A kind of low-temperature curing agent composition for epoxy anticorrosion coating

An epoxy anti-corrosion and curing agent technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor mechanical properties of the cured paint film, unsatisfactory low-temperature curing performance, and sticky surface of the cured paint film. , to achieve the effect of improving compatibility, good adhesion and corrosion resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 prepares the adduct of polyamine

[0023] The polyamine adduct of the present invention is that the polyamine is modified by addition of novolac epoxy resin, and then the unreacted polyamine monomer is removed by vacuuming, and then the obtained adduct is obtained by using a monofunctional compound containing a benzene ring. It is obtained by adding and modifying glycidyl ether of high degree, wherein the ratio of polyamine, novolac epoxy resin, and monofunctional glycidyl ether containing benzene ring is 10-15:1-1.5:1 by weight ~1.5, the polyamine used is one or both of diethylenetriamine and triethylenetetramine.

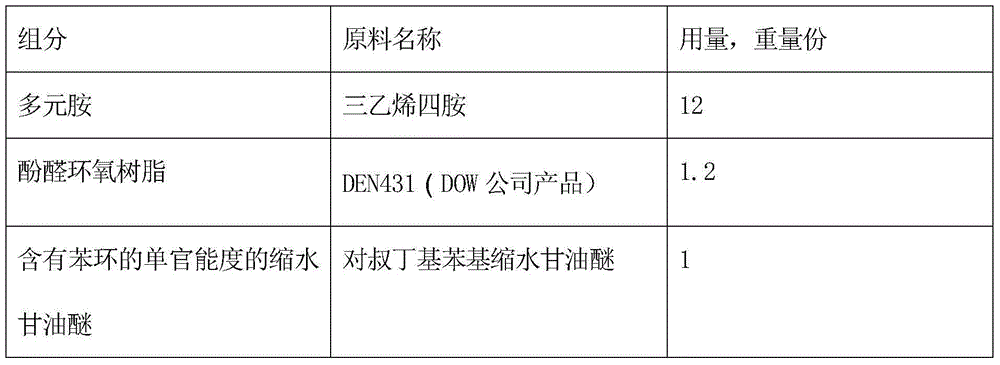

[0024] (1) The dosage of each raw material is shown in Table 1.

[0025] Table 1

[0026]

[0027] (2) Preparation method

[0028] ① First, add 12 parts by weight of polyamine to the reaction kettle, stir at a speed of 600-800 rpm, and heat to 40-45°C in a water bath;

[0029] ② After diluting 1.2 parts by weight of novolac epoxy resin w...

Embodiment 2

[0033] Embodiment 2 prepares the Mannich base of polyamine

[0034] The Mannich base of the polyamine of the present invention is that polyamine reacts with the phenolic compound containing long carbon chain, 37wt% formaldehyde aqueous solution and obtains, the weight part of the phenolic compound containing long carbon chain, polyamine, 37wt% formaldehyde solution The ratio is 10:4~6:2~3, wherein the polyamine is a mixture of m-xylylenediamine and trimethylhexamethylenediamine;

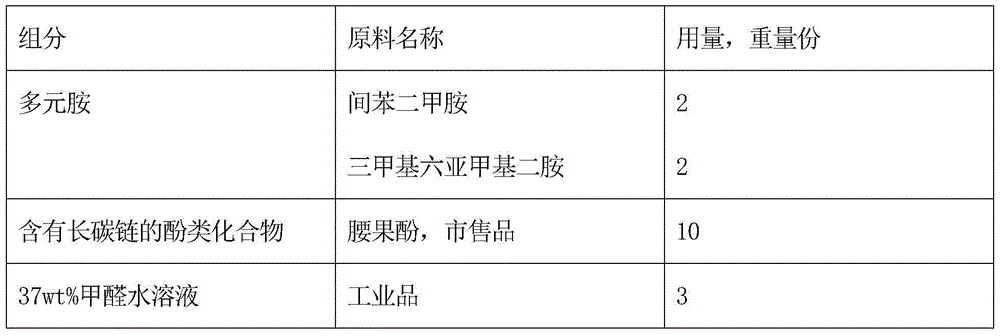

[0035] (1) The specific formula is shown in Table 2.

[0036] Table 2

[0037]

[0038] (2) Preparation method:

[0039] Under normal temperature conditions, add phenolic compounds containing long carbon chains, polyamines and 37wt% formaldehyde aqueous solution at a weight ratio of 10:4:3 to the reaction vessel, then heat up to 80-85°C and react at this temperature for 5 For ~6 hours, keep stirring at 600-800 rpm during the heating and heat preservation process, and distill and dehydrate at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com