Modified high-nickel ternary positive electrode material as well as preparation method and application thereof

A cathode material, high nickel technology, applied in electrical components, battery electrodes, structural parts, etc., can solve the problems of poor thermal stability and cycle stability, and achieve the effects of good cycle performance, high specific capacity, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

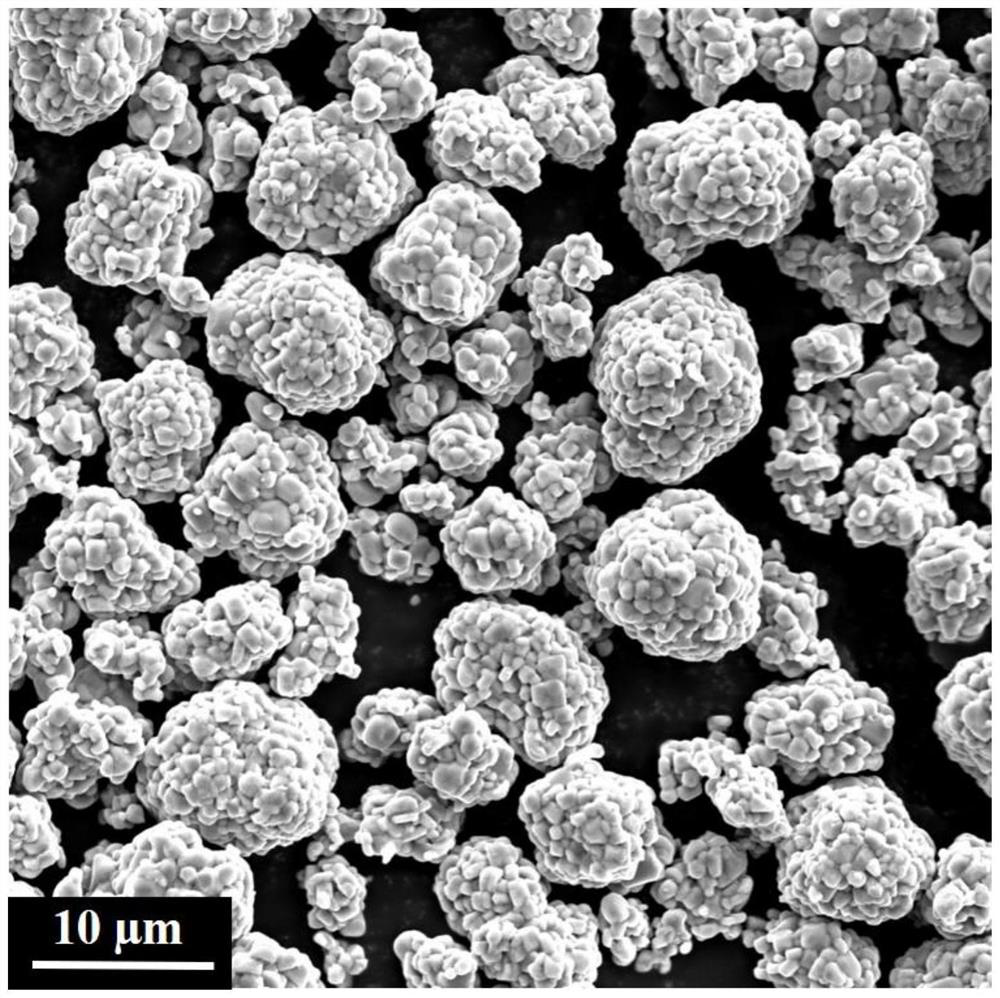

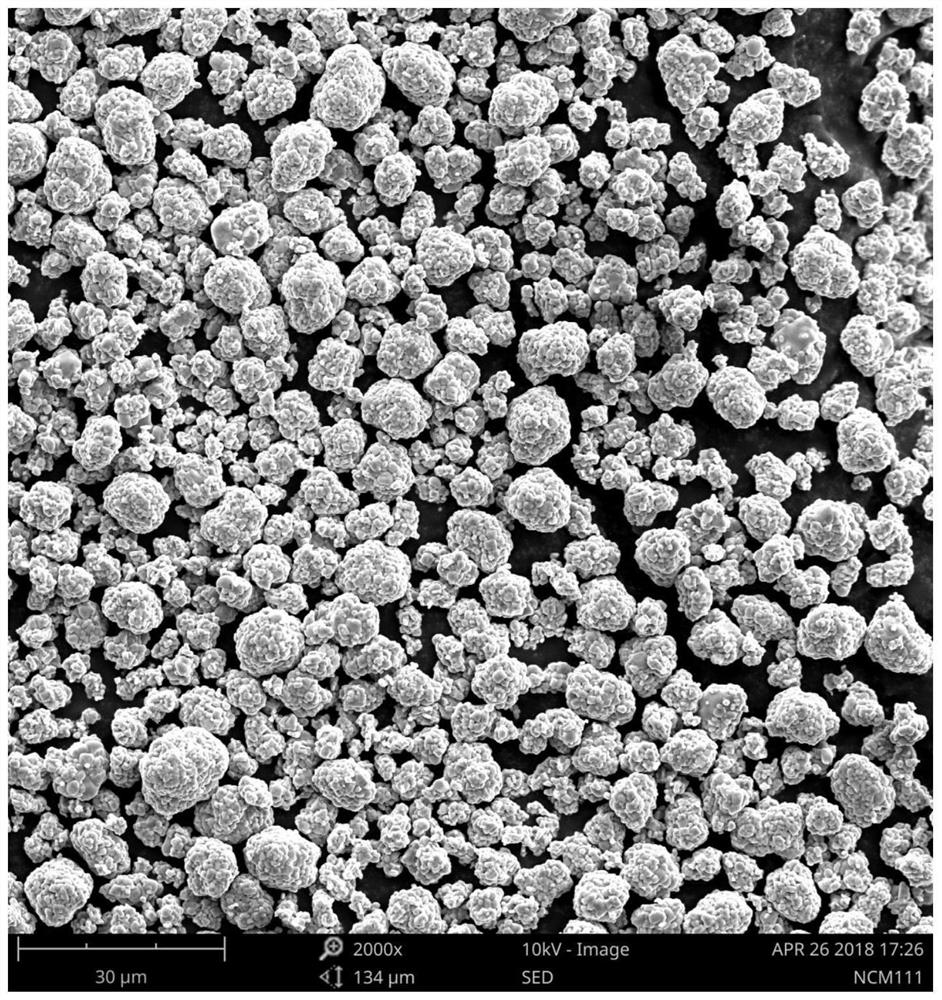

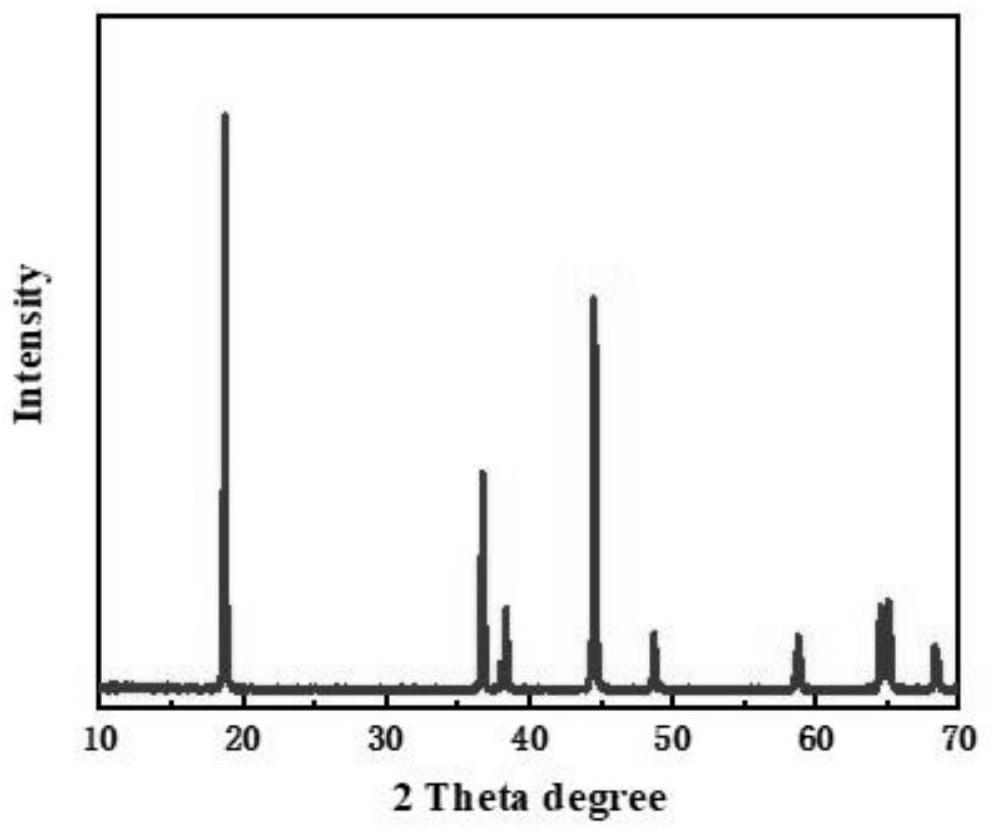

Image

Examples

Embodiment 1

[0041] A method for preparing a modified high-nickel ternary positive electrode material, comprising the following steps:

[0042] (1) Vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 (0.6≤x≤0.9) Matrix preparation:

[0043] S1, the Ni (NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 and ammonium vanadate were dissolved in deionized water and stirred for 6 hours, and then citric acid was added dropwise to obtain a mixed solution. The mixed solution was first stirred at 90 °C for 14 hours for gelation, and then dried in an oven until the water completely evaporated. , to obtain the pretreatment;

[0044] Among them, Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 The molar ratio is 6:2:2;

[0045] S2. Mix the pretreatment of step S1 with lithium nitrate uniformly, first sinter at 450°C for 3h, then keep at 750°C for 12h, and cool down naturally to obtain vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 matrix;

[0046] Among them, Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 ...

Embodiment 2

[0050] A method for preparing a modified high-nickel ternary positive electrode material, comprising the following steps:

[0051] (1) Vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 (0.6≤x≤0.9) Matrix preparation:

[0052] S1, the NiSO 4 , CoSO 4 , MnSO 4 and ammonium vanadate were dissolved in deionized water and stirred for 4 hours, and then citric acid was added dropwise to obtain a mixed solution. The mixed solution was first stirred at 80 °C for 13 hours for gelation, and then dried in an oven until the water completely evaporated. , to obtain the pretreatment;

[0053] Among them, NiSO 4 , CoSO 4 , MnSO 4 The molar ratio is 8:1:1;

[0054] S2. Mix the pretreatment of step S1 with lithium carbonate uniformly, sinter at 400 °C for 3 hours, then keep at 800 °C for 10 hours, and cool down naturally to obtain vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 matrix;

[0055] Among them, NiSO 4 , CoSO 4 , MnSO 4 The molar ratio of the total substance to lithi...

Embodiment 3

[0059] A method for preparing a modified high-nickel ternary positive electrode material, comprising the following steps:

[0060] (1) Vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 (0.6≤x≤0.9) Matrix preparation:

[0061] S1, the Ni (CH 3 COO) 2 , Co(CH 3 COO) 2 , Mn(CH 3 COO) 2 and ammonium vanadate were dissolved in deionized water and stirred for 8 hours, and then citric acid was added dropwise to obtain a mixed solution. The mixed solution was first stirred at 100 ° C for 12 hours, and then dried in an oven until the water completely evaporated to obtain a pretreatment product. ;

[0062] Among them, Ni(CH 3 COO) 2 , Co(CH 3 COO) 2 , Mn(CH 3 COO) 2 The molar ratio is 9:0.5:0.5;

[0063] S2. Mix the pretreatment of step S1 with lithium nitrate uniformly, first sinter at 500°C for 3h, then keep at 700°C for 14h, and cool down naturally to obtain vanadium-doped LiNi x Co (1-x) / 2 Mn (1-x) / 2 O 2 matrix;

[0064] Among them, Ni(CH 3 COO) 2 , Co(CH 3 CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com