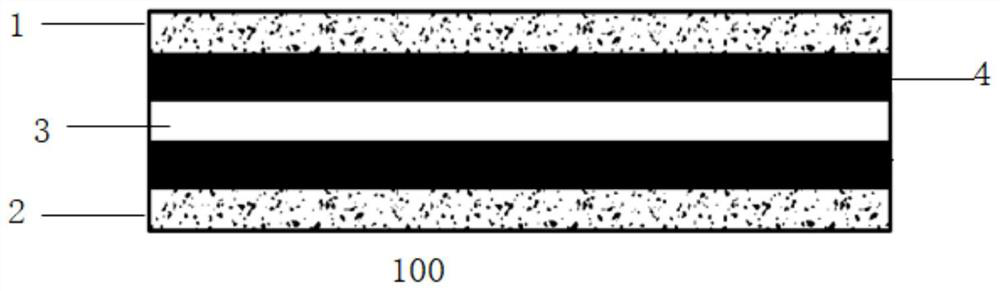

Solid-state battery and preparation method and application thereof

A solid-state battery, solid-state electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of poor cycle performance of solid-state batteries, and achieve the effect of excellent cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention has no special requirements on the preparation method of the positive electrode sheet and the negative electrode sheet, and can be prepared by methods known in the art.

[0063] The present invention has no special requirements on the preparation method of the battery core, which can be carried out by a method known in the art, for example, it can be prepared by a lamination or winding method.

[0064] In the present invention, the electrolyte is solidified during the chemical conversion process, that is, the chemical conversion conditions at least include: a vacuum degree of 0.8-2MPa, a temperature of 80-120°C, and a time of 12-30h. The inventors found that by adopting the specific embodiment in this preferred case, the prepared solid-state battery has more excellent cycle stability.

[0065] According to a particularly preferred embodiment, in step (3), the second solvent is ethanol.

[0066] Preferably, in step (3), the amount of the second sol...

Embodiment 1

[0079] This embodiment provides a method for preparing a solid-state battery, comprising the following steps:

[0080] (1) the solid electrolyte (the amount of solid electrolyte is 5g), the binder and the lithium salt are dissolved in the first solvent according to the mass ratio of 1:0.5:0.1, and the first contact mixing is carried out to obtain the first mixed solution, and Casting the first mixed solution in a polytetrafluoroethylene circular mold for drying to obtain a solid electrolyte membrane with an average thickness of 100 μm;

[0081] Wherein, the conditions of the first contact mixing are: the stirring speed is 300rpm, the temperature is room temperature, and the time is 8h;

[0082] The conditions of drying treatment are: the vacuum degree is negative pressure 100Pa, the temperature is 100℃, and the time is 24h;

[0083] (2) Stack the positive electrode sheet, the solid electrolyte membrane, and the negative electrode sheet in turn, and weld the tabs, and wind the...

Embodiment 2

[0088] This embodiment provides a method for preparing a solid-state battery, comprising the following steps:

[0089] (1) the solid electrolyte (the amount of solid electrolyte is 5g), the binder and the lithium salt are dissolved in the first solvent according to the mass ratio of 1:0.6:0.2, and the first contact mixing is carried out to obtain the first mixed solution, and Casting the first mixed solution in a polytetrafluoroethylene circular mold for drying to obtain a solid electrolyte membrane with an average thickness of 100 μm;

[0090] Wherein, the conditions of the first contact mixing are: the stirring speed is 300rpm, the temperature is room temperature, and the time is 8h;

[0091] The conditions of drying treatment are: the vacuum degree is negative pressure 300Pa, the temperature is 100℃, and the time is 24h;

[0092] (2) Stack the positive electrode sheet, the solid electrolyte membrane, and the negative electrode sheet in turn, and weld the tabs, and wind the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com