High-strength, anti-freezing and transparent conductive PVA/quaternary ammonium salt elastomer

A quaternary ammonium salt, high-strength technology, used in electric/magnetic solid deformation measurement, electromagnetic measurement device, bulk chemical production, etc. The effect of excellent optical clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

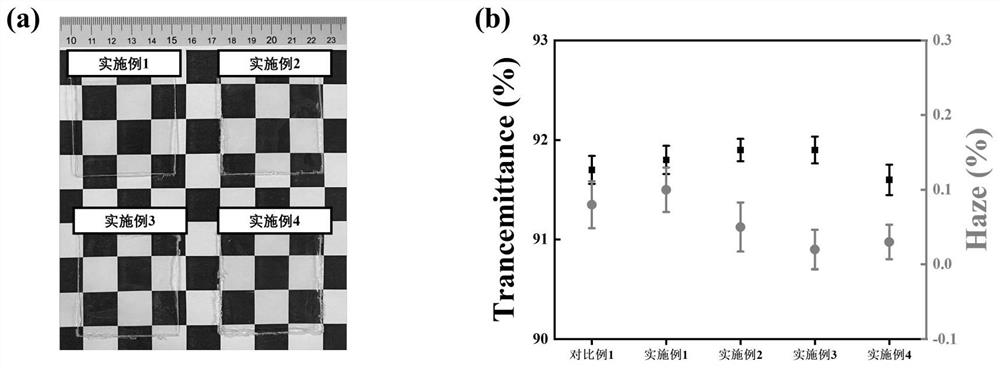

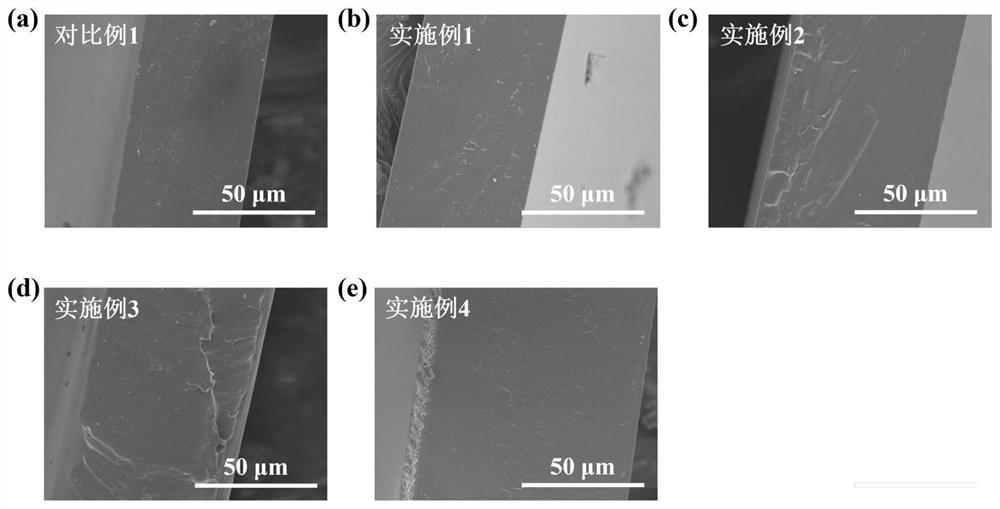

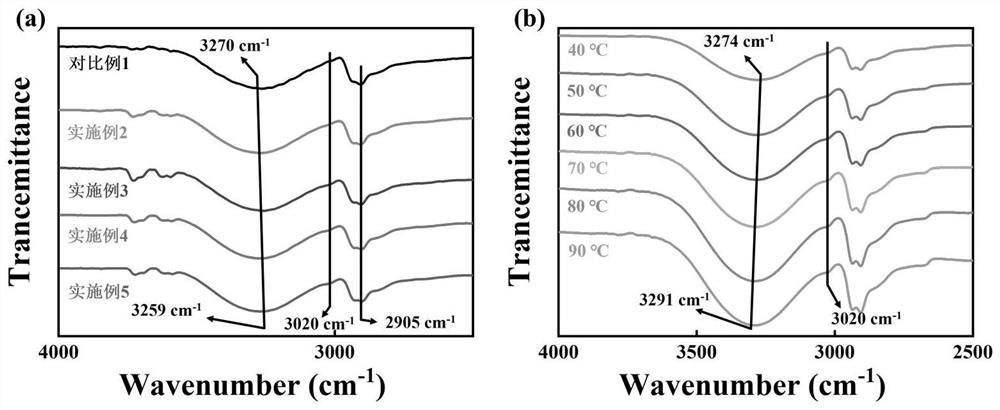

Examples

preparation example Construction

[0043] On the other hand, the preparation method of high-strength, frost-resistant and transparent conductive PVA / quaternary ammonium salt elastomer comprises the following steps:

[0044] Step (1) adding PVA and quaternary ammonium salt into the reactor according to a certain proportion to carry out solution blending; wherein the mass ratio of quaternary ammonium salt and PVA is 15-30:100. The solvent is water. The temperature was 80°C.

[0045] Step (2) The above solution blended by the solution is filmed, dried to remove the solvent to obtain a PVA / quaternary ammonium salt elastomer, and finally the performance is characterized.

Embodiment 1

[0050] Step (1) First, 10g of PVA and 1g of ChCl were added to the reaction kettle, the temperature was 80°C, and the solution was mixed for 6h;

[0051] Step (2) Cool the solution to room temperature, pour it into a PTFE mold for film laying, evaporate the solvent on the obtained film, and vacuum dry for 24 hours. Note 15wt%-PVA elastomer.

Embodiment 2

[0053] Step (1) First, 10g of PVA and 1g of ChCl were added to the reaction kettle, the temperature was 80°C, and the solution was mixed for 6h;

[0054] Step (2) Cool the solution to room temperature, pour it into a PTFE mold for film laying, evaporate the solvent on the obtained film, and vacuum dry for 24 hours. Note 20wt%-PVA elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com