Ultralow-temperature drilling fluid base fluid as well as preparation method and application thereof

A drilling fluid and ultra-low temperature technology, applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve the problems of poor low temperature resistance and high irritation, reduce the surface area and pore size, and reduce the preparation method Simple, non-irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

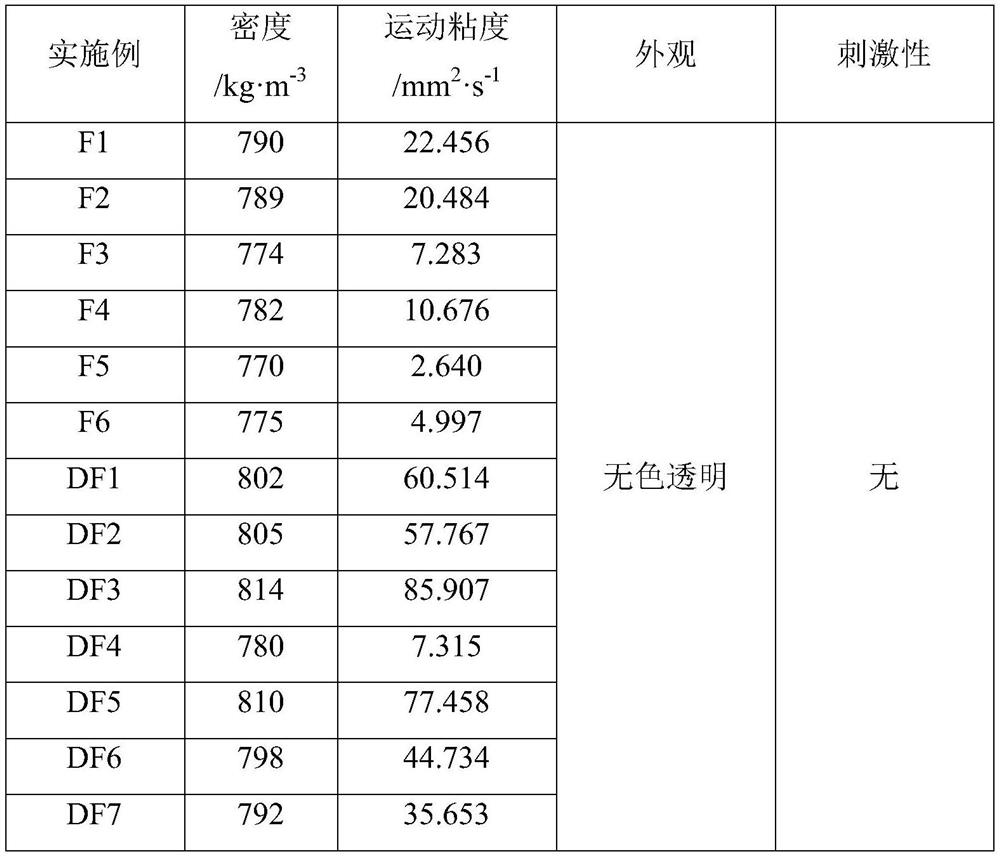

Examples

Embodiment 1

[0028] A preparation method of ultra-low temperature drilling fluid base fluid, comprising the steps of:

[0029] 1) Dissolve the promoter zinc chloride in ethanol at room temperature (the mass ratio of the promoter zinc chloride to the ethanol volume is 0.05:1 g / mL), then add the main catalyst montmorillonite K-10, montmorillonite K The mass ratio of -10 to zinc chloride is 10:3. After stirring evenly, the ethanol is distilled off under reduced pressure, and the catalyst mixture is obtained after activating it at 120 °C for 4 hours;

[0030] 2) Add the catalyst mixture and hexene with a mass ratio of 0.05:1 into the high temperature and high pressure reaction kettle, seal it, add the pressure of 1.5 MPa and then heat up to 160 ° C, and react for 3 hours to obtain a post-reaction solution;

[0031] 3) Filtering the solution after the reaction, and distilling under reduced pressure to remove unreacted monomers to obtain an ultra-low temperature drilling fluid base fluid for pol...

Embodiment 2

[0033] A preparation method of ultra-low temperature drilling fluid base fluid, comprising the steps of:

[0034] 1) Dissolve the promoter zinc chloride in ethanol at room temperature (the mass ratio of the promoter zinc chloride to the ethanol volume is 0.05:1 g / mL), then add the main catalyst montmorillonite K-10, montmorillonite K The mass ratio of -10 to zinc chloride is 2.5:1. After stirring evenly, the ethanol is distilled off under reduced pressure, and the catalyst mixture is obtained after activating it at 120 °C for 4 hours;

[0035] 2) Add the catalyst mixture and hexene with a mass ratio of 0.05:1 into the high temperature and high pressure reaction kettle, seal it, load the pressure of 1.6 MPa and then heat up to 160 ° C, and react for 3 hours to obtain a post-reaction solution;

[0036] 3) Filtering the solution after the reaction, and distilling under reduced pressure to remove unreacted monomers to obtain an ultra-low temperature drilling fluid base fluid for p...

Embodiment 3

[0038] A preparation method of ultra-low temperature drilling fluid base fluid, comprising the steps of:

[0039] 1) Dissolve the promoter zinc chloride in ethanol at room temperature (the mass ratio of the promoter zinc chloride to the ethanol volume is 0.05:1 g / mL), then add the main catalyst montmorillonite K-10, montmorillonite K The mass ratio of -10 to zinc chloride is 20:9. After stirring evenly, the ethanol is distilled off under reduced pressure, and the catalyst mixture is obtained after activating it at 120 °C for 4 hours;

[0040] 2) Add the catalyst mixture and hexene with a mass ratio of 0.04:1 into the high-temperature and high-pressure reaction kettle, seal it, add the pressure of 1.7 MPa and then heat up to 160° C. After reacting for 2 hours, a post-reaction solution is obtained;

[0041] 3) Filtering the solution after the reaction, and distilling under reduced pressure to remove unreacted monomers to obtain an ultra-low temperature drilling fluid base fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com