Merrifield resin loaded polyether amide ionic liquid catalyst and preparation method thereof

An ionic liquid and polyether amide technology, which is applied in the field of polyether amide ionic liquid catalyst and its preparation, can solve the problems of low catalytic activity, weak catalyst activation effect, limited application of supported ionic liquid catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

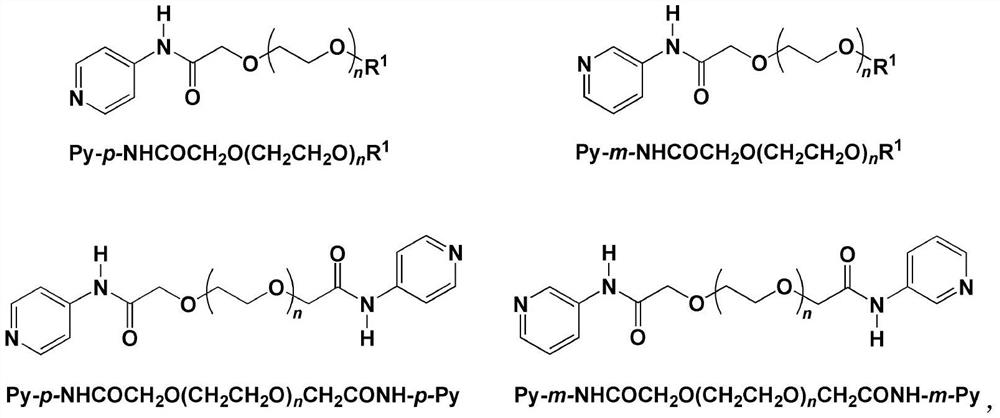

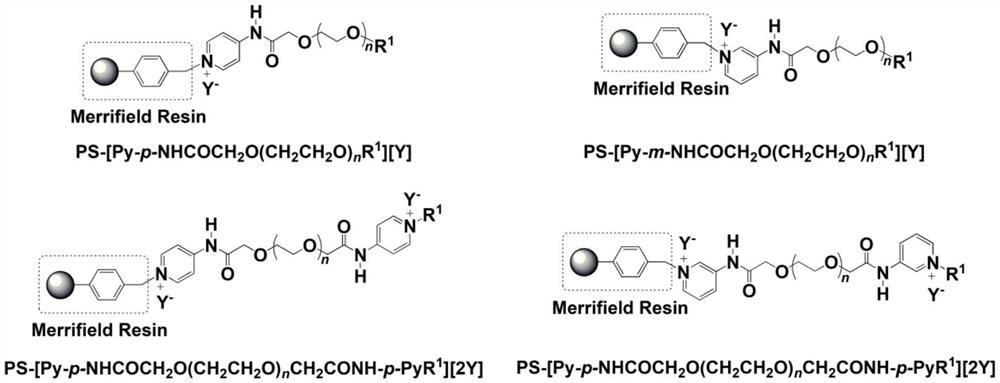

[0020] Polyether Monoamide Ionic Liquid Catalyst PS-[Py-p-NHCOCH Supported by Merrifield Resin Material 2 O(CH 2 CH 2 O) 15 CH 3 ][Cl] (n=15, R 1 =CH 3 , the preparation of Y=Cl)

[0021] Swell 2g Merrifield resin in toluene at room temperature for 12h, add 15ml acetonitrile solution and 3.5g p-aminopyridine polyether monoamide Py-p-NHCOCH after filtration 2 O(CH 2 CH 2 O) 15 CH 3 , under an inert atmosphere, reacted at 80°C for 24h, cooled to room temperature, separated by filtration, washed the resin with ethanol, and dried to obtain the polyether monoamide ionic liquid catalyst PS-[Py-p-NHCOCH supported by Merrifield resin material 2 O(CH 2 CH 2 O) 15 CH 3 ][Cl].

Embodiment 2

[0023] Polyether Monoamide Ionic Liquid Catalyst PS-[Py-p-NHCOCH Supported by Merrifield Resin Material 2 O(CH 2 CH 2 O) 15 CH 3 ][Br] (n=15, R 1 =CH 3 , Y=Br) preparation

[0024] The polyether monoamide ionic liquid catalyst PS-[Py-p-NHCOCH of the Merrifield resin material load that embodiment 1 obtains 2 O(CH 2 CH 2 O) 15 CH 3 ][Cl] was dispersed in 20mL deionized water, then 4.3g NaBr was added, and ion exchange was carried out at 30°C for 48h to obtain the polyether monoamide ionic liquid catalyst PS-[Py-p-NHCOCH supported by Merrifield resin material 2 O(CH 2 CH 2 O) 15 CH 3 ][Br].

Embodiment 3

[0026] Polyether Monoamide Ionic Liquid Catalyst PS-[Py-p-NHCOCH Supported by Merrifield Resin Material 2 O(CH 2 CH 2 O) 15 CH 3 ][I](n=15, R 1 =CH 3 , the preparation of Y=I)

[0027] The polyether monoamide ionic liquid catalyst PS-[Py-p-NHCOCH of the Merrifield resin material load that embodiment 1 obtains 2 O(CH 2 CH 2 O) 16 CH 3 ][Cl] was dispersed in 20mL deionized water, then 6.3g NaI was added, and ion exchange was carried out at 30°C for 48h to obtain the polyether monoamide ionic liquid catalyst PS-[Py-p-NHCOCH supported by Merrifield resin material 2 O(CH 2 CH 2 O) 15 CH 3 ][I].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com