Adjustable modularized grate cooler for lithium ore smelting plant

A modular and grate cooler technology, which is applied in furnaces, lighting and heating equipment, and the treatment of discharged materials, can solve the problems of increasing factory construction costs, long equipment installation periods, and difficulties in meeting the needs of lithium ore clinker transportation and cooling, etc. problem, achieve the effect of reducing the welding workload and reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

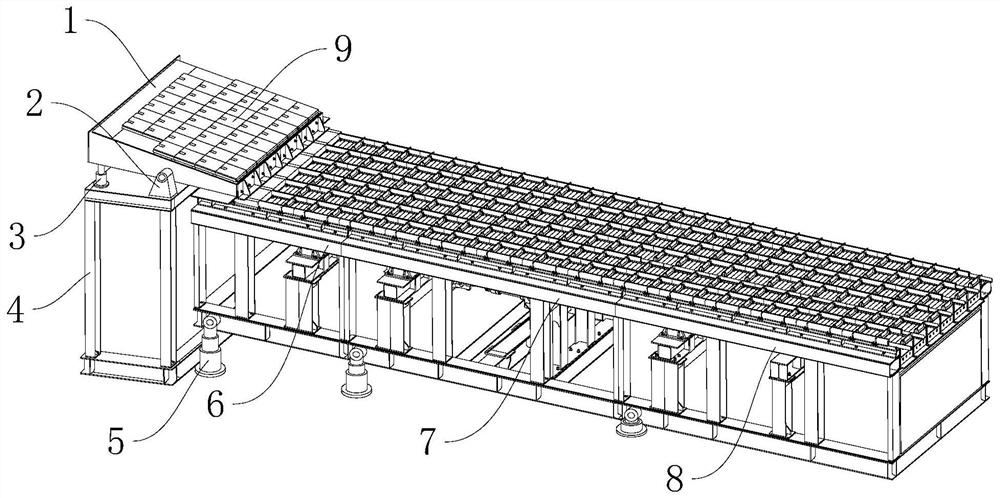

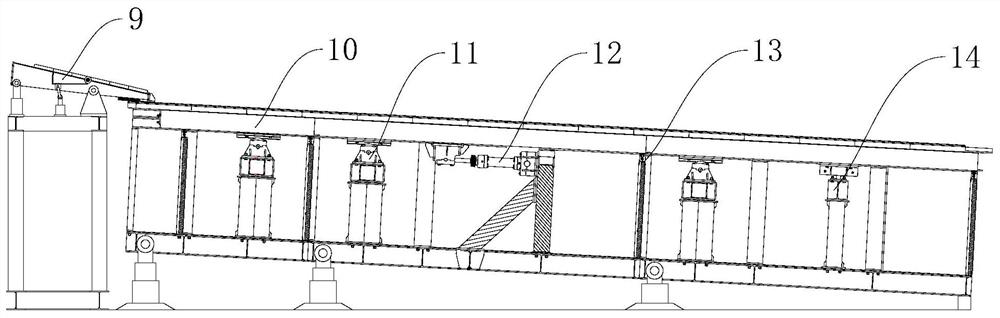

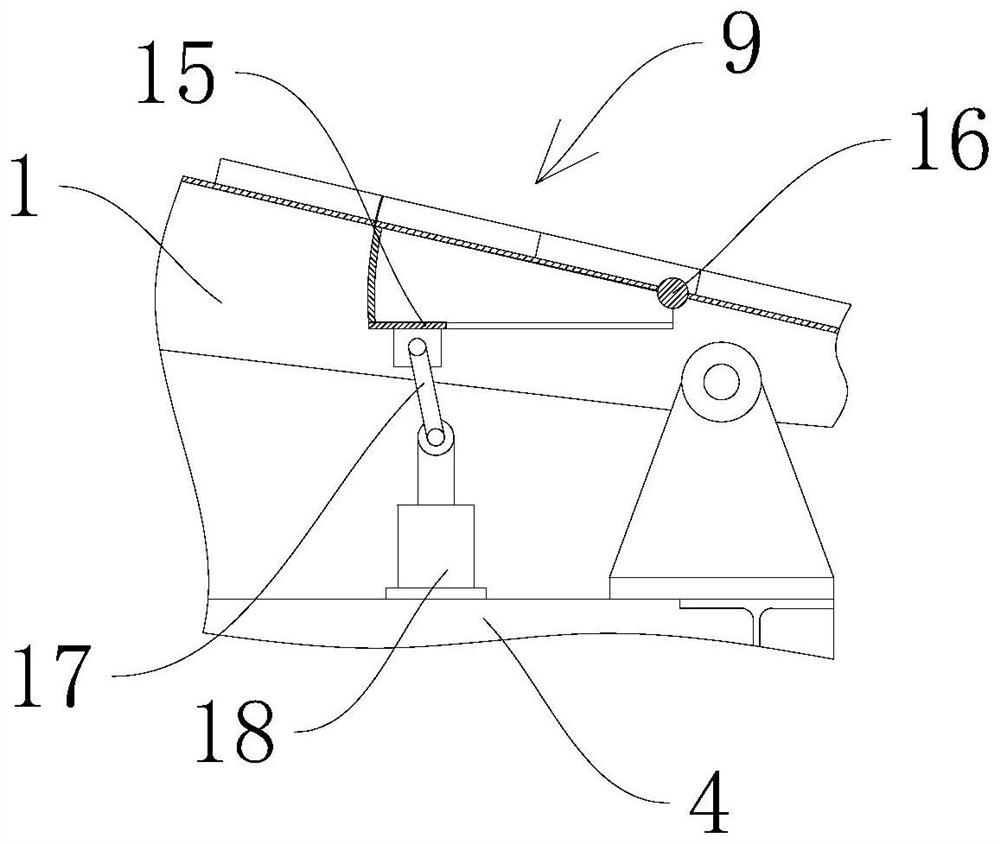

[0039] see Figure 1-7, an adjustable modular grate cooler for a lithium ore smelter, comprising an adjustable grate bed 1, a support frame 4 and a modular frame, a lifting hydraulic cylinder A3 is fixedly installed at the edge of one side of the top of the support frame 4, and the support frame 4. A support base 2 is fixedly connected to the side of the top opposite to the lifting hydraulic cylinder A3, the top of the lifting hydraulic cylinder A3 is fixedly connected to the bottom left side of the adjustable grate bed 1, and the top of the support base 2 is rotatably connected to the side wall of the adjustable grate bed 1; The top middle position of the adjustable grate bed 1 is connected with a discharge assembly 9; the modular frame includes A module frame 6, B module frame 7 and C module frame 8, A module frame 6, B module frame 7 and C module frame 8 in turn It is fixedly connected to one side of the support frame 4, and the height of the modular frame is lower than tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com