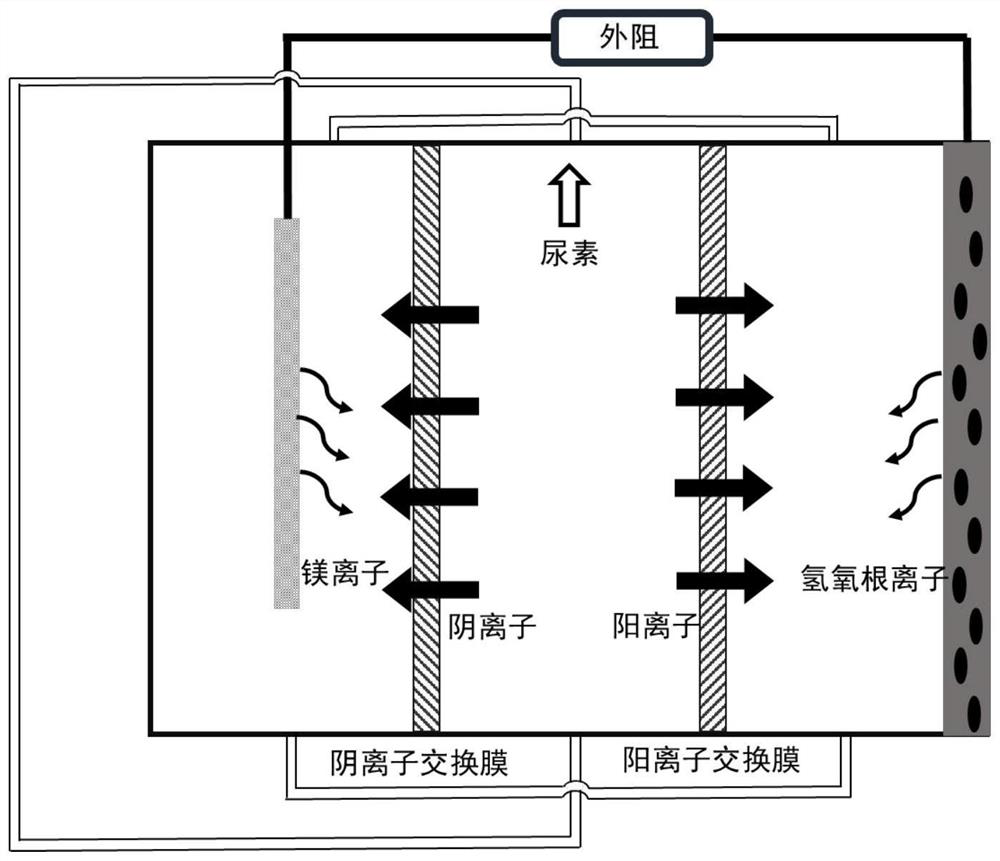

[0071] The device for recovering urea and producing struvite at the same time is composed of a cavity, an external circuit and an external circulation system. The cavity is composed of an anode chamber, an intermediate chamber and a cathode chamber arranged in sequence along the horizontal direction. The exchange membrane is separated, the cathode chamber and the intermediate chamber are separated by a cation exchange membrane, the anode chamber and the cathode chamber are respectively used to hold the electrolyte, and the intermediate chamber is used to hold the urine to be treated;

[0072] The anode chamber and the cathode chamber are connected through an external circulation system, which consists of a pipeline and a peristaltic pump installed on the pipeline; a magnesium plate anode is set in the anode chamber, and a platinum carbon air cathode is set in the cathode chamber; the external circuit consists of wires and external resistors The anode and cathode are connected i...

Embodiment 2

[0075] The device for recovering urea and producing struvite at the same time: it consists of a cavity, an external circuit, an external circulation system, a high-precision voltmeter and a data acquisition system. The compartment and the intermediate compartment are separated by an anion exchange membrane, the cathode compartment and the intermediate compartment are separated by a cation exchange membrane, the anode compartment and the cathode compartment are respectively used to hold the electrolyte, and the intermediate compartment is used to hold the urine to be treated , the anode chamber and the cathode chamber are connected through an external circulation system composed of a hose and a peristaltic pump installed on the hose; wherein, the material of the cavity is plexiglass, the size is 7cm×7cm×2.5cm, and the volume of the cathode chamber is 30mL, the anode compartment volume is 30mL; the cation exchange membrane is CMI7000 (MembranesIiternational Inc, USA), the size is...

Embodiment 3

[0081] The method for reclaiming urea to produce struvite simultaneously, using the device in Example 1:

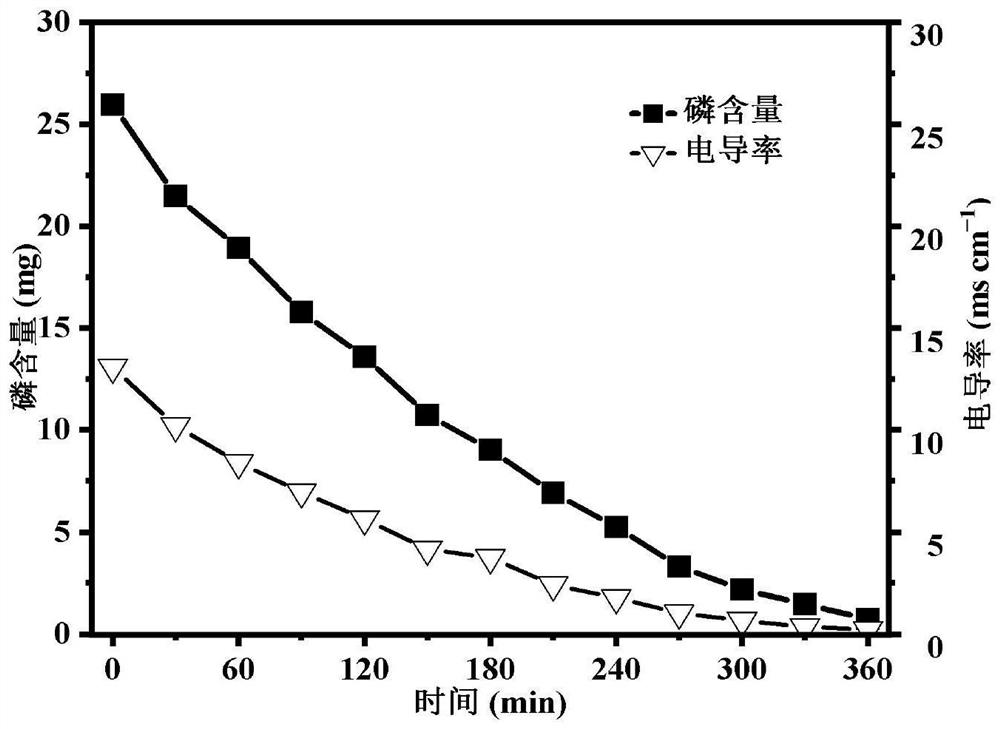

[0082] (1) Urine to be processed: 1.5g / LNa 2 SO 4 , 2.13g / LNaH 2 PO 4 ·2H 2 O 4 , 3g / LNaCl, 1.06g / LKCl, 0.67g / LNH 4 Cl, 0.689g / LNaOH, 2.19g / LNH 4 HCO 3 , 9.09mL / L ammonia water and 14.99g / L urea, the initial concentration of phosphorus is 440.12mg / L, and the initial conductivity is 13.08ms / cm; Inject 1g / LNa respectively 2 SO 4 , the anode and cathode are connected in series with the external resistance through the wire to form a primary battery for electrolysis, and at the same time, the peristaltic pump is turned on to circulate the electrolyte in the anode chamber and the cathode chamber. The flow rate is 2mL / min;

[0083] The anode magnesium plate and the air cathode spontaneously form an electric field, so that the cations in the urine migrate to the cathode compartment, and the anions migrate to the anode compartment to realize the separation of urea, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com