Lightweight FRP water conveying pipe and processing technology thereof

A processing technology and water pipe technology, which is applied in the direction of general water supply saving, pipes, rigid pipes, etc., can solve the problems of poor synergy, strong vibration of water pipes, and short service life of pipes, so as to reduce damage and enhance bending resistance Rigidity, the effect of enhancing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

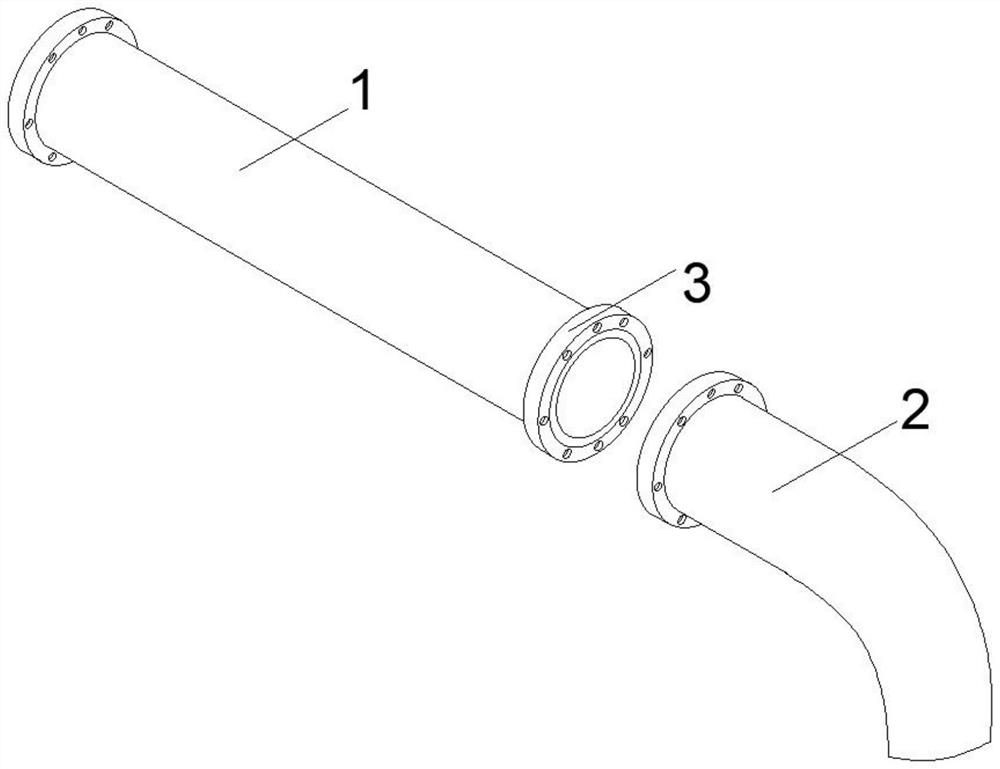

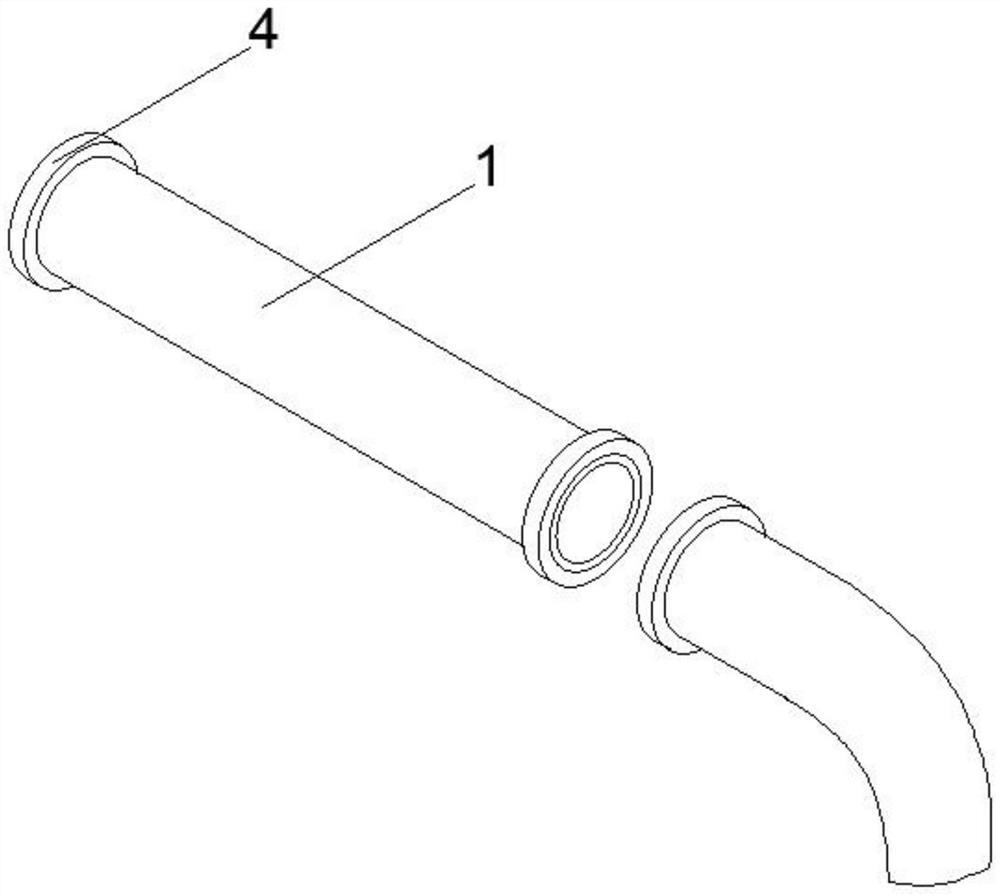

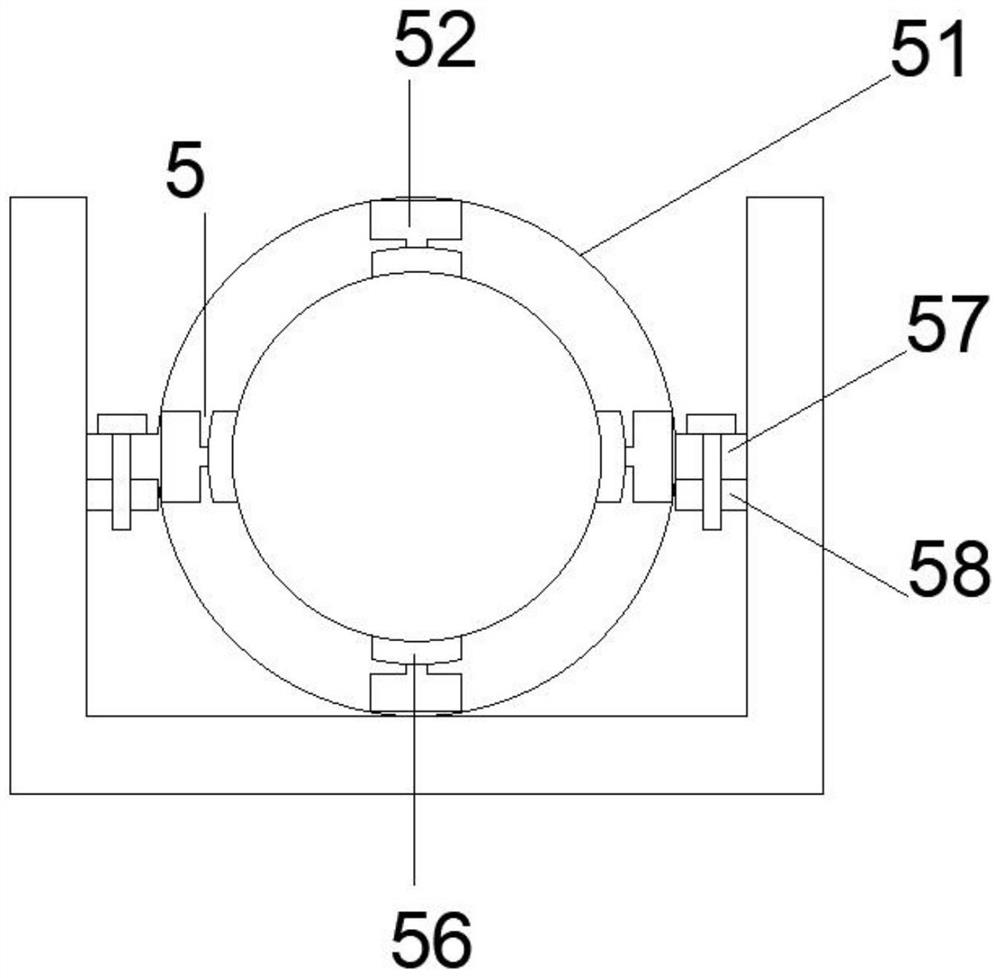

[0026] A lightweight FRP water delivery pipe, the water delivery pipe comprises a water delivery straight pipe 1 and a water delivery elbow 2, and the water delivery straight pipe 1 and the water delivery elbow 2 are connected by a FRP flange 3 or a FRP hoop 4, and the water delivery is straight. The pipe 1 and the water delivery elbow 2 are both wound with resin pre-impregnated fiber reinforced composite materials. The straight water delivery pipe 1 is provided with a plurality of buffer mechanisms 5 in an array, and the plurality of buffer mechanisms 5 can be detachably connected to the pipeline.

[0027] The resin pre-impregnated fiber reinforced composite material is resin pre-impregnated pultruded sheet or resin pre-impregnated fiber yarn, and the resin of the resin pre-impregnated fiber reinforced composite material is unsaturated resin, vinyl resin, epoxy resin o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com