Low-carbon alkane dehydrogenation catalyst as well as preparation method and application thereof

A dehydrogenation catalyst and low-carbon alkane technology, which is applied in catalyst activation/preparation, hydrocarbons, hydrocarbons, etc., can solve the problems of poor stability of Pt-based low-carbon alkane dehydrogenation catalysts, etc., and achieve high dehydrogenation product selection. The effect of sexual and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A second aspect of the present invention provides a method for preparing a low-carbon alkane dehydrogenation catalyst, the method comprising the following steps:

[0050] (1) oxidizing carbon nanotubes with an acid solution, followed by washing and first drying to obtain a carbon nanotube carrier;

[0051] (2) The carbon nanotube support in step (1) is first impregnated with a solution containing an indium compound, and then subjected to a second impregnation with a solution containing a platinum compound, and then subjected to a second drying and reduction treatment.

[0052] The preparation method of the second aspect of the present invention can be used to prepare the low-carbon alkane dehydrogenation catalyst of the first aspect, and the definitions for the raw material carbon nanotubes are the same, which will not be repeated here.

[0053] In the present invention, step (1) is used to treat the carbon nanotubes to facilitate the loading of the platinum component a...

Embodiment 1

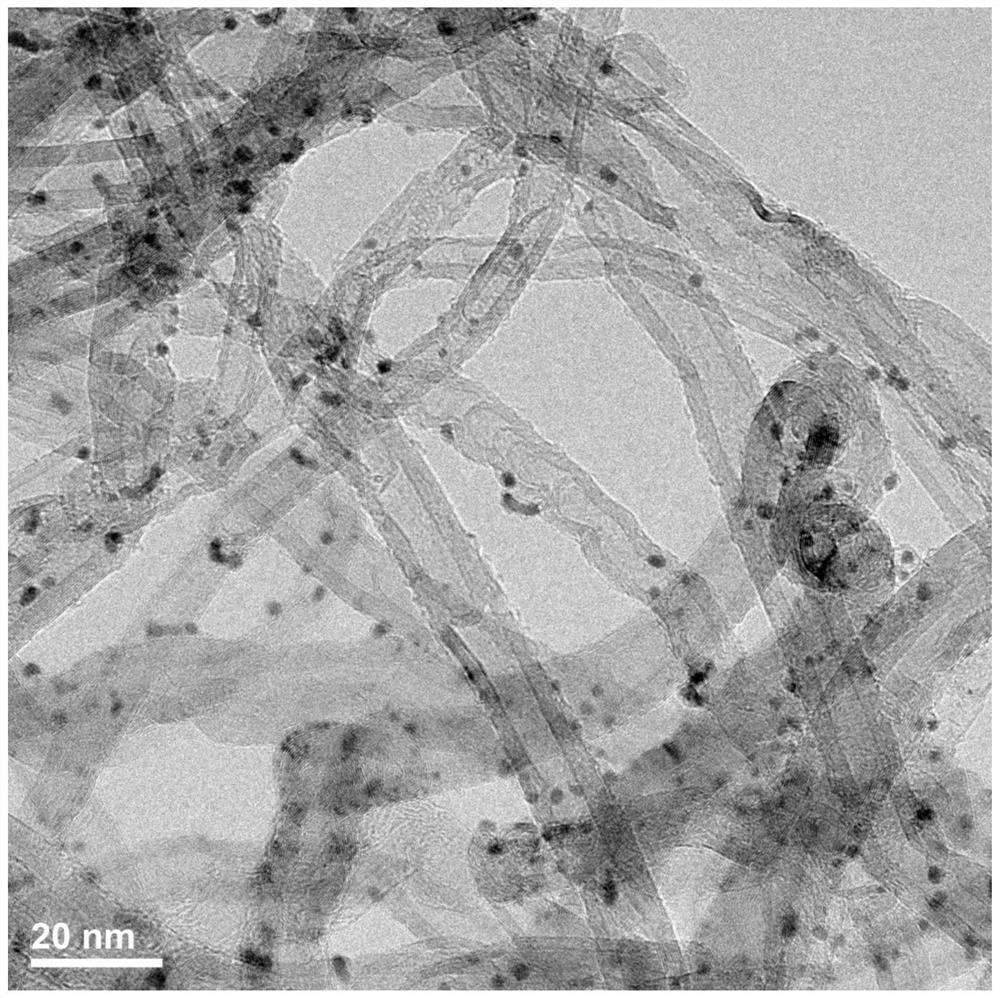

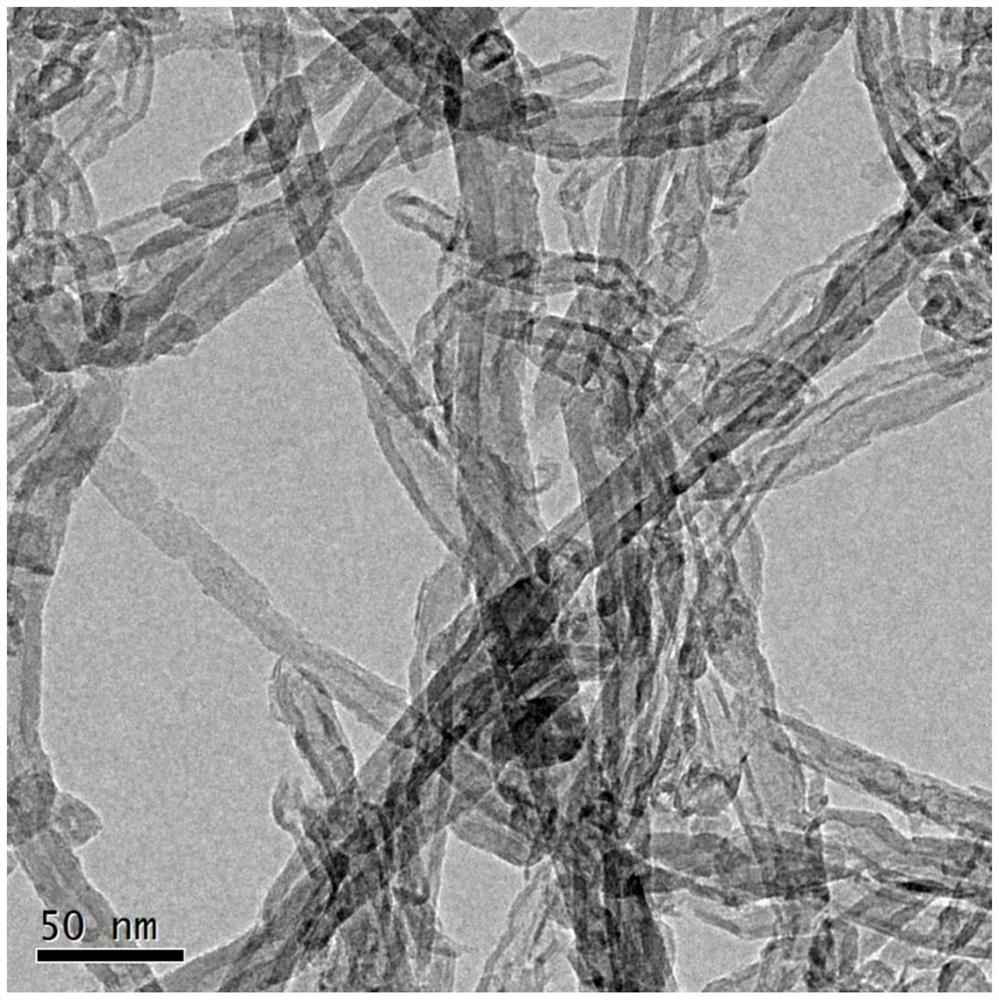

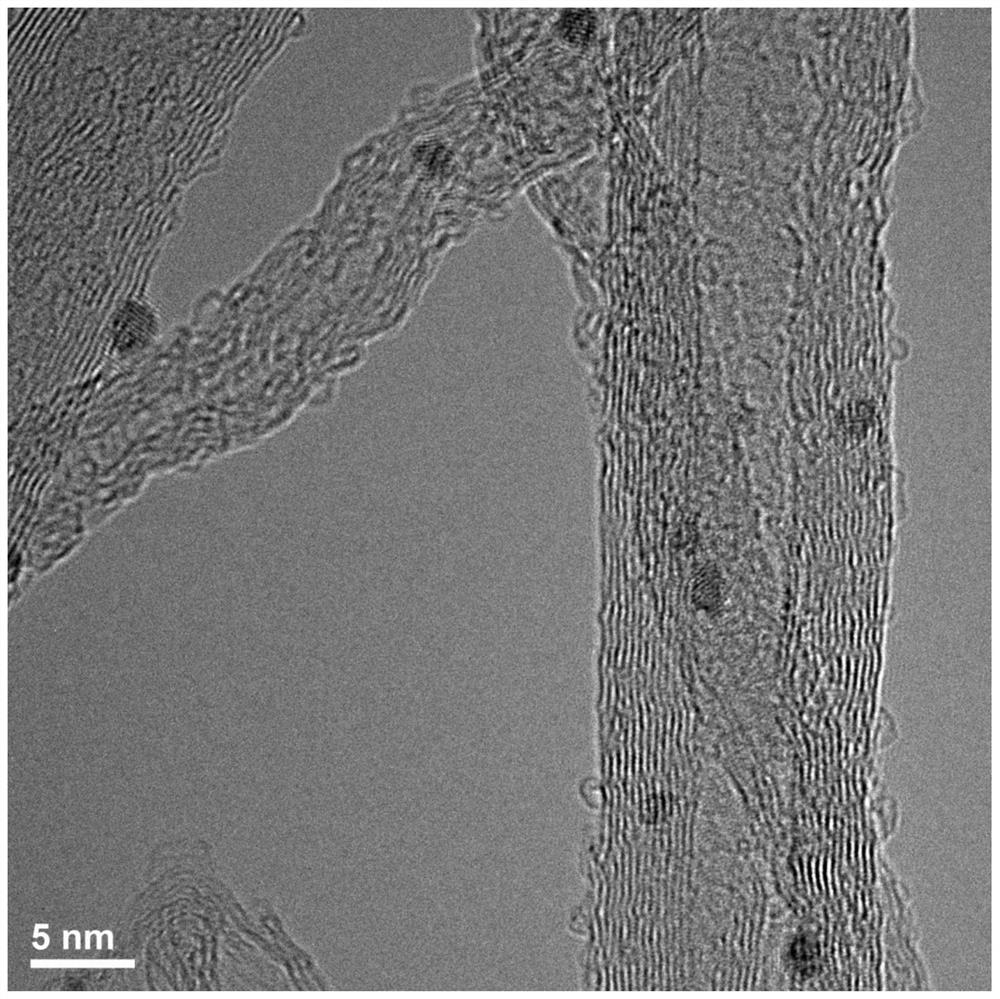

[0069] (1) Preparation of multi-walled carbon nanotube carrier

[0070] Take 2.5g of multi-walled carbon nanotubes (purity > 98wt.%, ash 3 After immersion and oxidation treatment at 140 °C for 14 h, the solids were washed with deionized water and dried in air at 110 °C for 12 h to obtain multi-walled carbon nanotube-supported CNTs.

[0071] (2) Preparation of catalyst

[0072] Take 0.3 g of the multi-walled carbon nanotube carrier CNTs prepared in step (1), 3 mL of an ethanol solution of indium nitrate with a concentration of 3 mg / mL in In, and 3 mL of absolute ethanol in a 50 mL beaker, and after stirring at 25 °C for 0.5 h, Ultrasonic treatment was performed at 25 °C for 3 h, and then stirred for 0.5 h; then 3 mL of an ethanol solution of chloroplatinic acid with a concentration of 5 mg / mL in terms of Pt was added, and the mixture was stirred at 100 °C for 20 min. Then dried at 110 °C for 24 h, at 580 °C in H 2 Reduction in 1h to obtain catalyst C1.

Embodiment 2

[0074] The catalyst was prepared according to the method of Example 1, except that in step (2), the ethanol solution of chloroplatinic acid with a concentration of 1 mg / mL in terms of Pt was used to prepare catalyst C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com