Abrasion-remedied wave-transparent silicon nitride fiber oiling agent and preparation method thereof

A technology of silicon nitride fiber and oil agent, which is applied in fiber treatment, general water supply saving, textile and paper making, etc. It can solve the problem of damaging the performance of ceramic matrix composite materials, detrimental to the high temperature performance of fibers, and the failure of fibers to meet the requirements of use and other problems, to achieve good hydrophilicity and reactivity, improve the chemical bonding force of fibers, and achieve the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

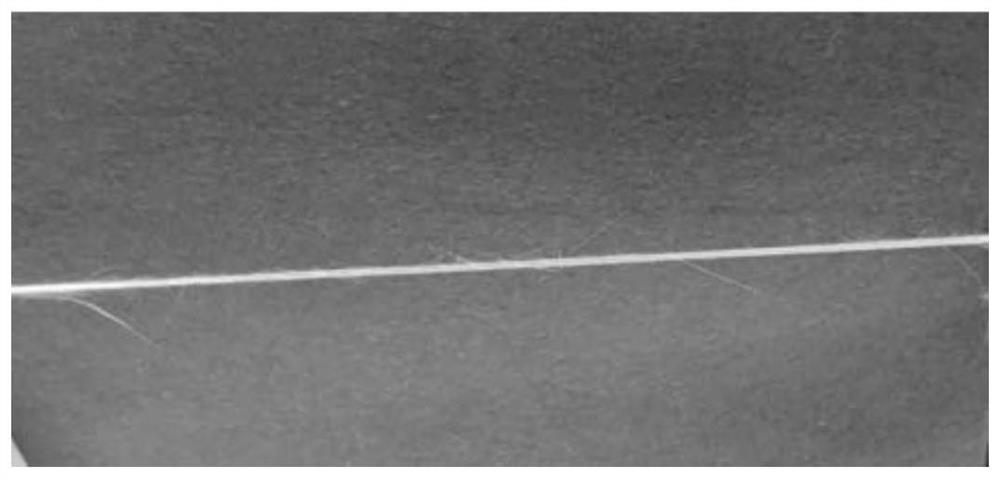

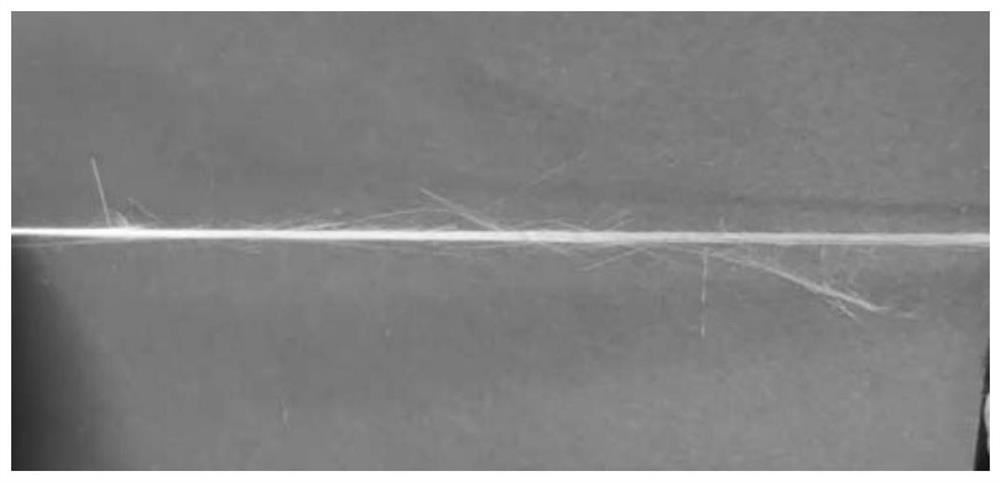

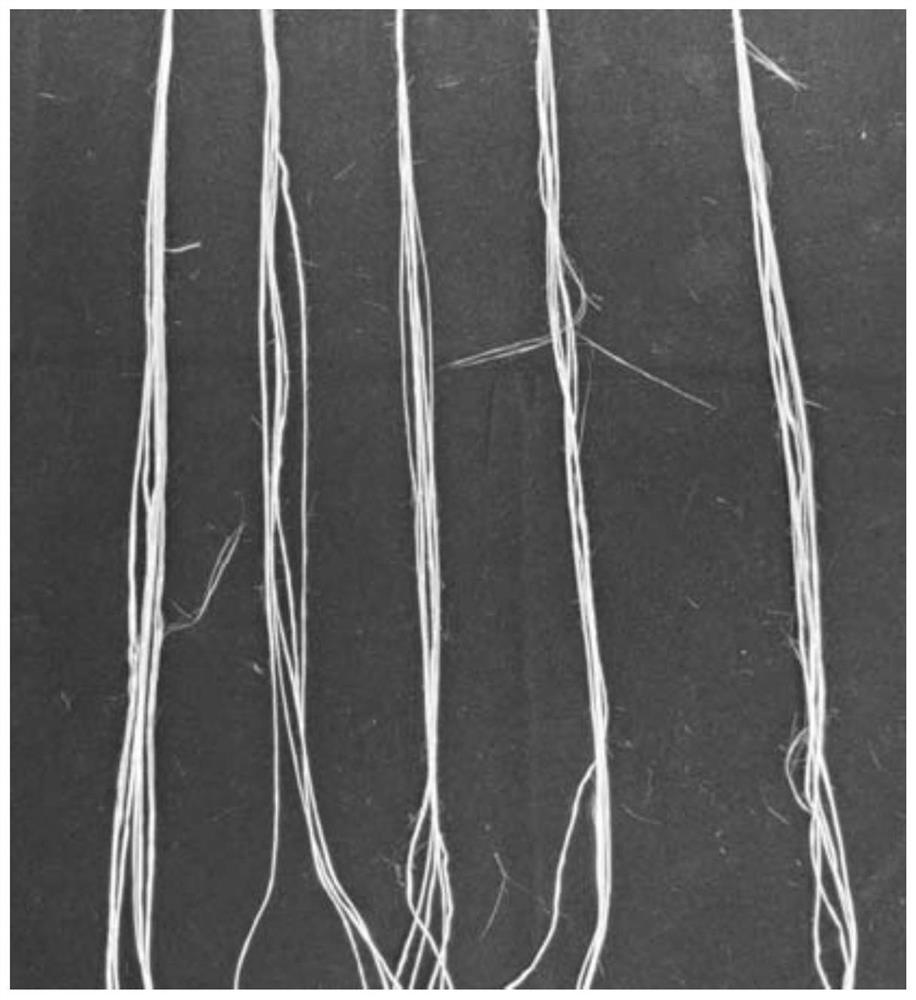

Image

Examples

Embodiment 1

[0029] (1) take by weighing 20g epoxy resin (specifically adopt bisphenol A epoxy resin, model is E44, the same below) and 0.16g butyl glycol ether in reactor, temperature rises to 60 ℃ and stirs until resin viscosity descends;

[0030] (2) continue to feed nitrogen to the reactor to remove air interference, slowly drip 10g diethanolamine and keep stirring, be warming up to 80 DEG C after the dripping is completed, and react 120 minutes;

[0031] (3) be cooled to 60 ℃, drip 6.12g of glacial acetic acid and stir, form neutral solution, and react for 30 minutes;

[0032] (4) add 0.15g n-butyl glycidyl ether and 0.03g silane coupling agent, stir and mix;

[0033] (5) 66 mL of deionized water was added dropwise, and the oil was obtained by continuous stirring.

Embodiment 2

[0035] (1) first take by weighing 102g epoxy resin and 0.78g ethylene glycol butyl ether in the reaction kettle, the temperature rises to 60 ℃ and is stirred and heated until the resin viscosity decreases;

[0036] (2) continue to feed nitrogen to the reactor to remove air interference, slowly drip 55g diethanolamine and keep stirring, be warming up to 80 DEG C after the dripping is completed, and react 90 minutes;

[0037] (3) be cooled to 60 ℃, drip 31g of glacial acetic acid and stir, form neutral solution, and react for 30 minutes;

[0038] (4) add 0.75g n-butyl glycidyl ether and 0.15g silane coupling agent, stir and mix;

[0039] (5) Add 338 g of deionized water dropwise, and continue stirring to obtain the oil.

Embodiment 3

[0041] (1) first take by weighing 80g epoxy resin and 0.6g ethylene glycol butyl ether in the reactor, the temperature rises to 60 ℃ and is stirred and heated to under the resin viscosity;

[0042](2) continue to feed nitrogen to the reactor to remove air interference, slowly drip 42.5g diethanolamine and keep stirring, be warming up to 80 ℃ after the dripping is completed, and react 110 minutes;

[0043] (3) be cooled to 60 ℃, drip 24.5g of glacial acetic acid and stir, form neutral solution, and react for 30 minutes;

[0044] (4) add 0.6g n-butyl glycidyl ether and 0.12g silane coupling agent, stir and mix;

[0045] (5) Add 262 g of deionized water dropwise, and continue stirring to obtain the oil.

[0046] Attention should be paid to the above implementation: the produced oil is a solution with a solid content of about 30%, so as to facilitate the storage and transportation of the oil, and it can be configured to 3-5% according to the required sizing rate for production. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com