Thermal management adjusting system for hydrogen production by alkaline electrolysis water and adjusting method of thermal management adjusting system

A technology for adjusting the system and electrolyzing water, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve problems such as inability to adapt to regulation, device operation stability, limited efficiency of comprehensive energy utilization, and decline in water electrolysis reaction rate, etc., to achieve Save the cost of cooling procedures and corresponding process manufacturing, improve stability and energy utilization efficiency, and maintain the effect of setting the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other.

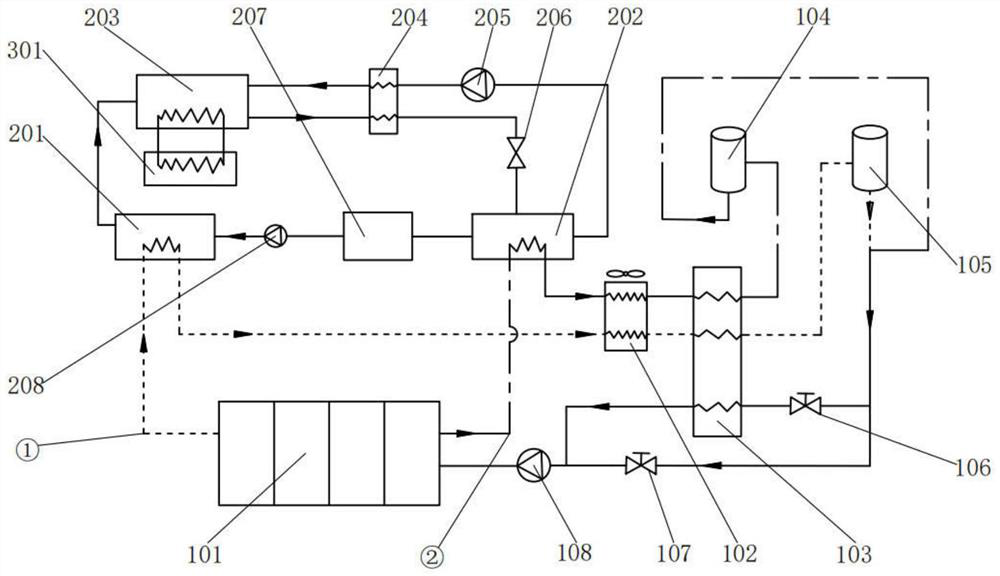

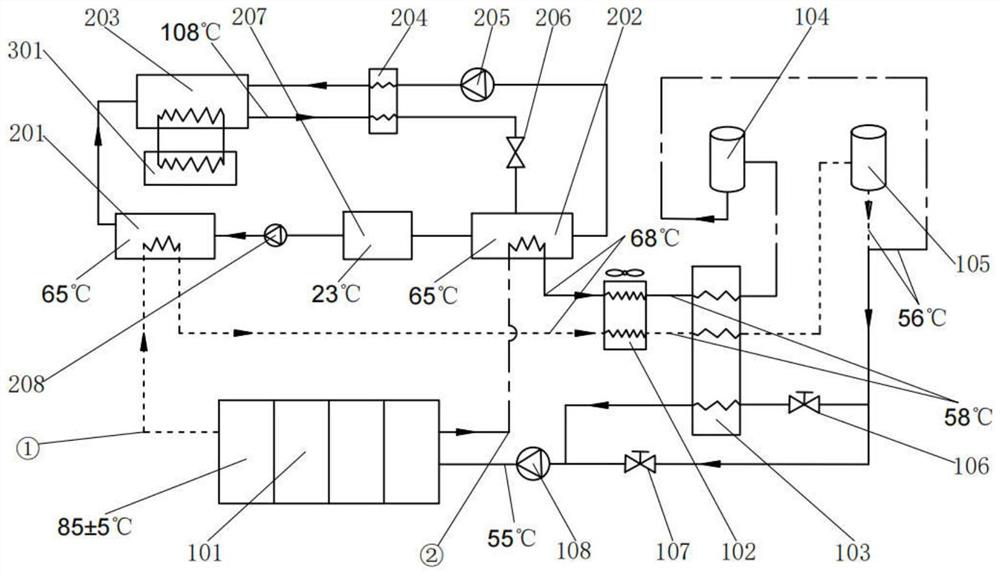

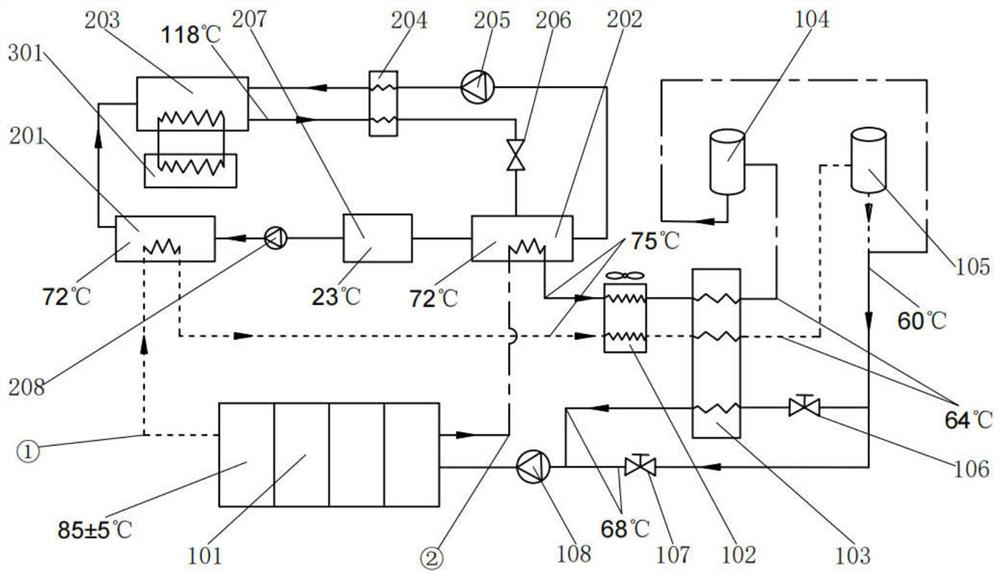

[0026] see figure 1 The present invention provides a thermal management and regulation system for hydrogen production from alkaline water electrolysis. The system includes an electrolysis water hydrogen production subsystem and an absorption heat pump subsystem. The structures of the two subsystems are as follows.

[0027] The absorption heat pump subsystem includes a generator 202 and an evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com