Leveling and polishing device and method using femtosecond pulse laser

A femtosecond pulse and polishing device technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., to improve surface roughness, reduce processing errors, and maximize output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

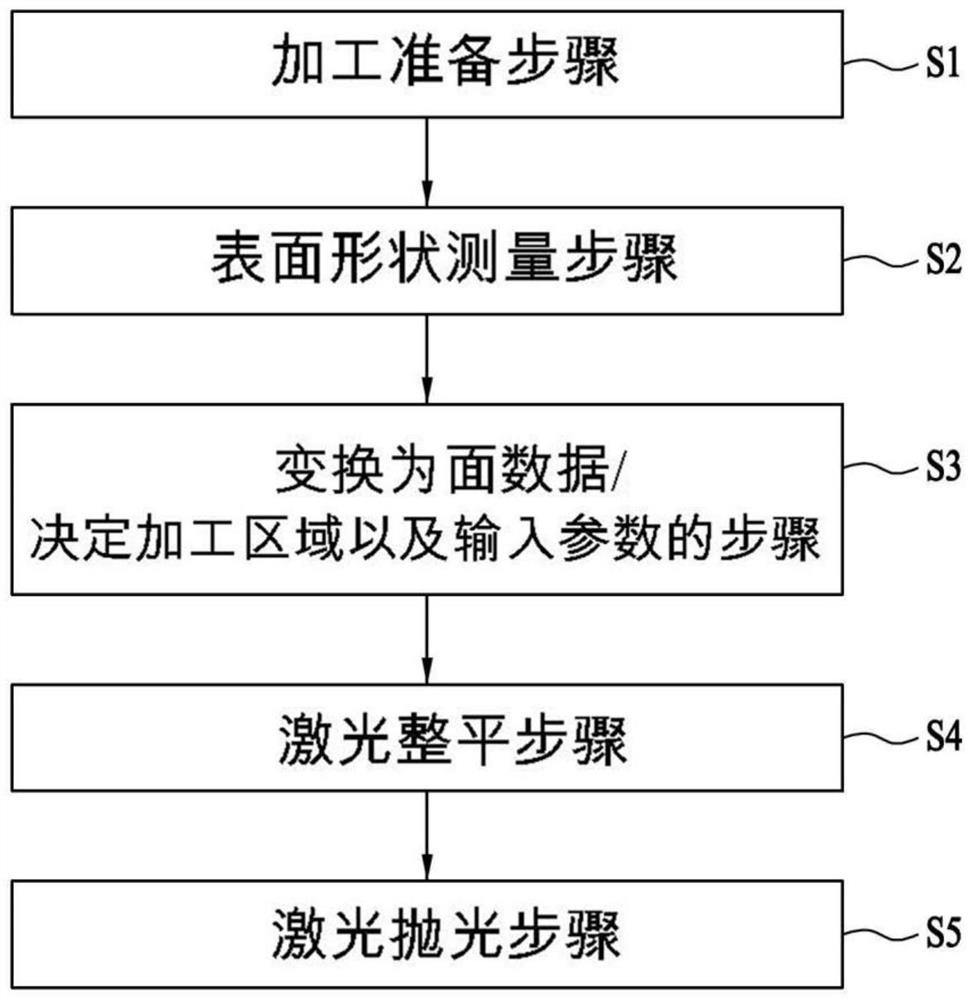

[0051] In the following, the invention will be explained in more detail by means of preferred embodiments according to the accompanying drawings.

[0052] It should be clear that planning as used in the present invention means a process of making a macro profile highly flat, which is an inventive term made by the applicant to distinguish it from a polishing process, and is used as the same as reducing The Ra value and the Ry value of the roughness in the microscopic angle have different meanings for polishing.

[0053] Generally, when viewed on the basis of the precision of precision grinding, the leveling process of the present invention has a processing degree of about 10 μm, and the polishing process has a processing degree of about 0.8 μm, and the two processes are strictly distinguished and used.

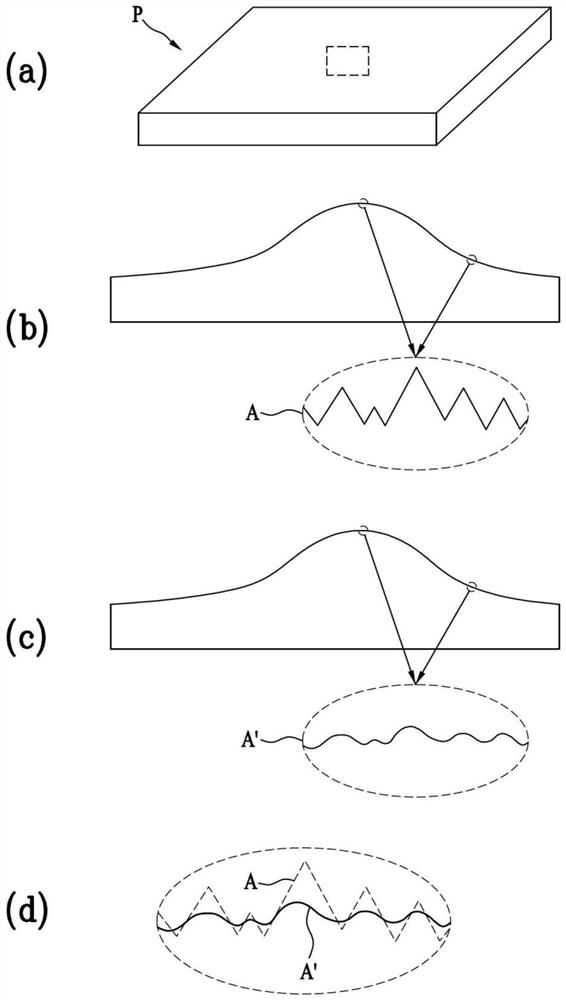

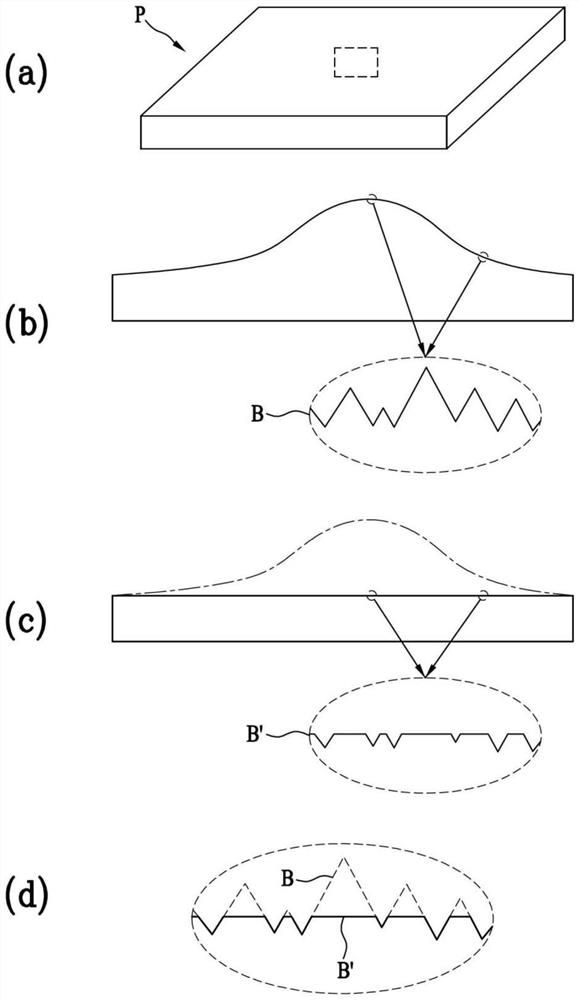

[0054] figure 1 is a schematic diagram showing the state of the material section before and after the process by the conventional laser polishing work, and figure 2 The stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com