Environment-friendly degradable packaging bottle and preparation method thereof

A green and environmentally friendly packaging bottle technology, applied in the field of plastic bottles, can solve the problems of accelerated aging of degradable plastics, unfavorable use of degradable materials, and decline in mechanical properties, so as to improve biodegradability and biocompatibility, and improve biodegradability. Degradability and the effect of improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

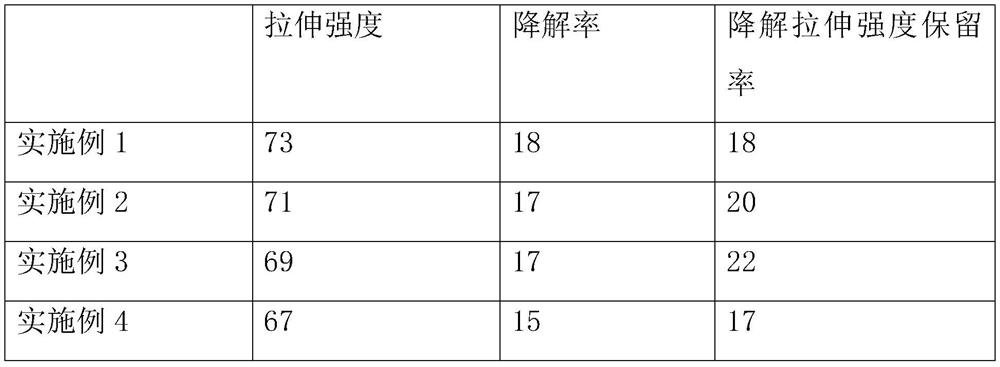

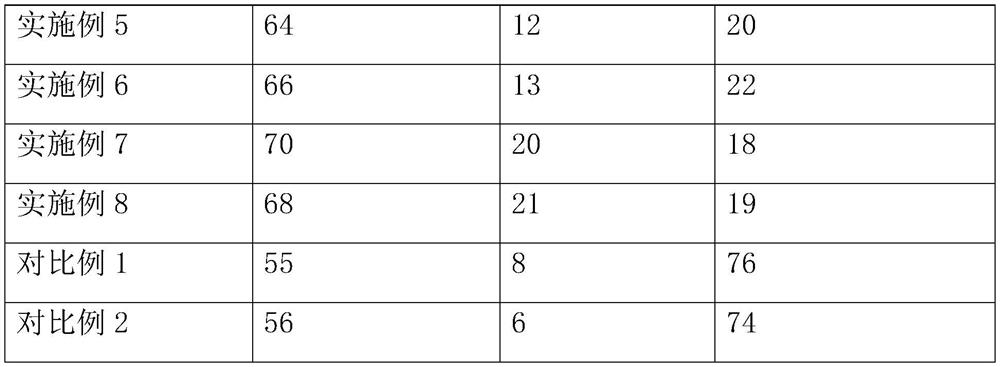

Examples

Embodiment 1

[0044] A green and environmentally friendly degradable packaging bottle, including components of the following qualities:

[0045] 100 kg of polylactic acid, 25 kg of polybutylene succinate, 15 kg of 3-maleimido propionic acid, 0.2 kg of triethanolamine, 0.05 kg of triphenyl phosphate, and 0.1 kg of triethyl phosphate.

[0046] It is prepared by the following steps:

[0047] Step 1, the maleic anhydride compound is mixed with triethanolamine to adjust the pH to 9, then heated to 70° C., and ultrasonicated for 20 minutes.

[0048] Step 2, mix polylactic acid, 3-maleimidopropionic acid, polybutylene succinate, triphenyl phosphate, and triethyl phosphate, adjust the pH to 9, and set the temperature at 180r / min , stirred for 4min to obtain the mixture;

[0049] Step 3, then heat the mixture in the screw extruder for 30 minutes and 180°C to make the mixture in a molten state, control the molding pressure to 62kg, and the air pressure to 6kg for blow molding.

Embodiment 2

[0051] A green and environmentally friendly degradable packaging bottle, including components of the following qualities:

[0052] 100kg of polylactic acid, 30kg of polybutylene succinate, 16kg of 3-maleimidopropionic acid, 0.3kg of triethanolamine, 0.03kg of triphenyl phosphate, and 0.12kg of triethyl phosphate.

[0053] It is prepared by the following steps:

[0054] Step 1, the maleic anhydride compound is mixed with triethanolamine to adjust the pH to 9.5, then heated to 65° C., and ultrasonicated for 15 minutes.

[0055] Step 2, mix polylactic acid, 3-maleimidopropionic acid, polybutylene succinate, triphenyl phosphate, and triethyl phosphate, adjust the pH to 9.5, and set the temperature at 220r / min , stirred for 3 minutes to obtain the mixture;

[0056] Step 3, then heat the mixture in the screw extruder for 33 minutes and 190°C to make the mixture in a molten state, control the molding pressure to 58kg, and the air pressure to 5.8kg for blow molding.

Embodiment 3

[0058] A green and environmentally friendly degradable packaging bottle, including components of the following qualities:

[0059] 100kg of polylactic acid, 20kg of polybutylene succinate, 12kg of 3-maleimidopropionic acid, 0.2kg of triethanolamine, 0.08kg of triphenyl phosphate, and 0.12kg of triethyl phosphate.

[0060] It is prepared by the following steps:

[0061] Step 1, the maleic anhydride compound is mixed with triethanolamine, the pH is adjusted to 8.5, then heated to 75° C., and ultrasonicated for 15-25 minutes.

[0062] Step 2, mix polylactic acid, 3-maleimidopropionic acid, polybutylene succinate, triphenyl phosphate, and triethyl phosphate, adjust the pH to 8.5, and set the temperature at 200r / min , stirred for 5 minutes to obtain a mixture;

[0063] Step 3, then heat the mixture in the screw extruder for 26 minutes to 170-190°C to make the mixture in a molten state, control the mold pressure to 65kg, and the air pressure to 6.5kg for blow molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com