Activator, preparation method and preparation method of carbon fiber composite material

An activation solution and carbon fiber technology, applied in the field of chemical plating, can solve the problems of carbon fiber agglomeration, cumbersome activation process steps, low stability, etc., and achieve the effects of high plating rate, good activation effect and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is the preparation of carbon fiber composite material, comprising the following steps:

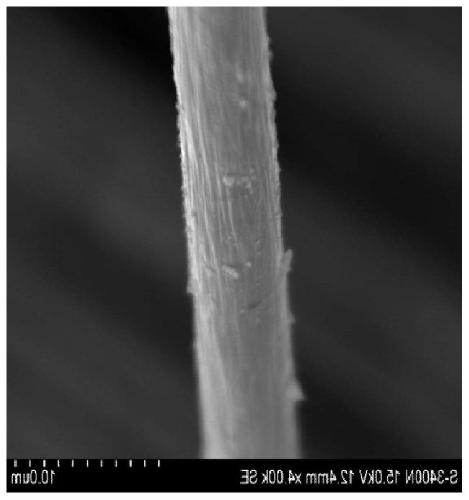

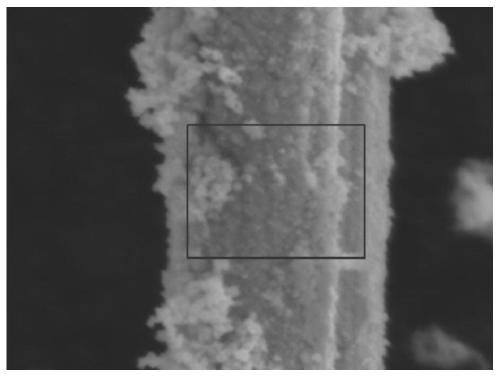

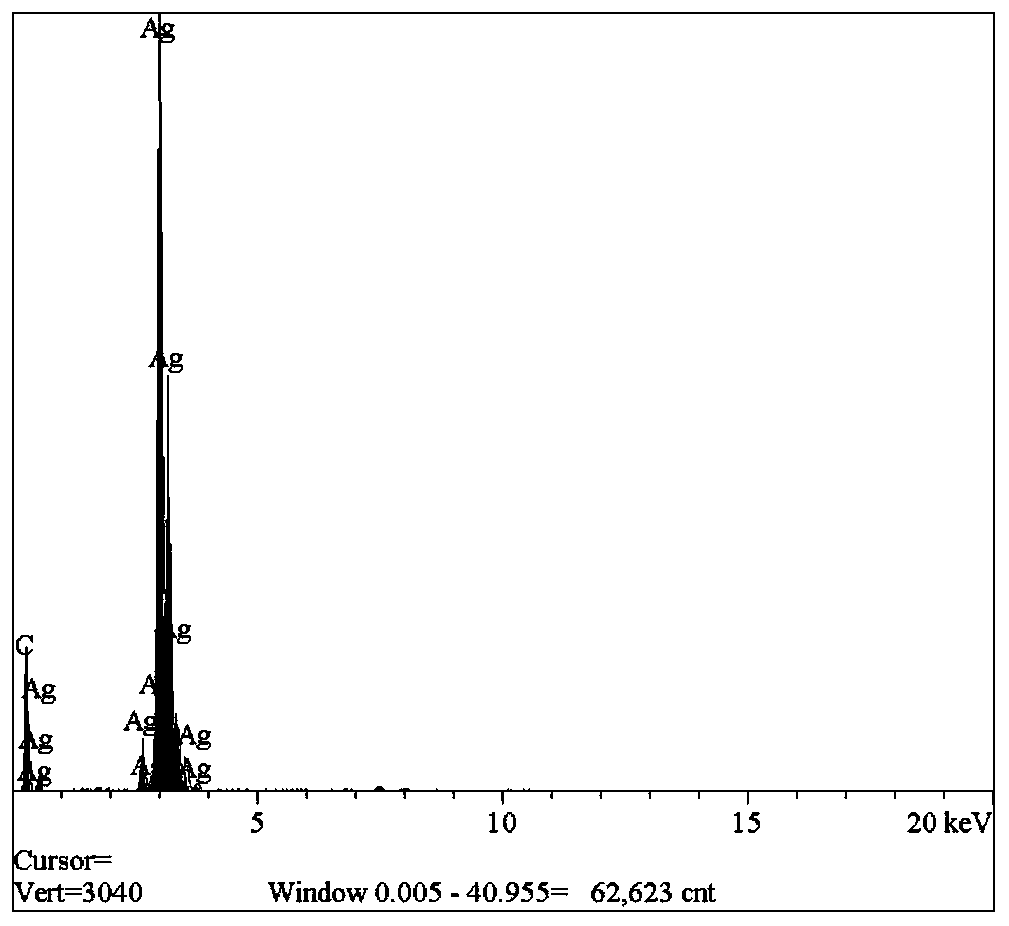

[0049] (1) Pretreatment, first place the carbon fiber in a box-type resistance furnace for high-temperature burning, and remove the glue on the surface of the carbon fiber; place the carbon fiber after high-temperature degumming in an ultrasonic cleaner for dispersion, so as to disperse the carbon fiber into a single Silk state; the dispersed carbon fiber is placed in nitric acid solution for roughening, so that the surface of the carbon fiber is etched into a groove shape, and the surface of the carbon fiber is changed from hydrophobic to hydrophilic; finally, the roughened carbon fiber is placed in hydrogen Neutralize in a sodium oxide solution to remove the residual acidic substances on the surface of the carbon fiber, and then clean the carbon fiber to neutral to complete the pretreatment.

[0050] (2) Activation, the pretreated carbon fiber is immersed in the ac...

Embodiment 2

[0055] This embodiment is the preparation of carbon fiber composite material, comprising the following steps:

[0056] (1) Pretreatment, first place the carbon fiber in a box-type resistance furnace for high-temperature burning, and remove the glue on the surface of the carbon fiber; place the carbon fiber after high-temperature degumming in an ultrasonic cleaner for dispersion, so as to disperse the carbon fiber into a single Silk state; the dispersed carbon fiber is placed in nitric acid solution for roughening, so that the surface of the carbon fiber is etched into a groove shape, and the surface of the carbon fiber is changed from hydrophobic to hydrophilic; finally, the roughened carbon fiber is placed in hydrogen Neutralize in a sodium oxide solution to remove the residual acidic substances on the surface of the carbon fiber, and then clean the carbon fiber to neutral to complete the pretreatment.

[0057] (2) Activation, immerse the pretreated carbon fiber in the activa...

Embodiment 3

[0062] This embodiment is the preparation of carbon fiber composite material, comprising the following steps:

[0063] (1) Pretreatment, first place the carbon fiber in a box-type resistance furnace for high-temperature burning, and remove the glue on the surface of the carbon fiber; place the carbon fiber after high-temperature degumming in an ultrasonic cleaner for dispersion, so as to disperse the carbon fiber into a single Silk state; the dispersed carbon fiber is placed in nitric acid solution for roughening, so that the surface of the carbon fiber is etched into a groove shape, and the surface of the carbon fiber is changed from hydrophobic to hydrophilic; finally, the roughened carbon fiber is placed in hydrogen Neutralize in a sodium oxide solution to remove the residual acidic substances on the surface of the carbon fiber, and then clean the carbon fiber to neutral to complete the pretreatment.

[0064] (1) Activation, immerse the pretreated carbon fiber in the activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com