Method and device for online measurement of total iron in water vapor of power station

A measurement method and water vapor technology, applied in the field of test and detection, can solve the problems of energy saving and consumption reduction of unfavorable power stations, adding a lot of ammonia water, and taking a long time to achieve the effect of reducing measurement steps and adding amount of chemicals, and achieving a high degree of intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] refer to figure 1 , This embodiment provides an on-line measurement method for total iron in water vapor in a power station, which can measure the total iron content of 0.5-1000 μg / L, wherein the method includes the following steps:

[0040] 1) Continue to inject the water sample containing colloidal iron into the overflow cup 1;

[0041] Among them, the main form of iron in water samples is colloidal iron.

[0042] 2) After the water sample flows out from the overflow cup 1, it flows into the No. 1 three-way valve 3 under the pressure of the pump 2, and at the same time, a catalytic agent is added to the No. 1 three-way valve 3 to mix with the water sample;

[0043] Specifically, the catalyst includes persulfate as (NH 4 ) 2 S 2 O 8 , NH 4 Ac, NH 4 NO 3 , first-grade reagent water, and (NH 4 ) 2 S 2 O 8 : NH 4 Ac:NH 4 NO 3 : The mass percentage of the first-grade reagent water is 4-5:2-5:4-10:80-90, and its mass percentage is preferably 4:2:4:90.

[004...

Embodiment 2

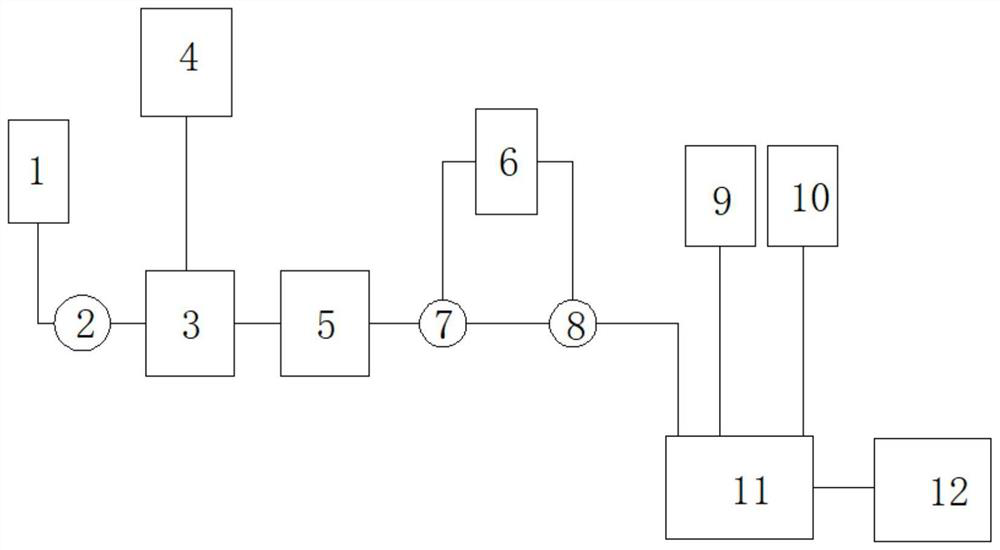

[0062] This embodiment provides an on-line measurement device for all iron in water vapor in a power station, including an overflow cup 1, a pump 2, a No. 1 three-way valve 3, an ultraviolet light oxidizer 5, a No. 2 three-way valve 7, a No. The three-way valve 8 and the optical sensing system 11 also include a catalytic agent storage tank 4 in communication with the No. 1 three-way valve 3, a concentration system 6 in communication with the No. 2 three-way valve 7 and the No. 3 three-way valve 8, respectively, and The medicine A storage tank 9 communicated with the optical sensing system 11 , the medicine B storage tank 10 communicated with the optical sensing system 11 , and the data processing system 12 signally connected with the optical sensing system 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com