High-uniformity metallization method and equipment for large-tow fiber and large-tow fiber

A large tow and metallization technology, applied in the field of large tow fibers, can solve the problems of uneven metallization layer of large tow fibers, black cores of large tow fibers, affecting the use effect, etc., to avoid uneven diffusion and ensure The effect of uniformity and technical solution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

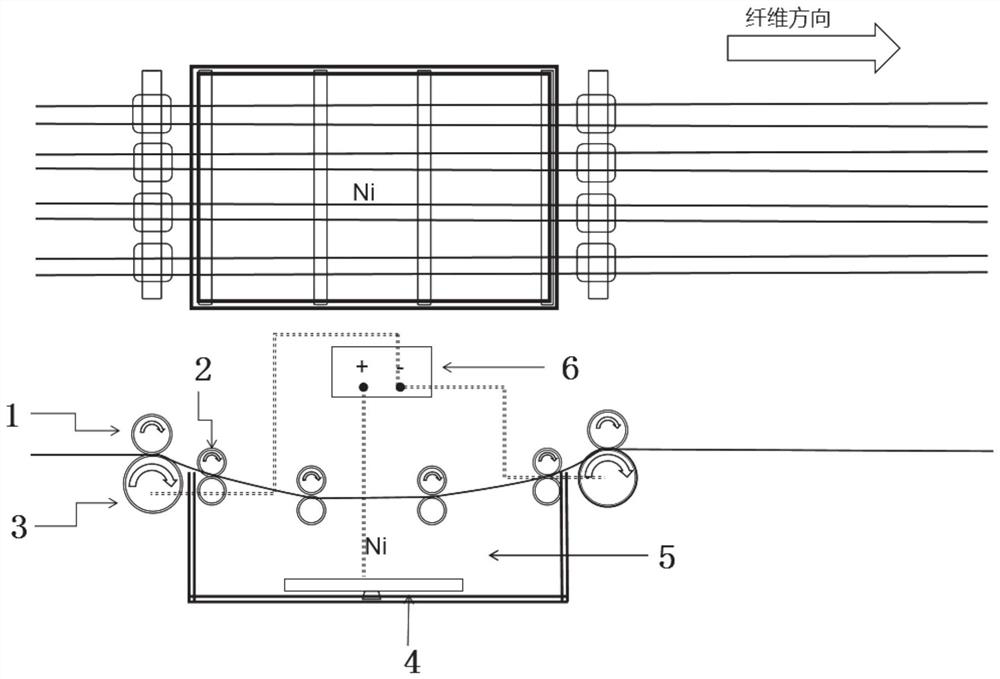

[0065] This embodiment provides a highly uniform metallization method of 12k carbon fiber, using such as figure 1 Equipment shown, specifically:

[0066] The electroplating solution in the electroplating tank 5 is a commercially available nickel plating solution, and it consists of: nickel chloride, hydrochloric acid, pure water, activator;

[0067] The above-mentioned carbon fibers that have undergone high-temperature degumming pretreatment are continuously entered into the electroplating tank 5, and the carbon fibers are in contact with the soft guide rollers 1 and the electrode guide rollers 2 on both sides of the electroplating tank 5, and are indirectly electrically connected to the negative electrode of the electroplating power supply 6. The carbon fiber is used as a cathode to deposit a metal nickel layer in the electroplating solution, and the current density is 2A / dm2;

[0068] In the electroplating solution, the carbon fibers are continuously passed through 4 sets ...

Embodiment 2

[0072] This embodiment provides a highly uniform metallization method of 12k carbon fiber, using such as figure 1 The equipment shown, the process is basically the same as the embodiment 1, the only difference is:

[0073] The first group and the last group of flattening guide rollers 3 are not arranged at the edge of the electroplating tank 5 , but are arranged in the middle section away from the edge of the electroplating tank 5 together with the middle flattening guide roller 3 .

[0074] The high uniformity metallized large tow fibers prepared in this example have the same properties as those in Example 1. However, in this example, the loss rate of the electroplating solution is 8 L / day, which is significantly greater than that in Example 1.

Embodiment 3

[0076] This embodiment provides a high uniformity metallization method of 12K PE fiber, using such as figure 1 For the equipment shown, the process is basically the same as that of Example 1.

[0077] The metallized multifilament tow PE fibers prepared in this example also have high uniformity and flatness of the coating, and have no "black heart" phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com