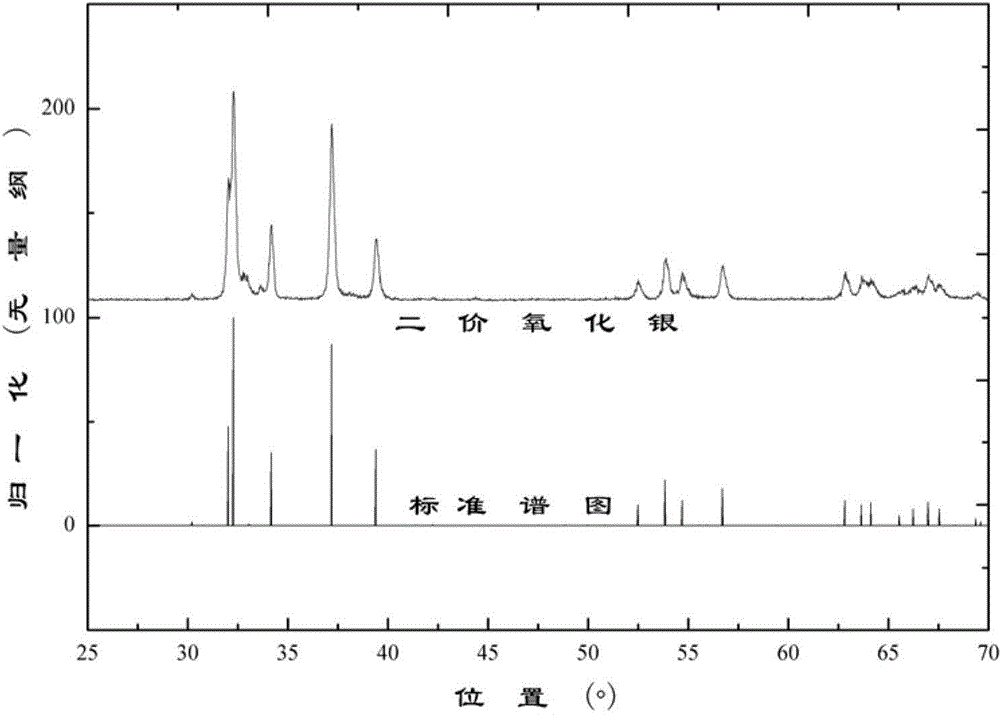

Preparation method of nanocluster divalent silver oxide positive electrode material

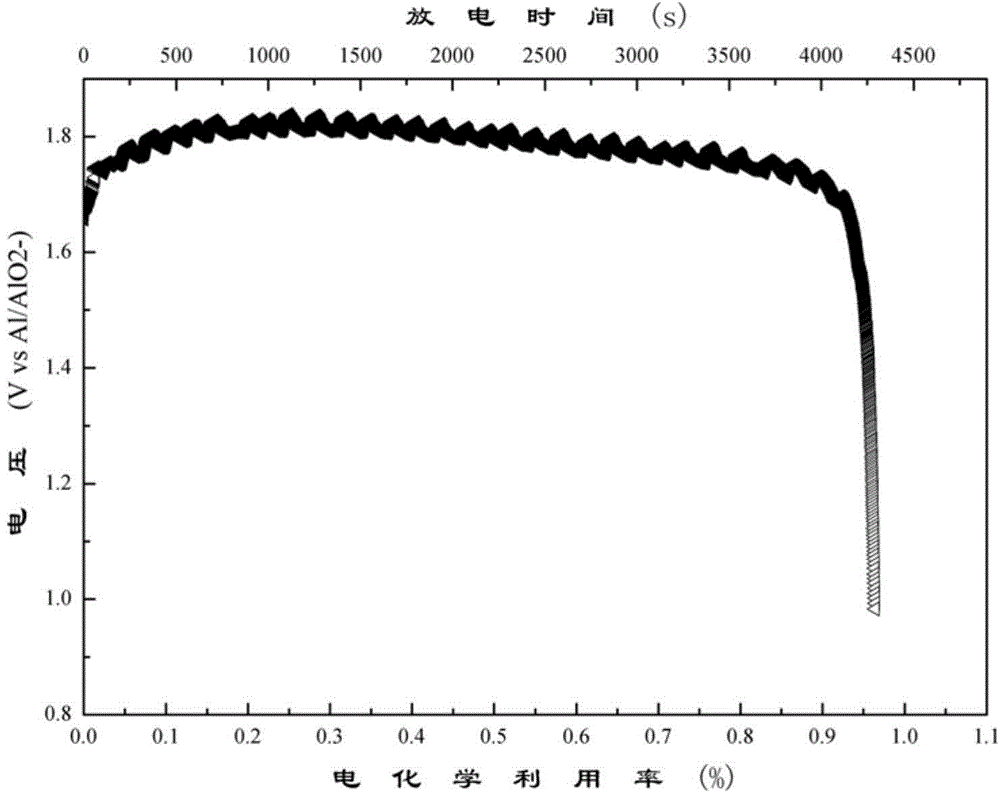

A technology for cathode materials and nano-clusters, which is applied in the field of preparation of nano-cluster divalent silver oxide cathode materials, can solve the problems of difficult to improve electrochemical characteristics, complicated preparation process, and inducers, etc., and achieve excellent discharge rate, The effect of simple preparation process and low electrode polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the nano-cluster divalent silver oxide cathode material is characterized in that it comprises pressing the silver powder into a silver sheet, and the silver sheet is subjected to electrochemical pulse oxidation in an alkaline solution, washed and dried, and the nano-cluster bivalent Preparation process of silver oxide cathode material.

[0020] The silver flakes are formed by pressing dried and sieved silver powder in a vacuum drying oven; the electrochemical pulse oxidation is as follows: (1) select stainless steel flakes with a size slightly larger than the size of the silver flakes and place them on both sides of the silver flakes. The silver piece and the stainless steel piece are placed together in the alkaline solution; (2) the silver piece is connected to the positive pole of the pulse generator, and the stainless steel piece is connected to the negative pole of the pulse generator, and the charging current density is 8mA / cm 2 -4mA / cm 2...

Embodiment 1

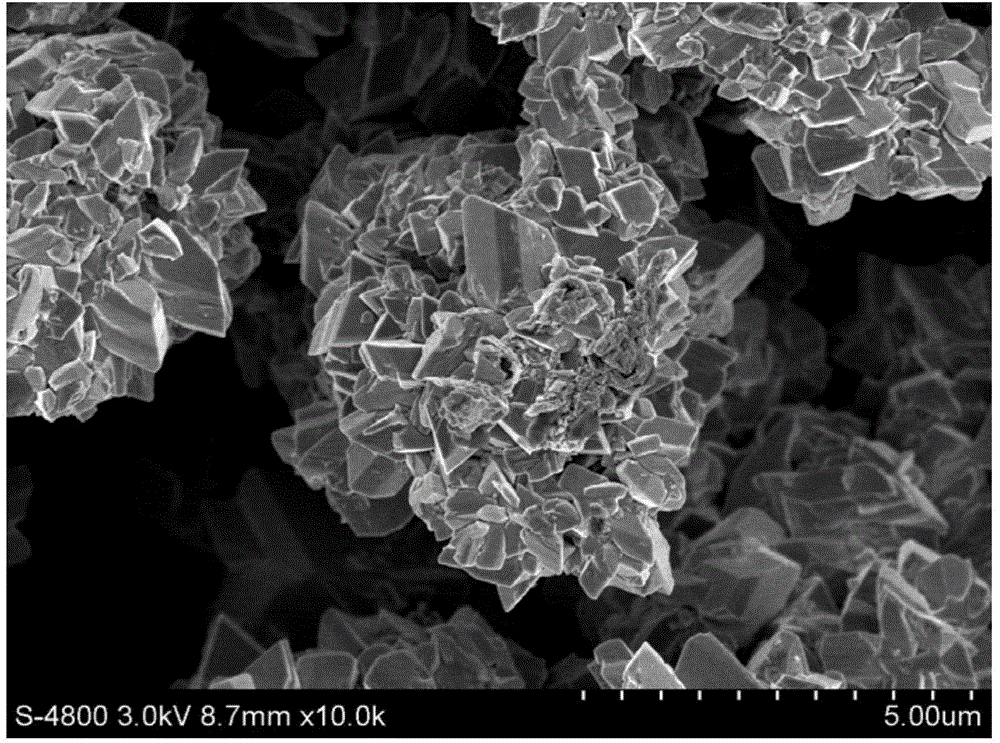

[0025] Put the commercially available silver powder into a vacuum drying oven and dry at 60°C for 24 hours; press the dried silver powder into tablets, and according to the size of the pressed silver sheet, select a stainless steel sheet with a slightly larger size and place it on both sides of the silver sheet. Place it together with the stainless steel sheet in sodium hydroxide solution; the pressed silver sheet is connected to the positive electrode of the DC pulse power supply, and the stainless steel sheet is connected to the negative electrode of the pulse power supply, using 8mA / cm 2 The charge current density, 4mA / cm 2 Discharge current density, pulse frequency is 50Hz, taken out after electrochemical oxidation for 20 hours, washed with distilled water to neutrality, and dried in vacuum at 40°C for 12 hours to obtain nanocrystalline particles with a length of 500 nanometers and a cluster size of 5 microns. Polycrystalline nanocluster divalent silver oxide cathode mater...

Embodiment 2

[0027] Put the commercially available silver powder into a vacuum drying oven and dry at 60°C for 24 hours; press the dried silver powder into tablets, and according to the size of the pressed silver sheet, select a stainless steel sheet with a slightly larger size and place it on both sides of the silver sheet. Place the stainless steel sheet in the calcium hydroxide solution; the pressed silver sheet is connected to the positive electrode of the DC pulse power supply, and the stainless steel sheet is connected to the negative electrode of the DC power supply, using 4mA / cm 2 The charge current density, 2mA / cm 2 Discharge current density, pulse frequency is 30Hz, taken out after electrochemical oxidation for 32 hours, washed with distilled water until neutral, and vacuum-dried at 60°C for 8 hours to obtain nanocrystalline particles with a length of 500 nanometers and a cluster size of 5 microns. Polycrystalline nanocluster divalent silver oxide cathode material. , to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com