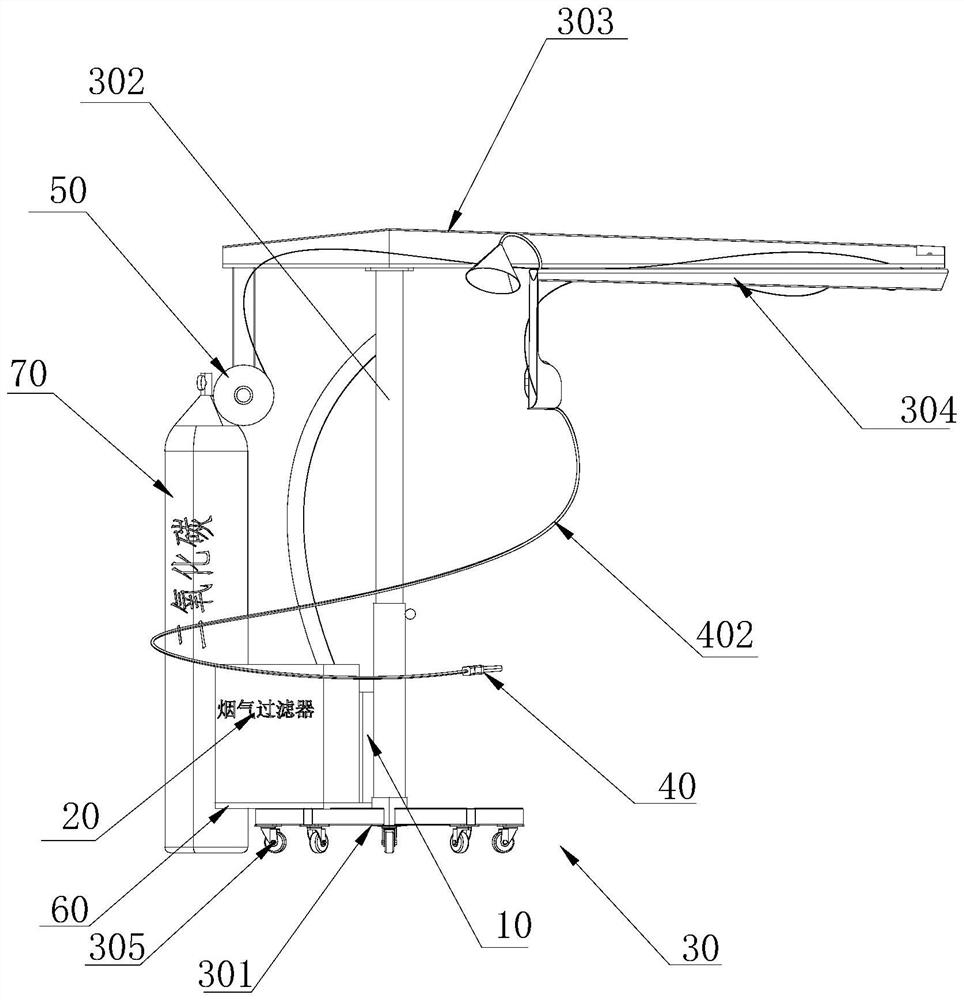

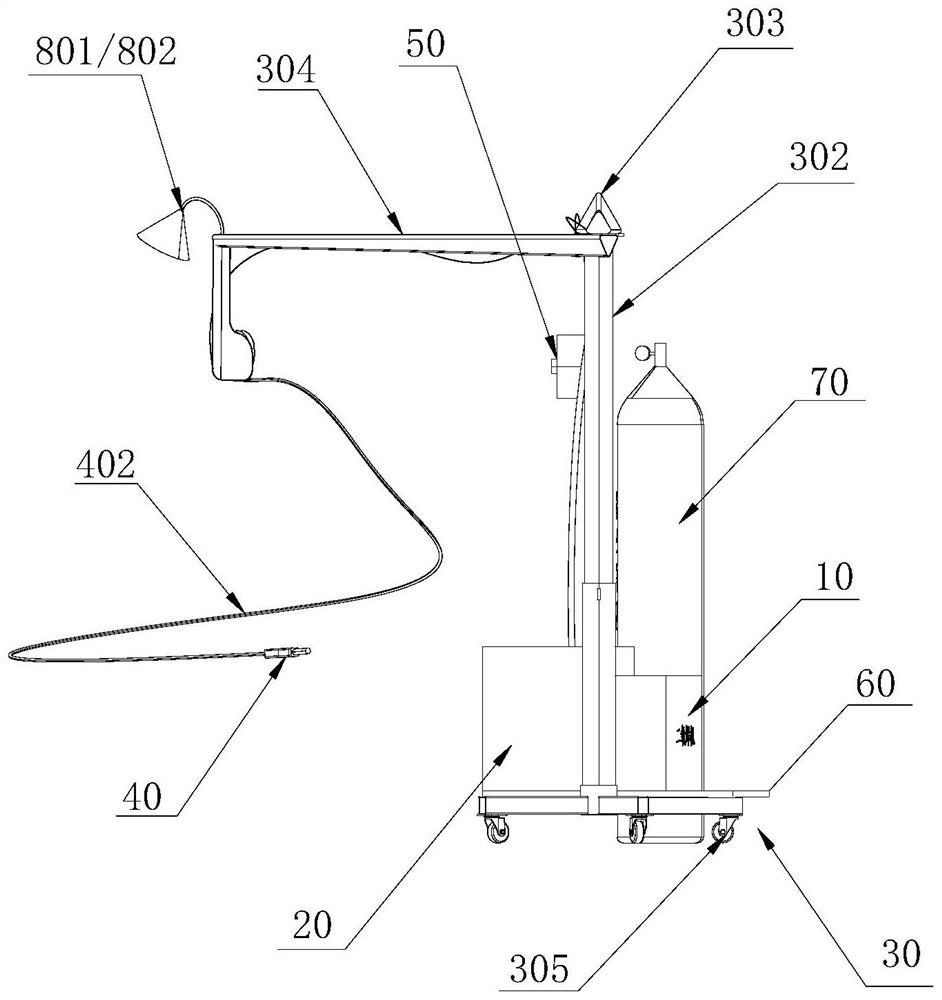

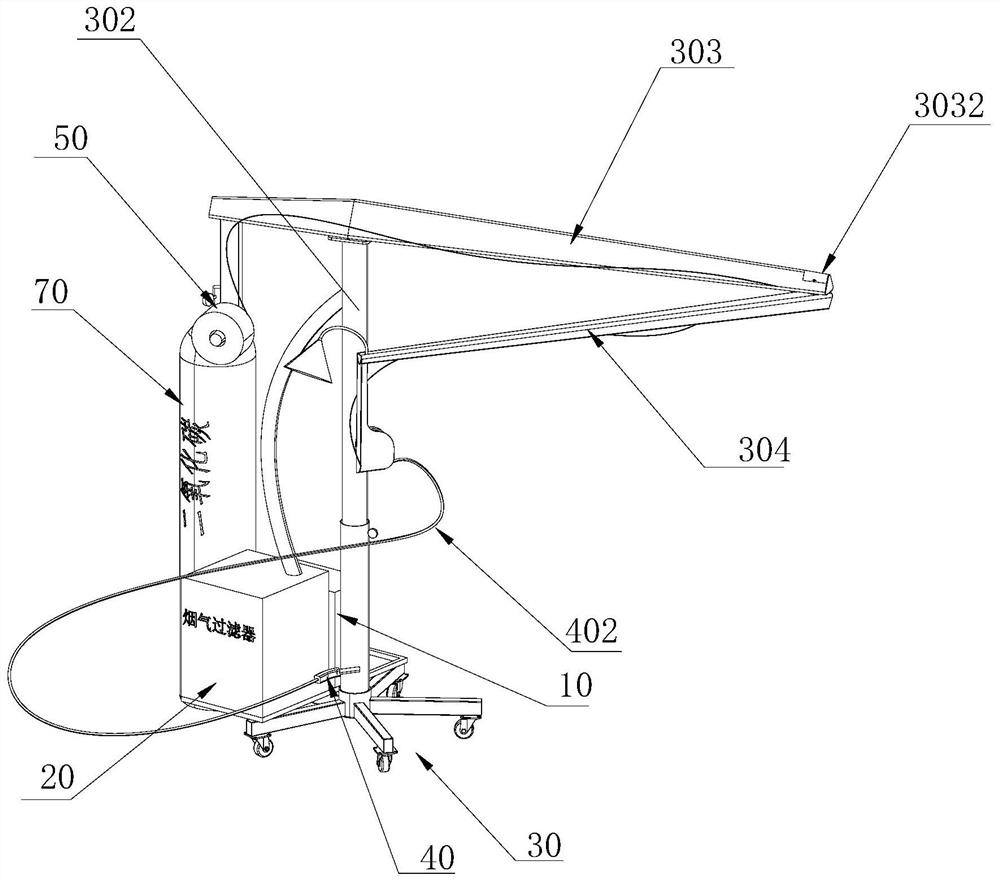

Self-adaptive cantilever type shielded welding machine assembly

A cantilever, self-adaptive technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing the work quality of welding robots, threats to the health of operators, and inability to deal with flue gas, and achieves improvement. Welding feel, improving heat dissipation, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] Example 2, see Figure 14 ; On the basis of Example 1, when welding encounters a complex welding surface, if a wind-guiding shroud with supporting strength is used, the welding will be affected. At this time, the air-guiding shroud can adopt the following technical scheme: The wind deflector 406 includes a support sleeve 406-1, which is used for supporting the flexible shielding cover and connecting the air duct. The flexible shielding cover has a certain deformation ability at this time. mesh cloth, the flexible shielding cover is fixedly connected to the support sleeve.

Embodiment 3

[0043] Example 3, see Figure 15 and Figure 16 In this embodiment, the welding torch includes a welding torch handle 401, a welding torch cable 402 connected to one end of the welding torch handle, and a welding assembly 403 installed on the welding torch handle and connected to the welding torch cable; the welding assembly includes a gooseneck elbow assembly extending out of the welding torch handle, The conductive connection assembly connecting the gooseneck elbow assembly, the conductive connection assembly is connected to the welding torch cable, and the control switch 404 is also installed on the welding torch handle; The two welding torch handle bodies are provided with support rib plates for supporting the conductive connection assembly, and the support rib plates are provided with air passages along the length direction of the welding torch handle; One end of the draft pipe is connected to the welding torch handle, and the other end of the draft pipe is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com