Ultraviolet-visible microobjective optical system for wafer AOI detection

A technology of microscope objective lens and optical system, applied in the field of ultraviolet-visible microscope objective lens optical system and optical system, can solve the problems of limited detection efficiency, small field of view on the object side, image quality influence, etc., to achieve high-resolution characteristics, The effect of reducing the amount of introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

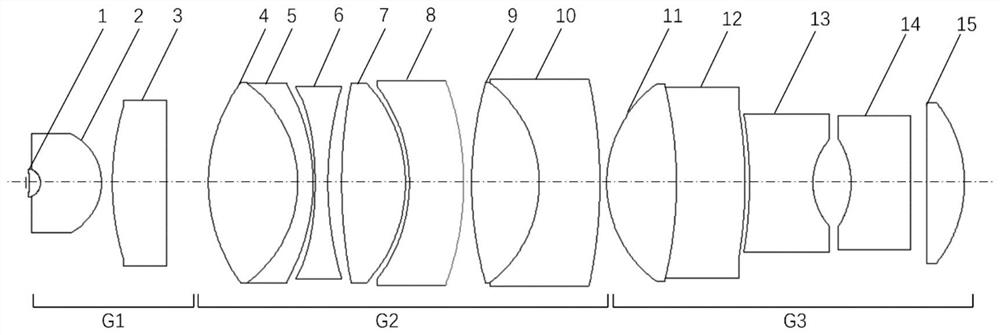

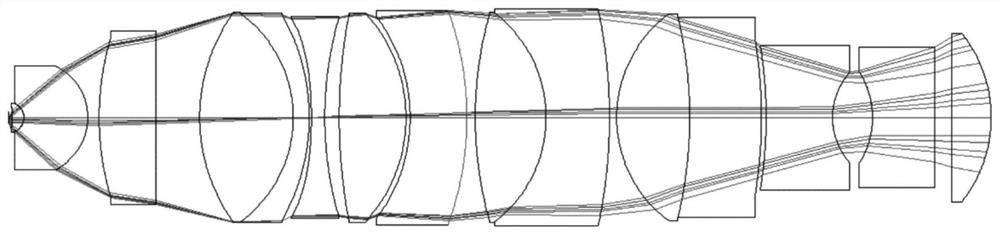

[0035] Example: A UV-Vis microscope objective optical system for wafer AOI inspection, such as figure 1 As shown, the object side is defined as the left side, and the image side is defined as the right side. Since the optical path is reversible, according to the reverse optical path design, the optical system of the microscope objective lens is along its optical axis direction from the object side to the image side, including the positive diopter in turn. The first lens group G1 (front group), the second lens group G2 (middle group) with positive diopter, and the third lens group G3 (rear group) with negative diopter, wherein:

[0036] The first lens group sequentially includes along its optical axis from the object side to the image side: a first lens 1 with positive refractive power, a second lens 2 with positive refractive power, and a third lens 3 with positive refractive power;

[0037]The second lens group sequentially includes along its optical axis from the object side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| optical path length | aaaaa | aaaaa |

| optical path length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com