Rapid reflector system based on transmissive application of eddy current sensor

A technology of eddy current sensors and mirrors, which is applied in the direction of instruments, installation, optics, etc., can solve the problems of affecting the transmission function of the working mirror body, heavy weight and large volume of shafting components, etc., and achieve increased transmission function and high coaxiality , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

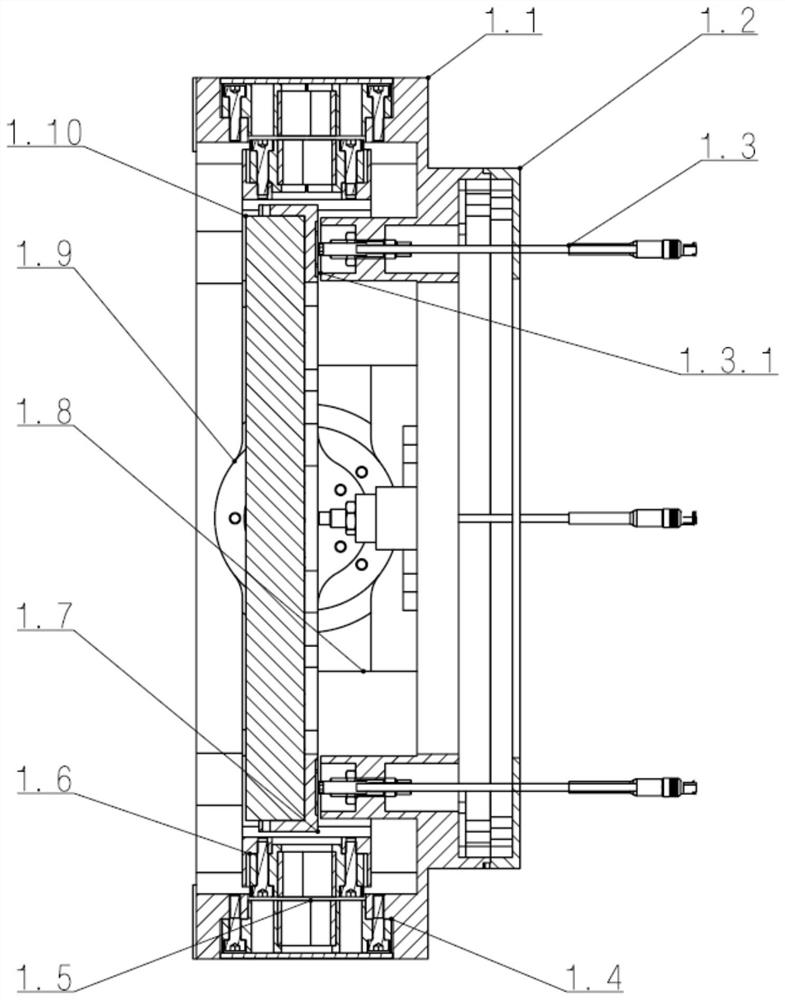

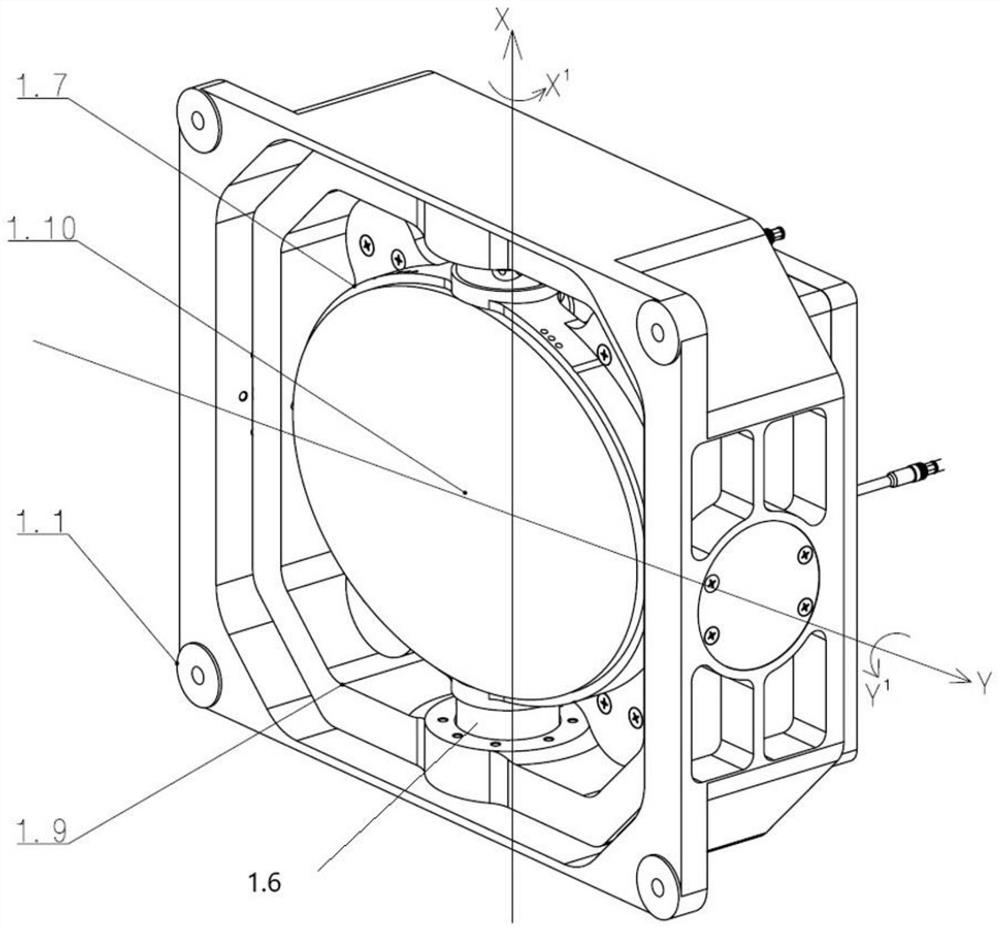

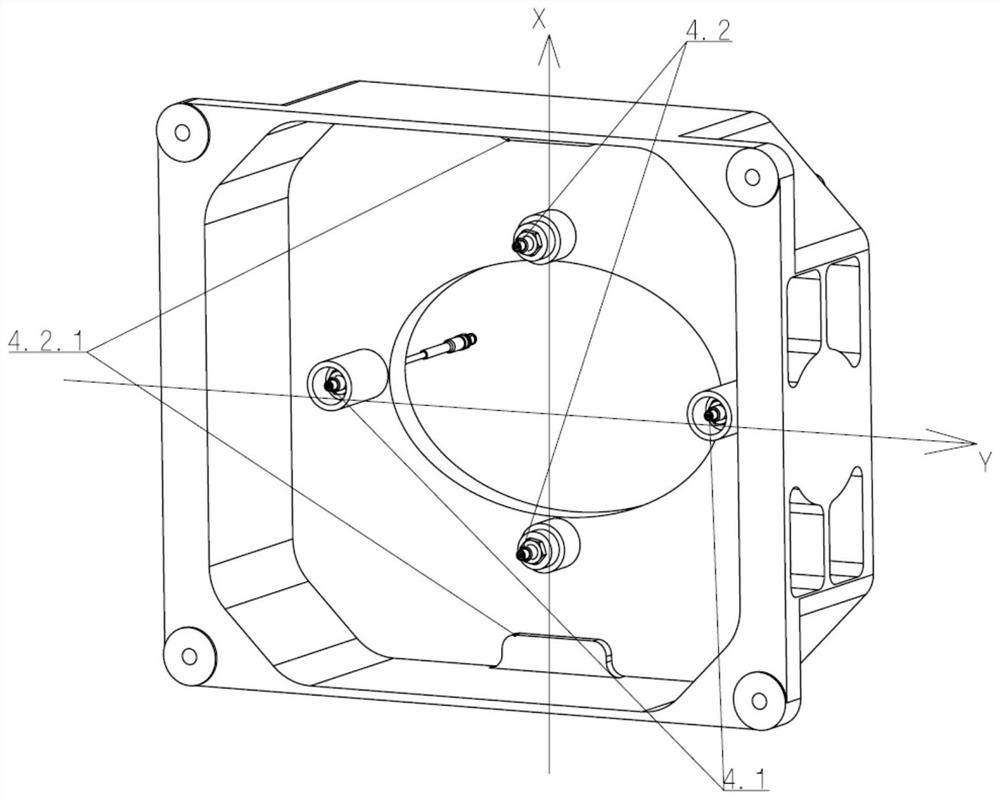

[0059] The embodiment of the present invention discloses a fast mirror system. The fast mirror system adopts a flexible hinge as a shaft system for rotary motion, a voice coil motor as a driving component, and an eddy current sensor as an angle information acquisition unit, so as to realize the rapid reflection mirror. Two-dimensional rotation function. It has the characteristics of small size, high bandwidth and high precision. It is outstanding that this type of fast mirror system can realize the ability of optical path reflection, transmission and stabilization of optical path at the same time.

[0060] Below in conjunction with the accompanying drawings, the embodiments of the present invention will be described to give a detailed and clear introduction to the actual design of the present invention. Obviously, the described embodiments can only illustrate the design concept of the present invention from a part, and cannot cover all the embodiments. Based on the embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com